Protective method for public fuel gas pipeline above ground

A gas pipeline and public technology, applied in pipeline anticorrosion/rust protection, pipeline protection, pipeline damage/wear prevention, etc., can solve fire or explosion accidents, economic losses, threats to public safety, etc., to reduce maintenance or replacement frequency, reduce economic losses, and reduce safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

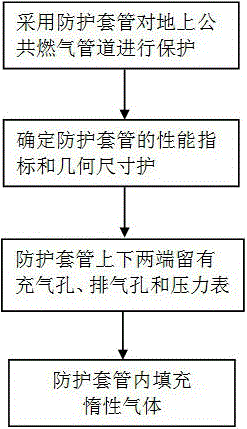

[0019] Such as figure 1 As shown, the present invention provides a method for protecting public gas pipelines on the ground, and the method for protecting comprises:

[0020] Step 1: Protect the above-ground public gas pipeline with a protective sleeve;

[0021] Step 2: Determine the performance index and geometric dimensions of the protective sleeve;

[0022] Step 3: Install air-filling holes, exhaust holes and pressure gauges at the upper and lower ends of the protective casing;

[0023] Step 4: Fill the protective casing with inert gas;

[0024] Wherein, the above-ground public gas pipeline protection method includes the protection of the above-ground public gas pipeline with a protective sleeve, the determination of the performance index and geometric dimensions of the protective sleeve, the setting of air-filling holes at the upper and lower ends of the protective sleeve, and exhaust gas. Hole and pressure gauge, the protective casing is filled with inert gas.

[0025...

Embodiment 2

[0036] 1. Geographic location: Southwest China

[0037] 2. Environmental conditions: Subtropical monsoon humid climate, annual average temperature 18.5°C, annual average relative humidity 70%, maximum relative humidity 87%, average frequency of acid rain 4.58 / 54.5%, annual average deposition rate of sulfur dioxide 45 (mg / (m 2 • d), chloride ion CI - The annual average settlement rate is 7.9 (mg / (m 2 • d).

[0038] 3. Calculation of corrosion rate of steel in the first year of carbon steel:

[0039] r corr =1.77Pd 0.52 EXP(0.020RH+Fst)+0.102Sd 0.62 EXP(0.033RH+0.040t) Formula 1

[0040] The corrosion rate calculated according to formula 1 is 62.53μm / a

[0041] 4. Use protective sleeves to protect the above-ground public gas pipelines, and choose PVC material as the protective sleeves. PVC has excellent corrosion resistance, and its service life at room temperature is not less than 50 years. It has the characteristics of low price and simple construction and maintenance. ...

Embodiment 3

[0047] 1. Geographic location: Southern coastal area

[0048] 2. Environmental conditions: subtropical marine atmosphere environment, annual average temperature 22.4 ℃, annual average relative humidity 77%, maximum relative humidity 82%, annual average deposition rate of sulfur dioxide 10 (mg / (m 2 • d), chloride ion CI - The annual average sedimentation rate is 62.6 (mg / (m 2 • d).

[0049] 3. Corrosion rate of steel in the first year of carbon steel:

[0050] r corr =1.77Pd 0.52 EXP(0.020RH+Fst)+0.102Sd 0.62EXP(0.033RH+0.040t) Formula 1

[0051] The corrosion rate calculated according to formula 1 is 64.87μm / a

[0052] 4. Use protective sleeves to protect the public gas pipelines on the ground, and choose PVC material as the protective sleeves.

[0053] 5. The geometric size of the protective casing corresponding to the gas pipeline is 90mm of DN50 casing.

[0054] 6. After the installation of the protective casing is completed, fill the nitrogen gas from the inflatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com