Method and device used for producing ethyl methyl carbonate by adopting azeotropic-reaction fractionating adjacent tower method

A technology of ethyl methyl carbonate and reactive distillation, applied in the purification/separation of carbonate/haloformate, preparation of organic carbonate, organic chemistry, etc., can solve the difficulty of increasing separation and purification and limit industrial application , increase production costs and other issues, to achieve the effect of reducing equipment investment and energy consumption, simplifying processes, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

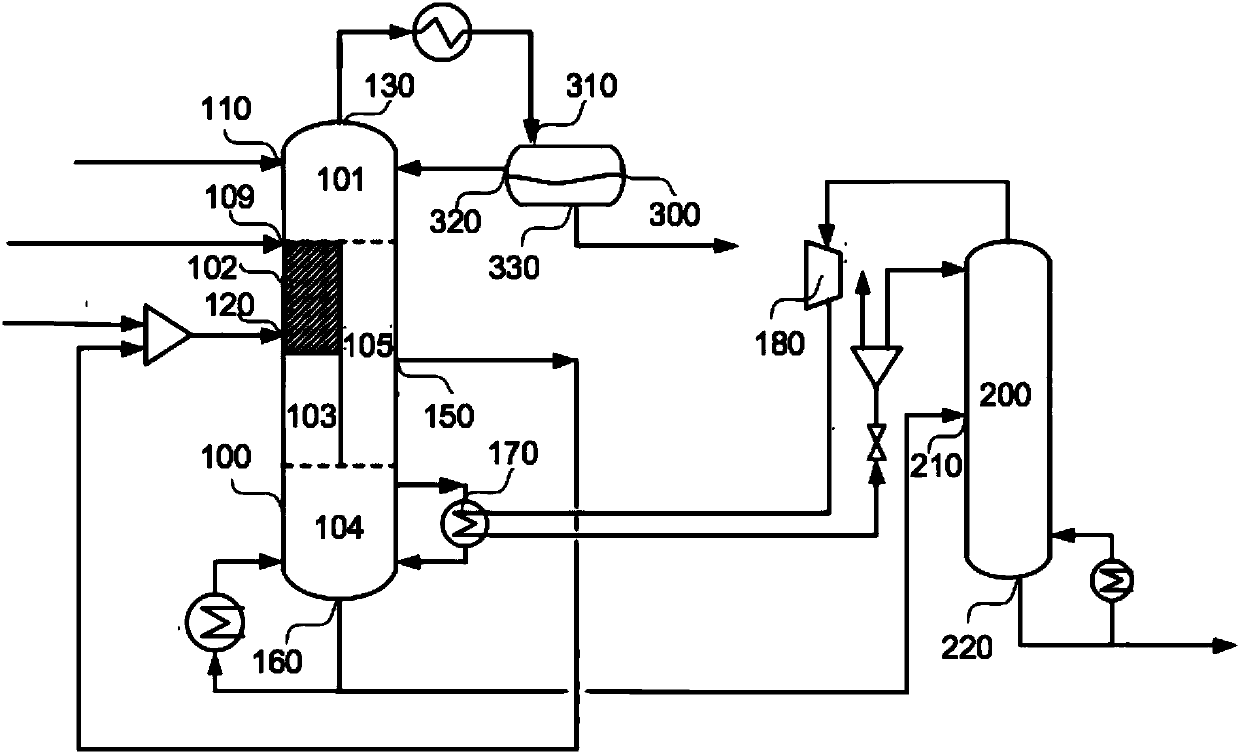

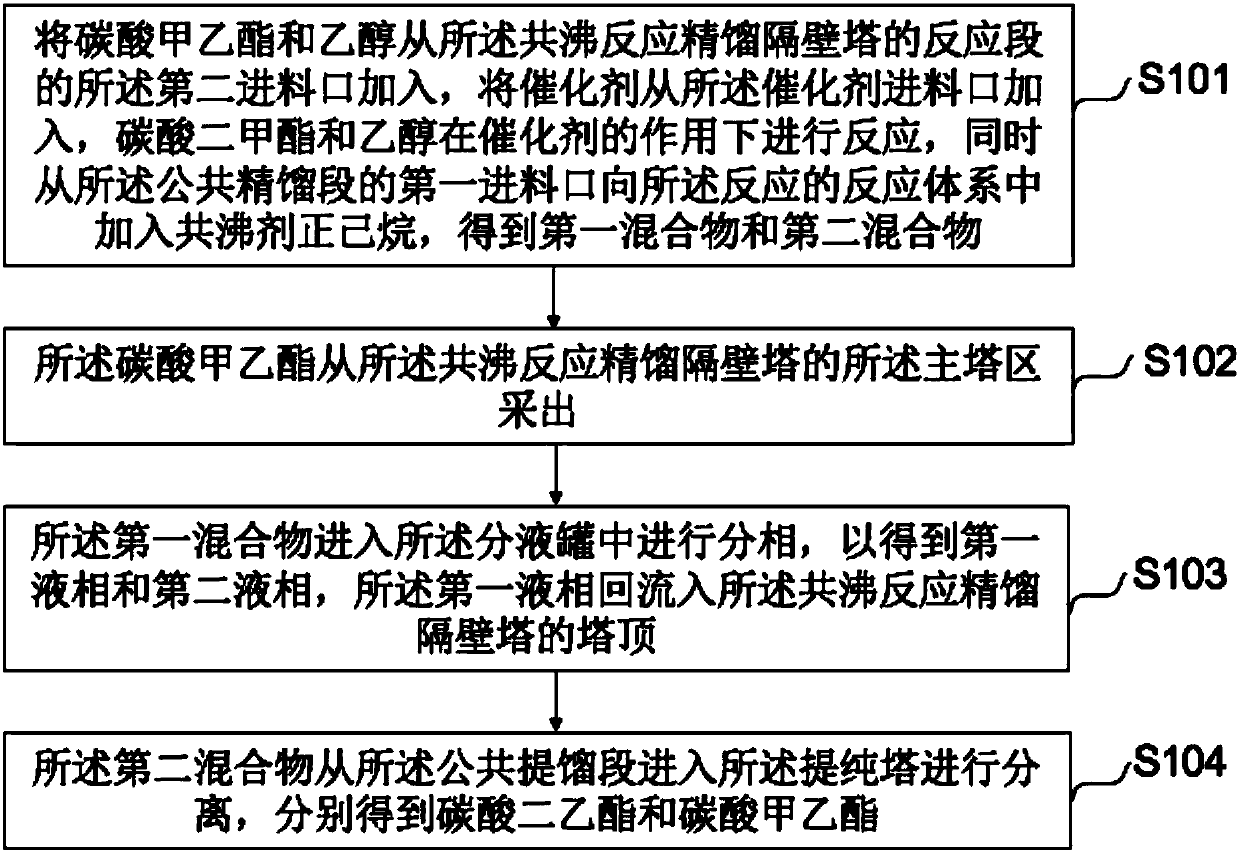

[0046] According to the method and the device that azeotropic reaction rectification dividing wall column method produces ethyl methyl carbonate of the present invention, concrete flow process is as follows:

[0047] Supplementary entrainer n-pentane is fed from the top of the azeotropic reaction rectification dividing wall column, followed by the top steam into the condenser for condensation, and the condensed stream enters the liquid separation tank for phase separation, and the first liquid phase is n-pentane The mixture with dimethyl carbonate is used as tower top reflux, and the second liquid phase is high-purity methanol directly extracted as tower top product, and the side line product of the next-wall tower is mainly dimethyl carbonate recycled back to the azeotropic reaction rectification second-wall tower for utilization. A side stream from the middle of the common stripping section is heated by an intermediate reboiler and then returned to the tower. The bottom produ...

Embodiment 2

[0056] Identical with technological process described in embodiment 1, difference is that catalyzer is potassium hydroxide in the azeotropic reaction rectifying dividing wall column, and the mol ratio of dimethyl carbonate and ethanol in stream dimethyl carbonate and ethanol is 2.5:1 .

