High-quantum-yield electrochemiluminescence gold nano-cluster probe and preparation method of high-quantum-yield electrochemiluminescence gold nano-cluster probe

A technology of gold nanoclusters and electrochemistry, applied in the field of nanometers, to achieve the effects of high luminous intensity, good biocompatibility and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

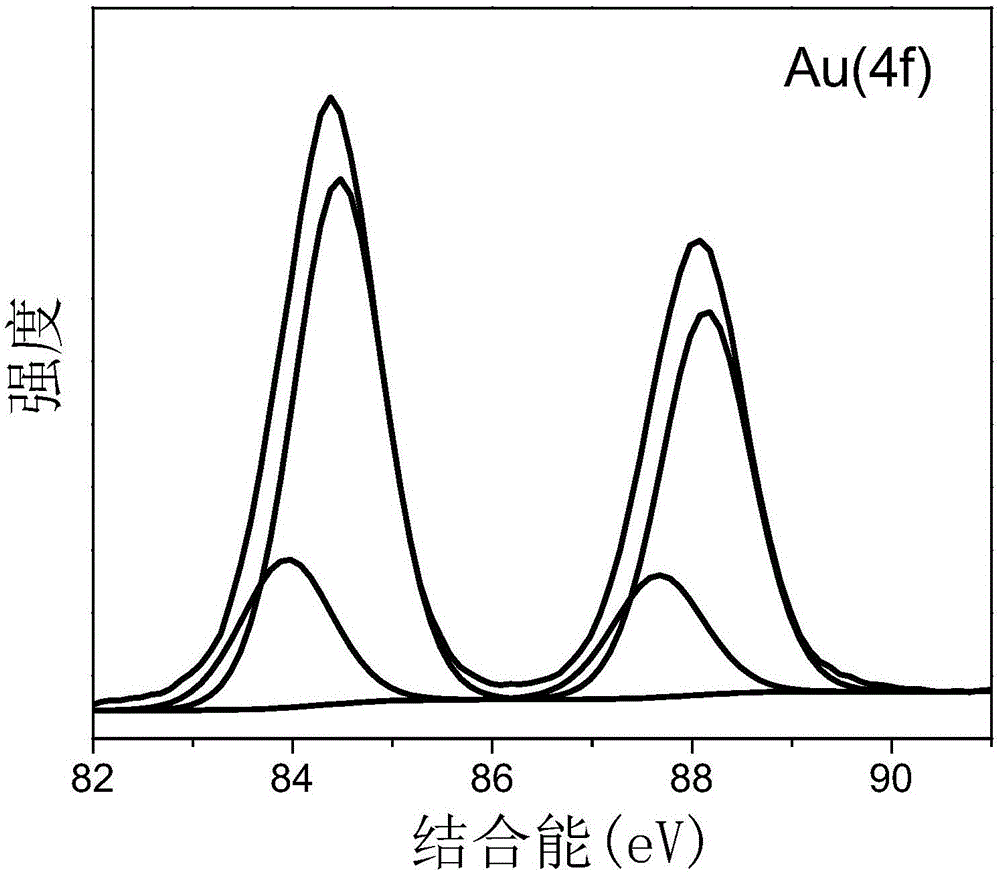

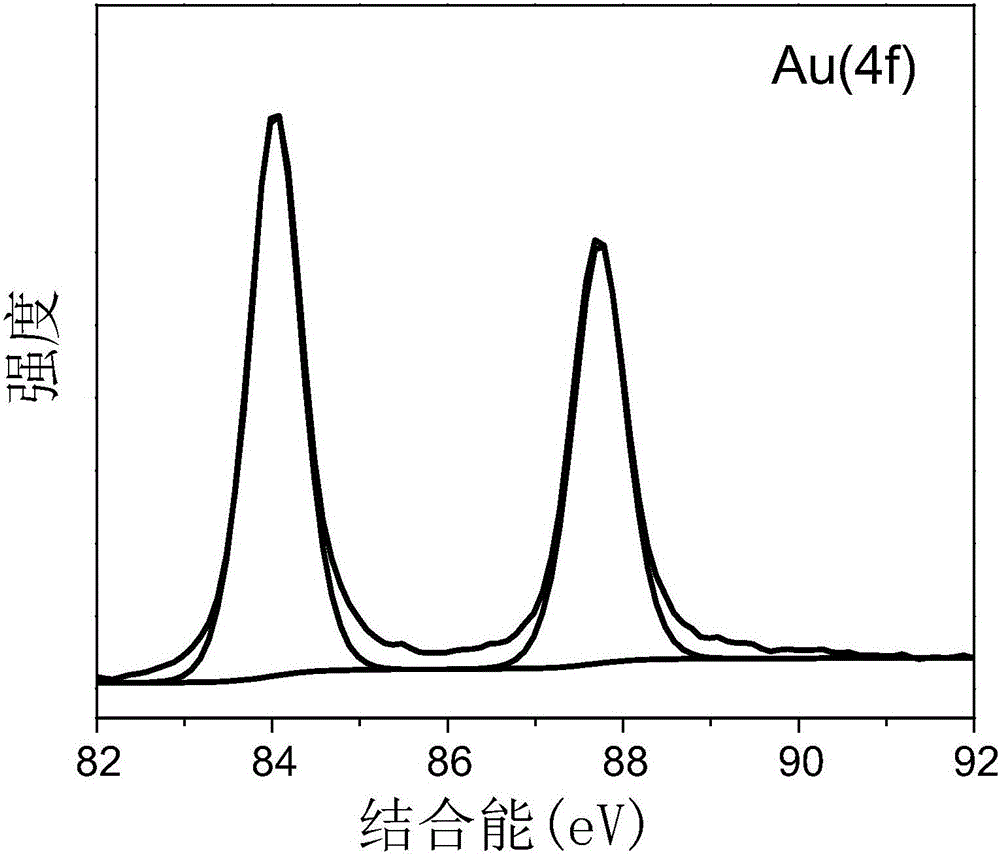

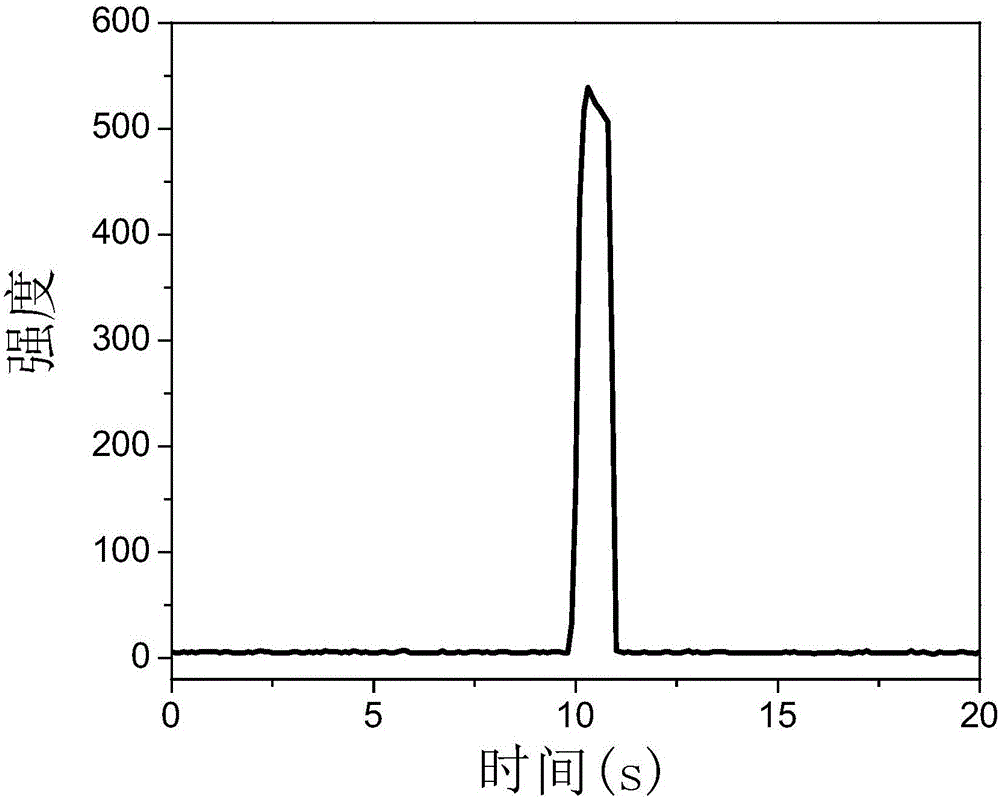

Embodiment 1

[0039]Add 0.6 mL of 0.5 mol / L sodium hydroxide and 0.4 mL of 20 mg / mL chloroauric acid solution to 4 mL of 0.08 mol / L N-acetyl-L-cysteine solution, mix After uniformity, they were placed in a 37°C constant temperature water tank and incubated for 3 hours. After the reaction, the reaction solution was purified by dialysis using a dialysis bag with a molecular cutoff of 3500 to obtain an aqueous solution of N-acetyl-L-cysteine-gold nanoclusters. Glassy carbon electrodes with a diameter of 3 mm were coated with 1.0 μm, 0.3 μm and 0.05 μm Al 2 o 3 The powder is polished and polished in turn until it reaches a smooth mirror surface, and then put in HNO in turn 