Textile material and preparation method thereof

A textile and raw material technology, applied in the field of textile materials and their preparation, can solve problems such as poor mechanical properties of textile materials, achieve the effects of solving poor mechanical properties, stable dimensions, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

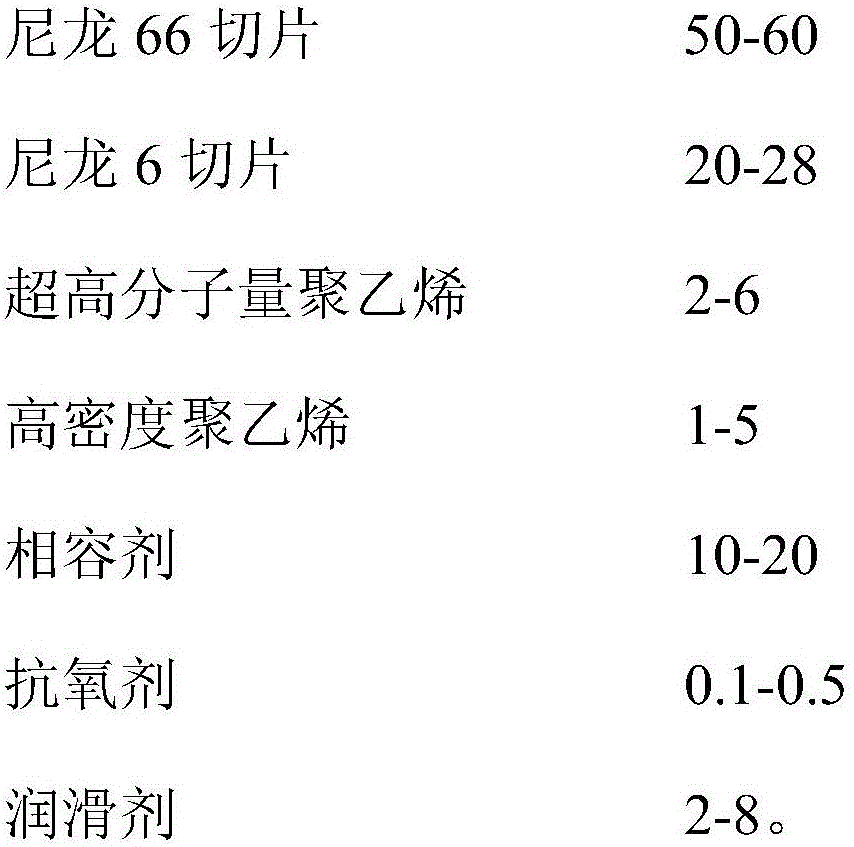

[0035] A kind of nylon 66 that can be used for weaving non-glass fiber shuttle, it is mainly prepared by following raw material by weight part:

[0036]

[0037] The relative viscosity of the nylon 66 chips is 2.5.

[0038] The compatibilizer is polyethylene grafted maleic anhydride.

[0039] The antioxidant is compounded of hindered phenolic antioxidant and phosphite antioxidant.

[0040] The hindered phenolic antioxidant is 1010; the phospholipid antioxidant is 168.

[0041] Lubricants are metal stearate soaps.

[0042] Described metal stearate soap is barium stearate or calcium stearate or zinc stearate.

[0043] Can be used for the preparation method described method of the nylon 66 of weaving non-glass fiber shuttle as described above comprises the following steps:

[0044] Mix the raw materials in the formula amount for 1-5 minutes in a high-speed mixer, and then add them to a twin-screw extruder at a processing temperature of 200-300°C and a screw speed of 200-36...

