Method for simultaneously producing vitamin K2 and nattokinase through Bacillus natto fermentation

A technology of Bacillus natto and nattokinase, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of high cost and low yield, and achieve the improvement of co-production rate and low fermentation cost , Conducive to the effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

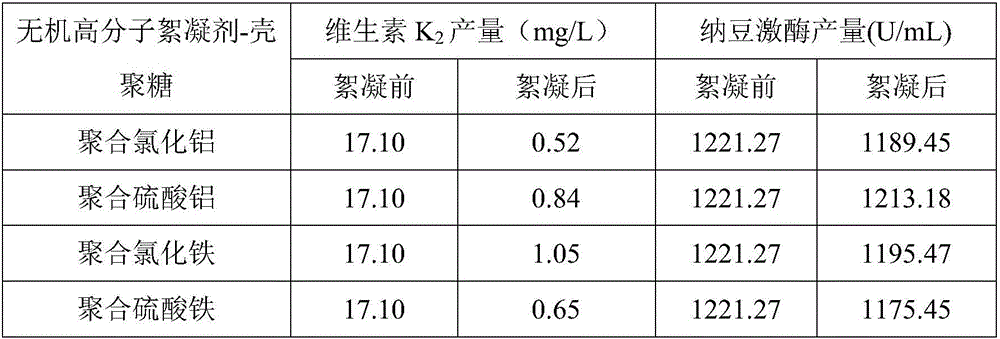

Embodiment 1

[0027] A method of co-producing vitamin K by fermentation of Bacillus natto 2 and nattokinase method, using Bacillus natto as a fermentation strain, optimizing the medium formulation, including strain activation, preparing seeds, inoculating fermentation medium, controlling the growth of Bacillus natto and the metabolite vitamin K in the fermentation process 2 and nattokinase production, the vitamin K in the fermentation broth 2 Separated from nattokinase.

[0028] Include the following steps:

[0029] (1) Strain activation: Streak Bacillus natto onto plate medium (recipe: peptone 5g / L, beef extract 5g / L, sodium chloride 3g / L, agar powder 20g / L, sterilized at 121°C 20min, place it at 30°C for cultivation, and then take a single colony and streak it to the test tube culture medium (the formula is: peptone 5g / L, beef extract 5g / L, sodium chloride 3g / L, agar powder 20g / L, Sterilized at 121°C for 20 minutes, placed at 30°C for use) for cultivation, wherein the culture condition...

Embodiment 2

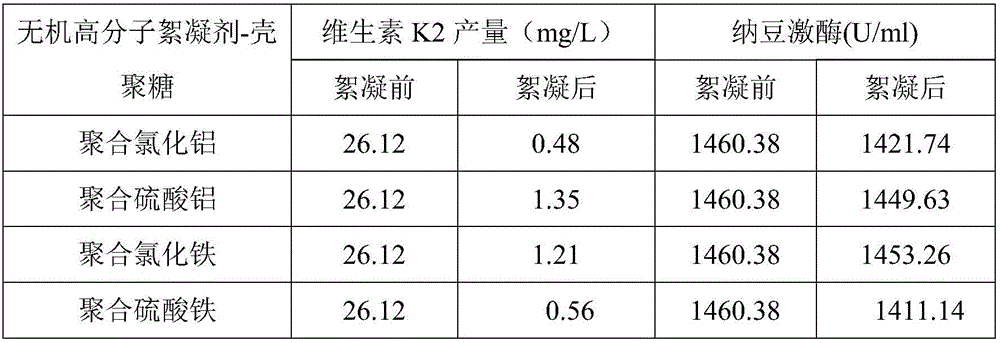

[0040] A method of co-producing vitamin K by fermentation of Bacillus natto 2 and nattokinase method, using Bacillus natto as a fermentation strain, optimizing the medium formulation, including strain activation, preparing seeds, inoculating fermentation medium, controlling the growth of Bacillus natto and the metabolite vitamin K in the fermentation process 2 and nattokinase production, the vitamin K in the fermentation broth 2 Separated from nattokinase.

[0041] Include the following steps:

[0042] (1) Strain activation: Streak Bacillus natto onto plate medium (formulation: peptone 5-7g / L, beef extract 7g / L, sodium chloride 4g / L, agar powder 20g / L, 121°C Sterilize for 20 minutes, place it at 40°C for cultivation, and then take a single colony and streak it to the test tube medium (the formula is: peptone 7g / L, beef extract 7g / L, sodium chloride 4g / L, agar powder 20g / L L, sterilized at 121° C. for 20 minutes, placed at 40° C. for use) for cultivation, wherein the culture...

Embodiment 3

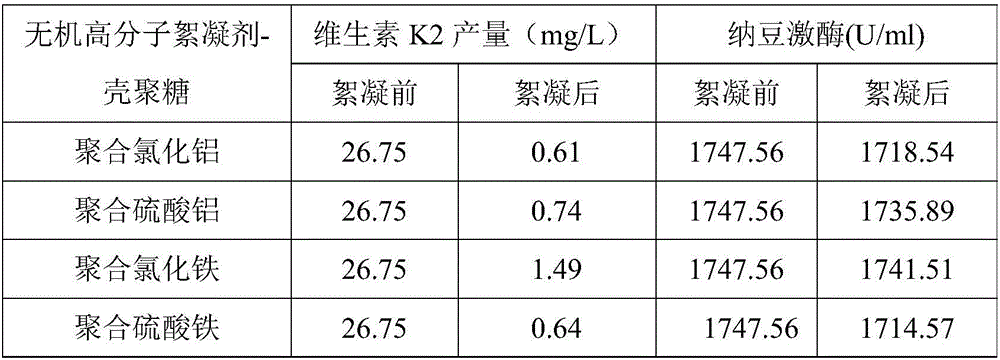

[0053] A method of co-producing vitamin K by fermentation of Bacillus natto 2 and nattokinase method, using Bacillus natto as a fermentation strain, optimizing the medium formulation, including strain activation, preparing seeds, inoculating fermentation medium, controlling the growth of Bacillus natto and the metabolite vitamin K in the fermentation process 2 and nattokinase production, the vitamin K in the fermentation broth 2 Separated from nattokinase.

[0054] Include the following steps:

[0055] (1) Strain activation: Streak Bacillus natto onto the plate medium (the formula is: peptone 6g / L, beef extract 6g / L, sodium chloride 3.5g / L, agar powder 20g / L, sterilized at 121°C Bacteria for 20 minutes, placed in 35 ° C for use), and then took a single colony and streaked it to the test tube medium (formulation: peptone 6g / L, beef extract 6g / L, sodium chloride 3.5g / L, agar powder 20g / L L, sterilized at 121° C. for 20 minutes, placed at 35° C. for use) for cultivation, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com