A high-temperature cracking furnace for odorless, anti-blocking and energy-saving domestic waste

A high-temperature pyrolysis and domestic waste technology, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of secondary pollution, waste of resources, high labor intensity, etc., and achieve the effects of good sealing performance, energy saving, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

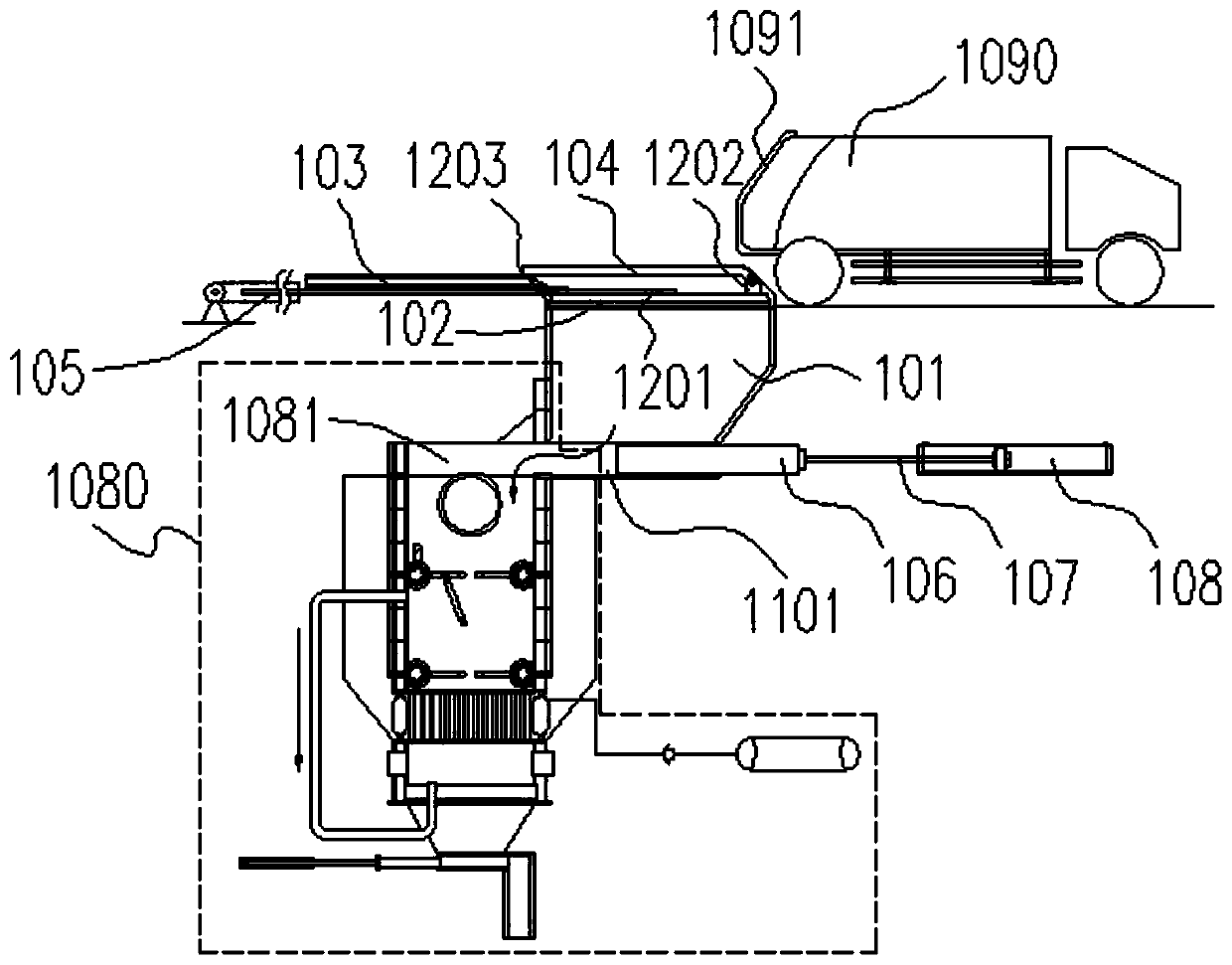

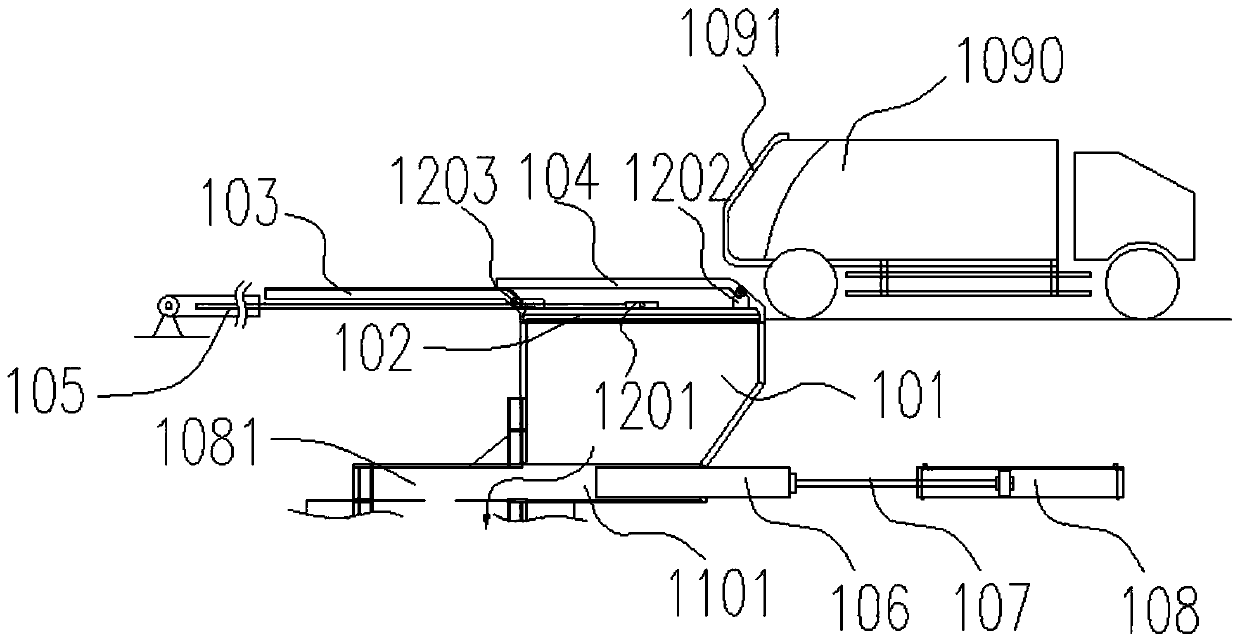

[0041] In order to enable those skilled in the art to better understand the technical solution of the utility model, the utility model will be described in detail below in conjunction with the accompanying drawings. The description of this part is only exemplary and explanatory, and should not have any influence on the protection scope of the utility model. restrictive effect.