[0057] The operating pressure of the separatory tank is 0.1 MPa, and the temperature is 33°C. The azeotropic reaction rectification dividing wall column is a packed column, and the common rectification section theoretical plate of the azeotropic reaction rectification dividing wall column is 6 pieces, the reaction section theoretical plate is 10 pieces, the initial distillation zone theoretical plate is 20 pieces, and the public stripping section There are 7 theoretical boards, and 20 theoretical boards in the main tower area. The operating pressure of the tower is 0.1MPa, the temperature at the top of the tower is 53°C, and the temperature at the bottom of the tower is 108°C. The dimethyl ca...

Embodiment 3

[0063] Identical with technological process described in embodiment 1, difference is that catalyzer is lithium carbonate in the azeotropic reaction rectifying dividing wall column, and the mol ratio of dimethyl carbonate and ethanol in the stream dimethyl carbonate and ethanol (100) is 3 :1.

[0064] The operating pressure of the separatory tank is 0.25MPa, and the temperature is 40°C. The azeotropic reaction rectification dividing wall tower is a plate tower, and the public rectification section theoretical plate of the azeotropic reaction rectification dividing wall tower (111) is 10, the reaction section theoretical plate is 12, and the initial distillation zone theoretical plate is 38. There are 15 theoretical plates in the stripping section and 38 theoretical plates in the main tower area. The operating pressure of the tower is 0.3MPa, the temperature at the top of the tower is 92°C, and the temperature at the bottom of the tower is 140°C. The dimethyl carbonate product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com