Preparation method and application of carbon sphere/Au nanometer composite material

A technology of nanocomposite materials and carbon spheres, which is applied in the field of preparation of nanocomposite materials, can solve the problems affecting the catalytic performance and service life of materials, and achieve the effects of superior catalytic performance, uniform loading, and simple reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

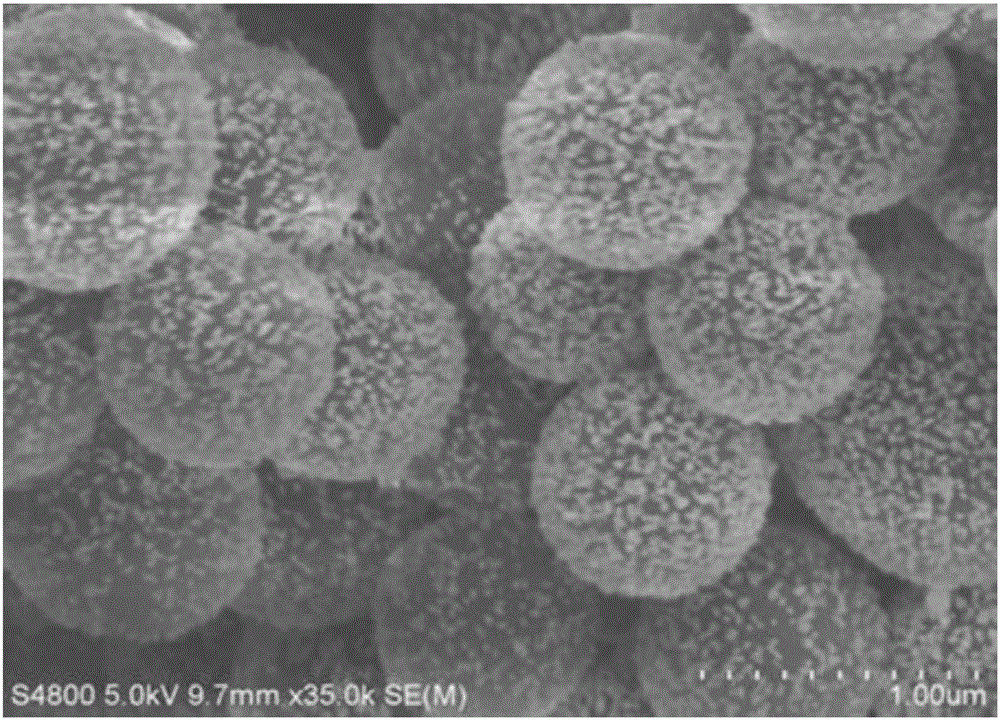

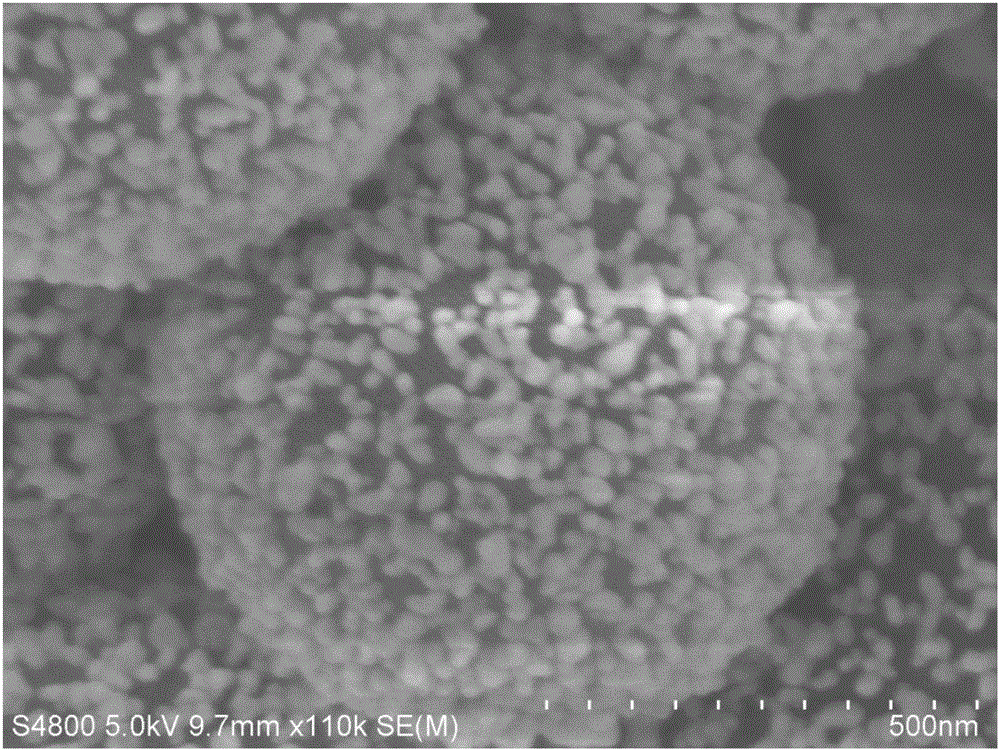

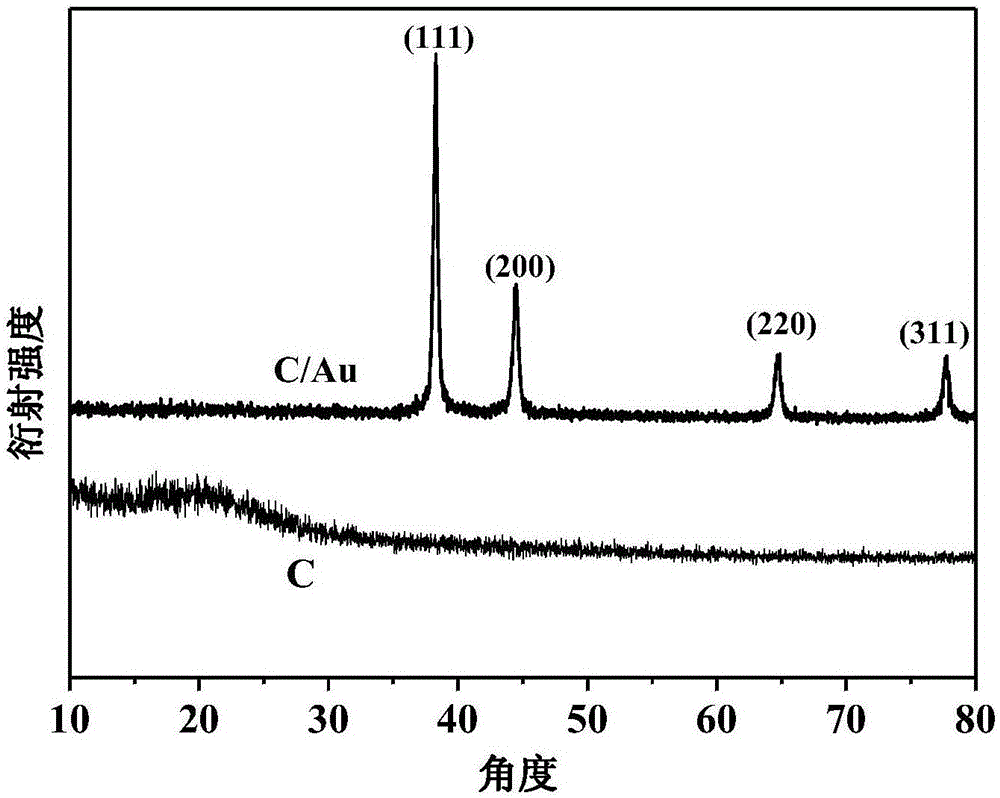

[0035] A method for preparing a carbon sphere / Au nanocomposite material, comprising a preparation process of carbon spheres, a modification process of carbon spheres, and a loading process of Au nanoparticles. The specific steps of the preparation method are as follows:

[0036] a. Weigh 0.05g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 20mL of distilled water, add 2g of glucose during magnetic stirring, stop stirring after it is completely dissolved, and pour the above solution into 25mL of distilled water Put it in a reaction kettle, put it in an oven, heat up to 170°C, react for 12 hours, cool to room temperature, centrifuge to obtain a precipitate, wash it several times with deionized water and absolute ethanol, and dry it in a vacuum oven at 60°C to constant weight , to get carbon spheres;

[0037] b. Weigh 15 mg of carbon spheres prepared in step a and dissolve in 30 mL of distilled water, add 1.7532 g of NaCl and 1 mL of polydiallyldimethylammonium chlor...

Embodiment 2

[0045] A method for preparing a carbon sphere / Au nanocomposite material, comprising a preparation process of carbon spheres, a modification process of carbon spheres, and a loading process of Au nanoparticles. The specific steps of the preparation method are as follows:

