Method for preparing high-vinyl butadiene-styrene copolymer by adopting molybdenum-series catalytic system

A high-vinyl styrene-butadiene copolymer and catalytic system technology, applied in the field of polymer synthesis, can solve the problems of low styrene activity, low styrene polymerization activity, and low styrene content, and achieve low gel content, good Processability, effect of low glue viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiments 1 to 41 are specific implementations of a method for preparing high vinyl styrene-butadiene copolymers using a molybdenum-based catalytic system of the present invention. Wherein embodiment 1 is the best embodiment.

Embodiment 1~6

[0035] This group of examples is a copolymerization reaction of different dosages of TBP ligands.

[0036] A solution prepared by sequentially adding toluene, styrene (St), and butadiene (Bd) into an anhydrous and oxygen-free 20mL reaction flask, the monomer concentration is [M]=3.04×10 -3 mol / mL, W St / W Bd =1 / 3, and then add m-cresol aluminum cocatalyst, main catalyst with different P / Mo ratio and polar additives. Where Al / Mo=5, Mo / Bd=1×10 -3 , dioxane / Mo=0.5. After polymerization at 70°C for 9 hours, terminate the reaction with 1.5-2.0 mL of absolute ethanol, add ethanol to precipitate the copolymer, and dry to remove the solvent.

[0037] Table 1

[0038] .

Embodiment 7~11

[0040] The embodiment of this group is the copolymerization reaction with different dosages of Mo as the main catalyst.

[0041] The experiment was carried out in a sealed nitrogen-protected 20mL polymerization tube, and a solution made of toluene, styrene, and butadiene was added in sequence, and the monomer concentration was [M]=3.04×10 -3 mol / mL, W St / W Bd =1 / 3, then add m-cresol aluminum cocatalyst and polar additive, main catalyst (wherein P / Mo=4), Al / Mo=5, dioxane / Mo=0.5. After polymerization at 70°C for 9 hours, terminate the reaction with 1.5-2.0 mL of absolute ethanol, add ethanol to precipitate the copolymer, and dry to remove the solvent.

[0042] Table 2

[0043] .

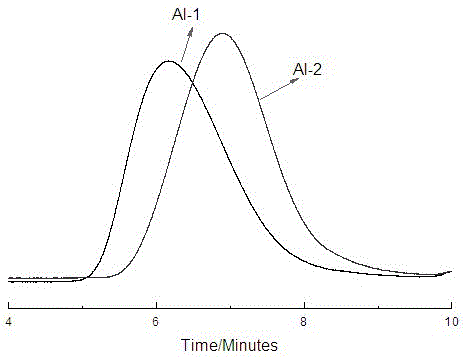

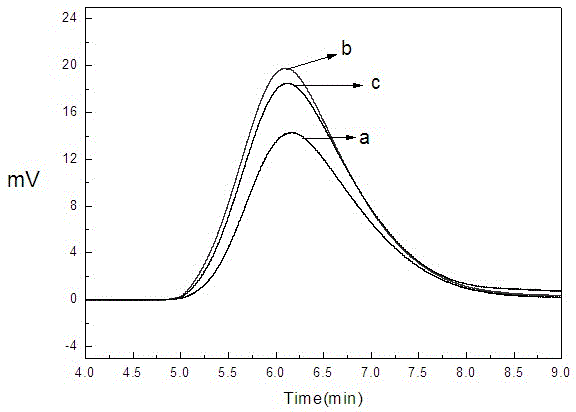

[0044] attached by figure 1 The polymer obtained by the GPC test is a unimodal distribution, and the molecular weight of the polymer and its molecular weight distribution are shown in the table below.

[0045] table 3

[0046] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com