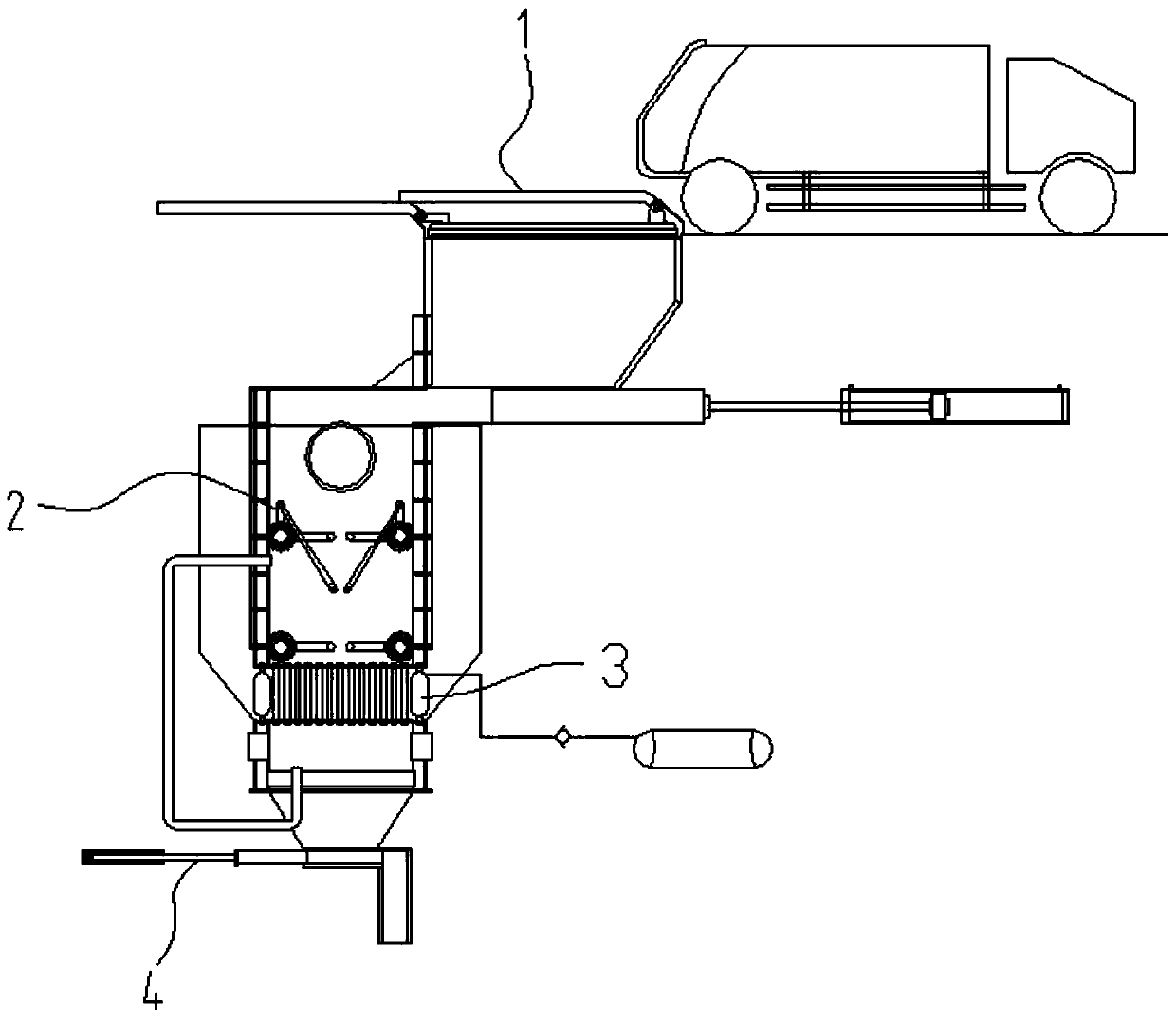

[0042] Such as Figure 1-Figure 8 As shown, the concrete structure of the present utility model is: it comprises feeding system 1, and its lower end is provided with garbage isolation cracking system 2; The lower end of described garbage isolation cracking system 2 is pyrolysis and waste heat recovery system 3; A slagging system 4 is provided at the lower end of the waste heat recovery system 3 .

[0043] Preferably, the feed system 1 includes a garbage storage bin 101, and the garbage storage bin 101 is arranged above the cracking furnace 1080; The bottom of the warehouse 101 is provided with a garb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com