3 Solution (volume ratio of concentrated nitric acid to water is 1:1), absolute ethanol, ultrasonic cleaning in deionized water for 3 minutes, and blow dry with nitrogen gas. Take 5 μL of N-acetyl-L-cysteine-protected gold nanocluster solution and drop it on the surface of the treated glassy carbon electrode, and dry it ...

Embodiment 2

[0041] Add 0.6 mL of 0.5 mol / L sodium hydroxide and 0.4 mL of 20 mg / mL chloroauric acid solution to 4 mL of 0.08 mol / L N-acetyl-L-cysteine solution, mix After uniformity, they were placed in a 37°C constant temperature water tank and incubated for 3 hours. After the reaction, the reaction solution was purified by dialysis using a dialysis bag with a molecular cutoff of 3500 to obtain an aqueous solution of N-acetyl-L-cysteine-gold nanoclusters. Glassy carbon electrodes with a diameter of 3 mm were coated with 1.0 μm, 0.3 μm and 0.05 μm Al 2 o 3 The powder is polished and polished in turn until it reaches a smooth mirror surface, and then put in HNO in turn 3 Solution (volume ratio of concentrated nitric acid to water is 1:1), absolute ethanol, ultrasonic cleaning in deionized water for 3 minutes, and blow dry with nitrogen gas. Take 5 μL of N-acetyl-L-cysteine-protected gold nanocluster solution and drop it on the surface of the treated glassy carbon electrode, and dry it...

Embodiment 3

[0043] Add 0.6 mL of 0.5 mol / L sodium hydroxide and 0.4 mL of 20 mg / mL chloroauric acid solution to 4 mL of 0.08 mol / L N-acetyl-L-cysteine solution, mix After uniformity, they were placed in a 37°C constant temperature water tank and incubated for 3 hours. After the reaction, the reaction solution was purified by dialysis using a dialysis bag with a molecular cutoff of 3500 to obtain an aqueous solution of N-acetyl-L-cysteine-gold nanoclusters. Glassy carbon electrodes with a diameter of 3 mm were coated with 1.0 μm, 0.3 μm and 0.05 μm Al 2 o 3 The powder is polished and polished in turn until it reaches a smooth mirror surface, and then put in HNO in turn 3 Solution (volume ratio of concentrated nitric acid to water is 1:1), absolute ethanol, ultrasonic cleaning in deionized water for 3 minutes, and blow dry with nitrogen gas. Take 5 μL of N-acetyl-L-cysteine-protected gold nanocluster solution and drop it on the surface of the treated glassy carbon electrode, and dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com