Wear-resistant plastic bag and processing technology therefor

A processing technology and plastic bag technology, applied in the field of plastic product processing, can solve the problems of white pollution and serious plastic bags, and achieve the effect of low cost, high mechanical strength, and simple and convenient processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

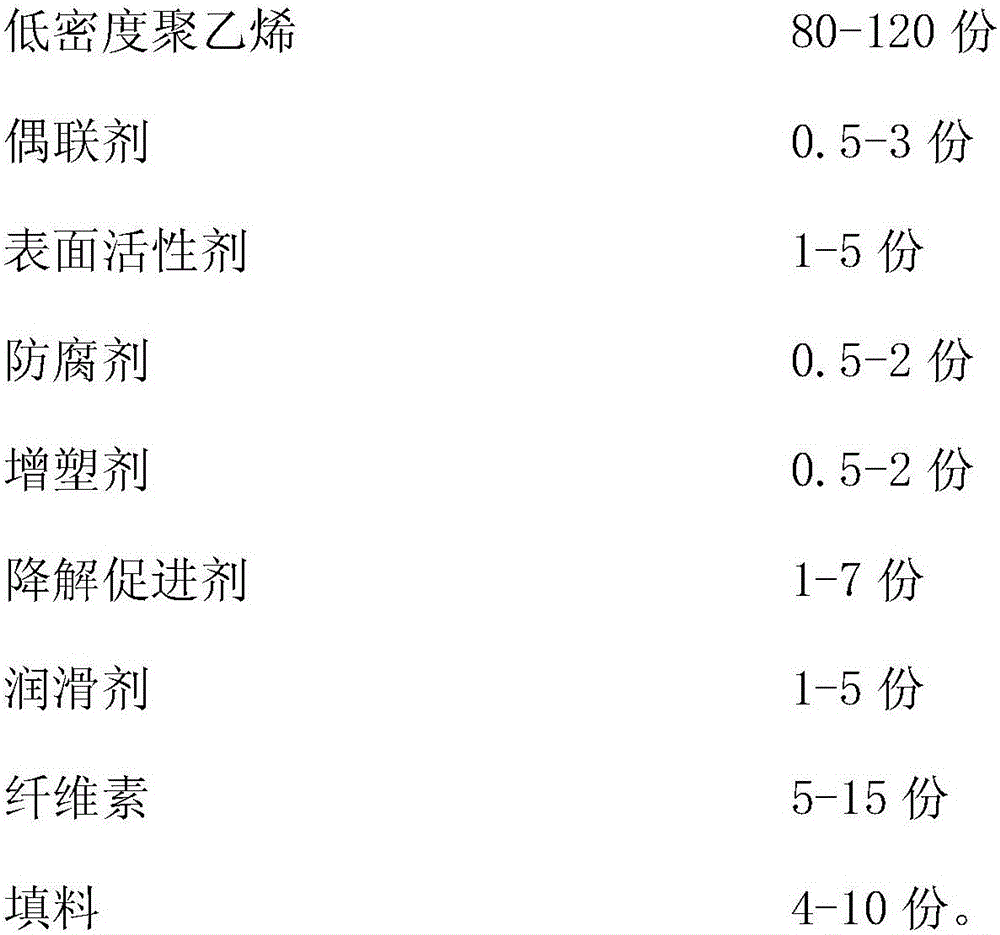

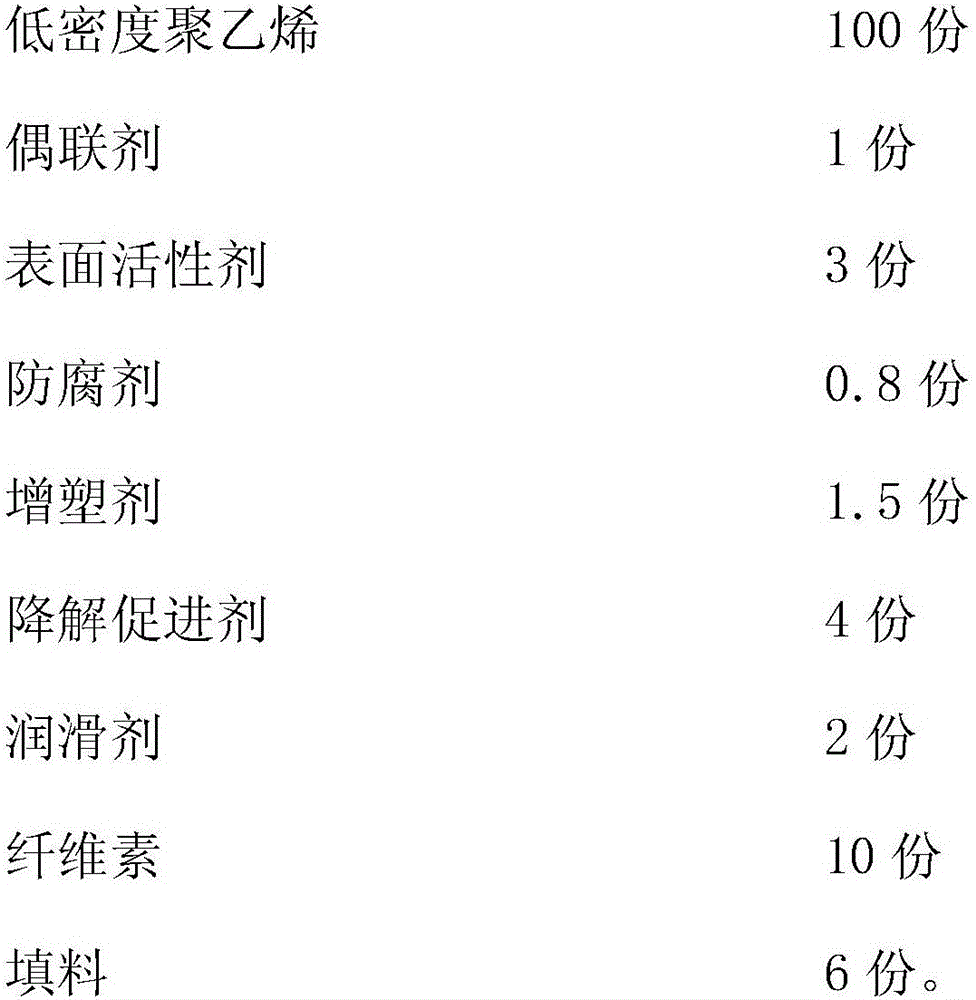

[0021] A wear-resistant plastic bag, consisting of the following raw materials in parts by weight: 100 parts of low-density polyethylene, 1 part of coupling agent, 3 parts of surfactant, 0.8 parts of preservative, 1.5 parts of plasticizer, and 4 parts of degradation accelerator , 2 parts of lubricant, 10 parts of cellulose, 6 parts of filler; wherein the preservative is nitrite, the plasticizer is triethyl citrate, and the degradation accelerator is 2,2-bis(4-hydroxyphenyl)propane , the filler is wollastonite.

[0022] A processing technology for a wear-resistant plastic bag, specifically comprising the following steps:

[0023] Adjust the heating temperature of the high mixer to 120°C, and the rotation speed is 500r / min, then add the corresponding weight parts of low-density polyethylene, cellulose, filler, coupling agent, and lubricant into the high mixer, and mix and stir for 20 minutes to obtain Premix, then add surfactants, preservatives, plasticizers, and degradation ac...