Embodiment 2

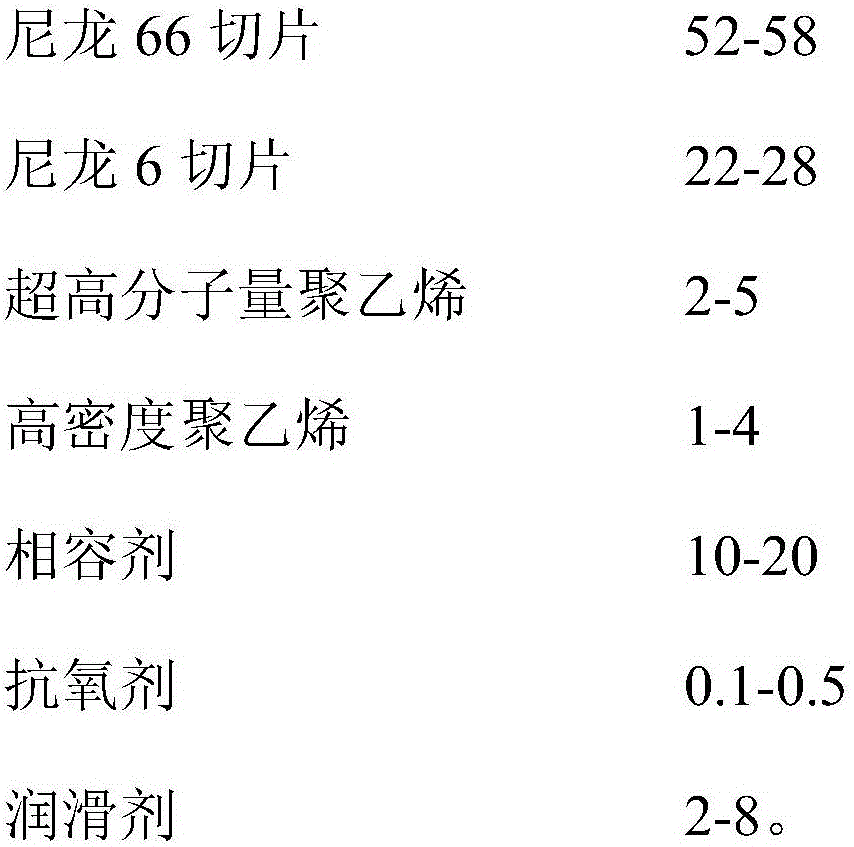

[0046] A kind of nylon 66 that can be used for weaving non-glass fiber shuttle, it is mainly prepared by following raw material by weight part:

[0047]

[0048]

[0049] The relative viscosity of the nylon 66 chips is 2.5-2.7.

[0050] The compatibilizer is polyethylene grafted maleic anhydride.

[0051] The antioxidant is compounded of hindered phenolic antioxidant and phosphite antioxidant.

[0052] The hindered phenolic antioxidant is 1010 or 1098; the phospholipid antioxidant is 168.

[0053] Lubricants are metal stearate soaps or fatty acid amides.

[0054] The metal stearate soaps are barium stearate, calcium stearate or zinc stearate, and the fatty acid amides are TAF or EBS.

[0055] Can be used for the preparation method described method of the nylon 66 of weaving non-glass fiber shuttle as described above comprises the following steps:

[0056] Mix the raw materials in the formula amount for 1-5 minutes in a high-speed mixer, and then add them to a twin-sc...

Embodiment 3

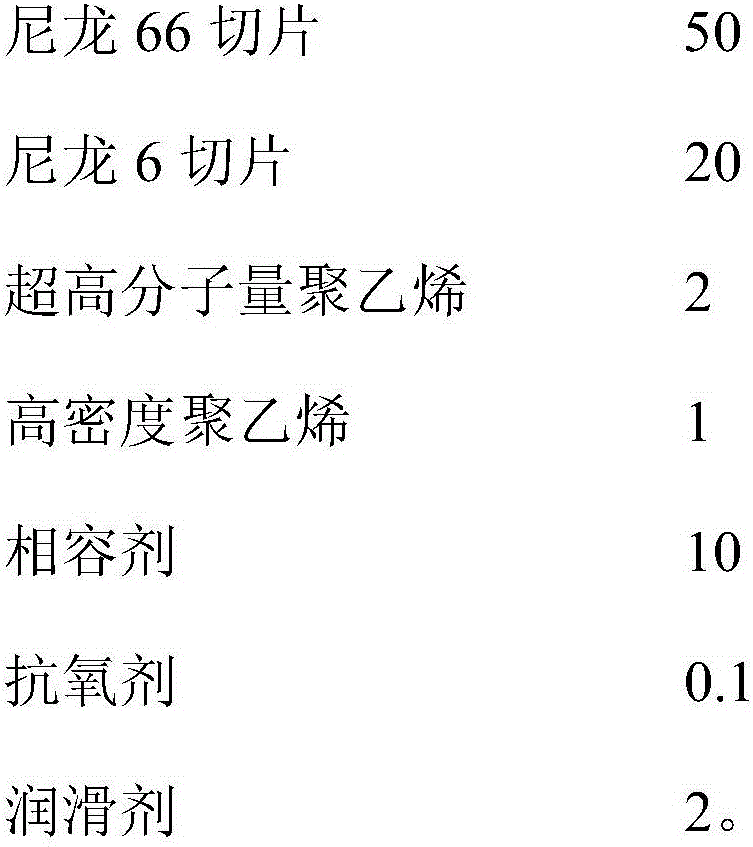

[0058] A kind of nylon 66 that can be used for weaving non-glass fiber shuttle, it is mainly prepared by following raw material by weight part:

[0059]

[0060]

[0061] The relative viscosity of the nylon 66 chips is 2.5-2.7.

[0062] The compatibilizer is polyethylene grafted maleic anhydride.

[0063] The antioxidant is compounded of hindered phenolic antioxidant and phosphite antioxidant.

[0064] The hindered phenolic antioxidant is 1010 or 1098; the phospholipid antioxidant is 168.

[0065] Lubricants are metal stearate soaps or fatty acid amides.

[0066] The metal stearate soaps are barium stearate, calcium stearate or zinc stearate, and the fatty acid amides are TAF or EBS.

[0067] Can be used for the preparation method described method of the nylon 66 of weaving non-glass fiber shuttle as described above comprises the following steps:

[0068] Mix the raw materials of the formulated amount in a high-speed mixer for 1-5 minutes, and then add them to a twin-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com