Aromatic polyamide hollow fiber membrane, preparation method and application

A technology of aromatic polyamide and fiber membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor heat resistance, poor antibacterial property, and affect the performance of membrane products, and achieve thermodynamic compatibility Good, stable interface, not easy to grow fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

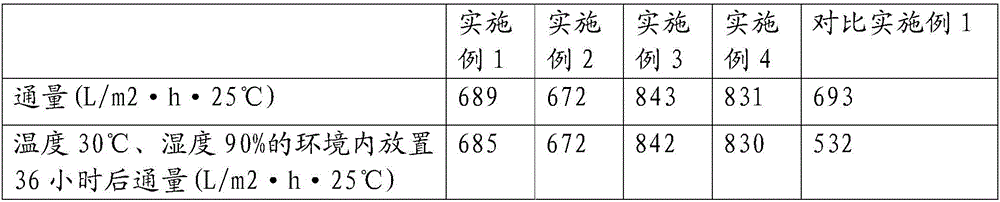

Examples

Embodiment 1

[0020] Embodiment 1: A kind of preparation method of aromatic polyamide hollow fiber membrane adopts the following steps:

[0021] 1) Configure the casting solution; the casting solution includes the following components in parts by weight: 30 g of meta-aramid fiber of aromatic polyamide material, compound solvent (dimethylsulfoxide:lithium chloride=4:1 ) 35g, additive vinylpyrrolidone 35g and nano-silver ion 1g;

[0022] 2) Add the casting solution prepared in step 1) into the screw extruder by thermal phase separation method, melt and extrude through the spinneret at 240°C, enter the water bath for solidification and molding, and heat through winding and drawing High temperature resistant polyamide hollow fiber membranes are made through post-treatment process of hollow fiber membranes. The process parameters of other process sections are the same as the current thermally induced phase separation process for membrane production.

Embodiment 2

[0023] The preparation method of embodiment 2 is the same as that of embodiment 1, the only difference is that the components of step 1) casting solution are: 35g of para-aramid fiber, and solvent (dimethylacetamide: calcium chloride=6:1 ) 30g, additive vinylpyrrolidone 30g and nano-silver ions 3g; the melt extrusion temperature of step 2) is 260°C.

Embodiment 3

[0024] The preparation method of embodiment 3 is the same as that of embodiment 1, the only difference is that the components of step 1) casting solution are: 32g of meta-aramid fibers, and solvent (dimethylacetamide: lithium chloride=5:1 ) 20g, additive vinylpyrrolidone 50g and nano-silver ions 5g; the melt extrusion temperature of step 2) is 255°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com