Embodiment 2

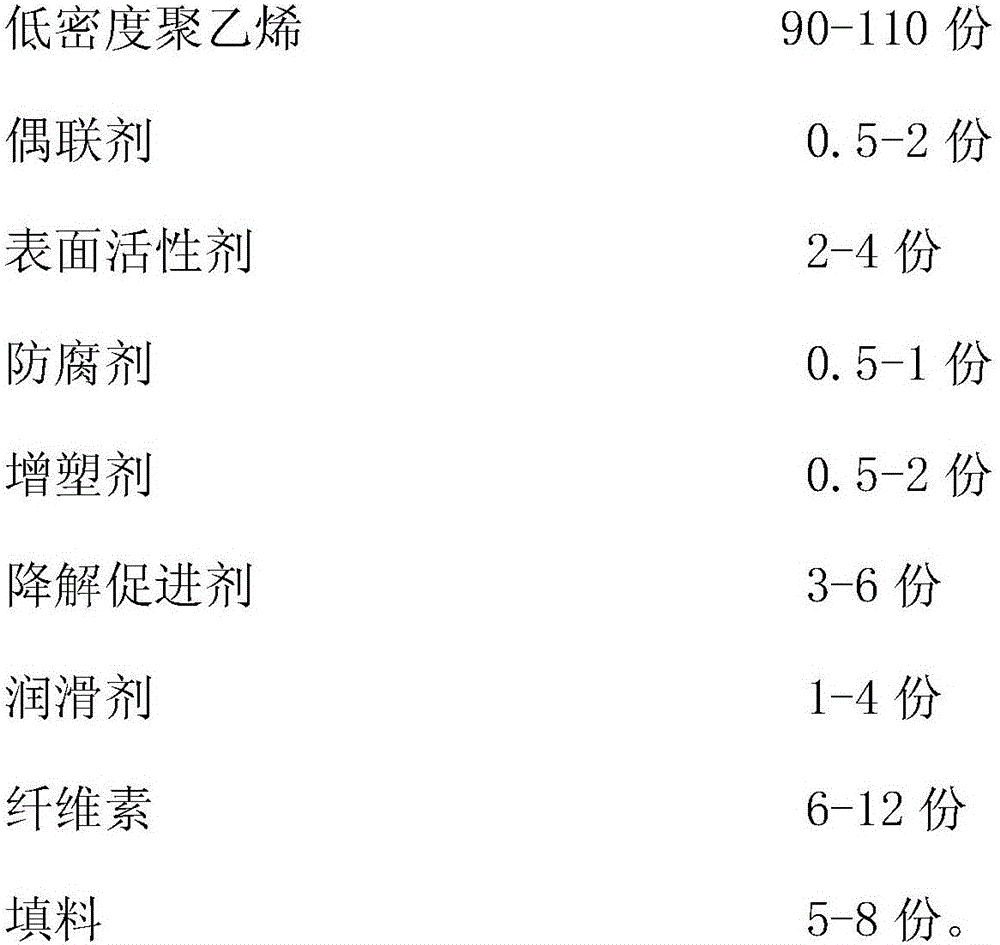

[0025] A wear-resistant plastic bag, consisting of the following raw materials in parts by weight: 80 parts of low-density polyethylene, 0.5 part of coupling agent, 1 part of surfactant, 0.5 part of preservative, 0.5 part of plasticizer, and 1 part of degradation accelerator , 1 part of lubricant, 5 parts of cellulose, and 4 parts of filler; wherein the preservative is nitrite, the plasticizer is dibutyl phthalate, and the degradation accelerator is 2,2-bis(4-hydroxyphenyl ) propane, and the filler is talcum powder.

[0026] A processing technology for a wear-resistant plastic bag, specifically comprising the following steps:

[0027] Adjust the heating temperature of the high mixer to 120°C, and the rotation speed is 500r / min, then add the corresponding weight parts of low-density polyethylene, cellulose, filler, coupling agent, and lubricant into the high mixer, and mix and stir for 15 minutes to obtain Premix, then add surfactants, preservatives, plasticizers, and degradat...

Embodiment 3

[0029] A wear-resistant plastic bag, consisting of the following raw materials in parts by weight: 120 parts of low-density polyethylene, 3 parts of coupling agent, 5 parts of surfactant, 2 parts of preservative, 2 parts of plasticizer, and 2 parts of degradation accelerator , 5 parts of lubricant, 15 parts of cellulose, and 10 parts of filler; wherein the preservative is nitrite, the plasticizer is triethyl citrate, and the degradation accelerator is 2,2-bis(4-hydroxyphenyl)propane , the filler is quartz powder.

[0030] A processing technology for a wear-resistant plastic bag, specifically comprising the following steps:

[0031] Adjust the heating temperature of the high mixer to 120°C, and the rotation speed is 500r / min, then add the corresponding weight parts of low-density polyethylene, cellulose, filler, coupling agent, and lubricant into the high mixer, and mix and stir for 30 minutes to obtain Premix, then add surfactants, preservatives, plasticizers, and degradation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com