[0046] a. Weigh 0.05g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 20mL of distilled water, add 2g of glucose during magnetic stirring, stop stirring after it is completely dissolved, and pour the above solution into 25mL of distilled water Put it in a reaction kettle, put it in an oven, heat up to 170°C, react for 12 hours, cool to room temperature, centrifuge to obtain a precipitate, wash it several times with deionized water and absolute ethanol, and dry it in a vacuum oven at 60°C to constant weight , to get carbon spheres;

[0047] b. Weigh 15 mg of carbon spheres prepared in step a and dissolve in 30 mL of distilled water, add 1.7532 g of NaCl and 0.5 mL of polydiallyldimethylammonium chl...

Embodiment 3

[0052] A method for preparing a carbon sphere / Au nanocomposite material, comprising a preparation process of carbon spheres, a modification process of carbon spheres, and a loading process of Au nanoparticles. The specific steps of the preparation method are as follows:

[0053] a. Weigh 0.05g of cetyltrimethylammonium bromide (CTAB) and dissolve it in 20mL of distilled water, add 2g of glucose during magnetic stirring, stop stirring after it is completely dissolved, and pour the above solution into 25mL of distilled water Put it in a reaction kettle, put it in an oven, heat up to 170°C, react for 12 hours, cool to room temperature, centrifuge to obtain a precipitate, wash it several times with deionized water and absolute ethanol, and dry it in a vacuum oven at 60°C to constant weight , to get carbon spheres;

[0054] b. Weigh 15 mg of carbon spheres prepared in step a and dissolve them in 30 mL of distilled water, add 1.7532 g of NaCl and 1.5 mL of polydiallyldimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com