Method for preparing digestible starch with resistance improved

A technology that is easy to digest and starch is applied in the field of starch processing to achieve the effect of increasing resistant starch and increasing its content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

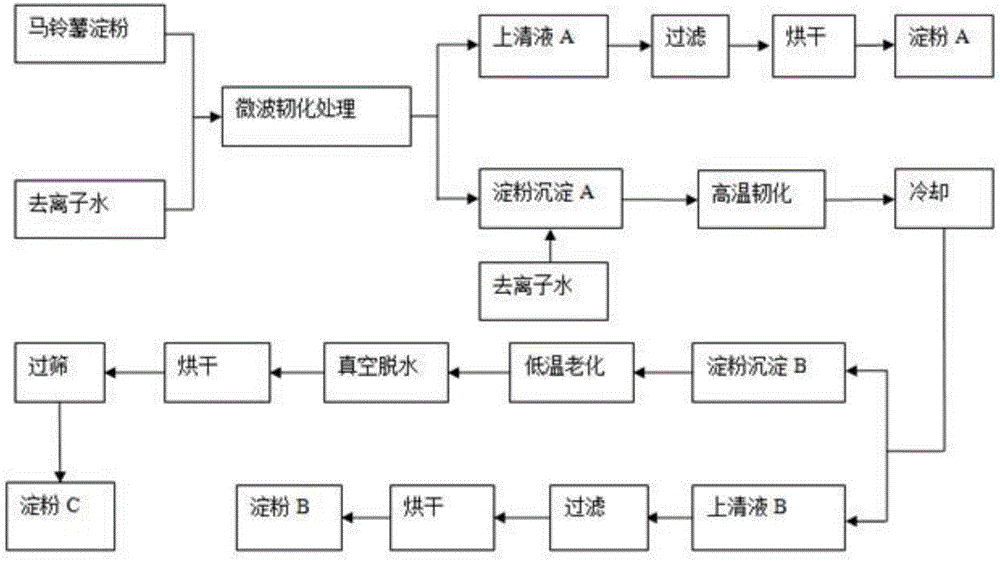

[0038] The technological process of the method for preparing starch with increasing resistance and digestibility by using microwave and toughening treatment method of the present invention is shown in the appendix figure 1 .

[0039] Concrete process steps are as follows:

[0040] The method for preparing resistant and / or digestible starch comprises the following steps:

[0041] (1) Deionized water is added to the potato starch to form a potato starch emulsion; the mass-to-volume ratio of potatoes and deionized water is: 1:2;

[0042] (2) Stir the potato starch milk in step (1) evenly, microwave toughening treatment, take out after microwave treatment and let stand for 6-7 hours, separate to obtain supernatant A and starch precipitation A;

[0043] The conditions of microwave treatment are: power 300W, treatment time 100s, microwave temperature 37°C;

[0044] (3) Add deionized water to the starch precipitation A, place it in a constant temperature shaking incubator for high...

Embodiment 2

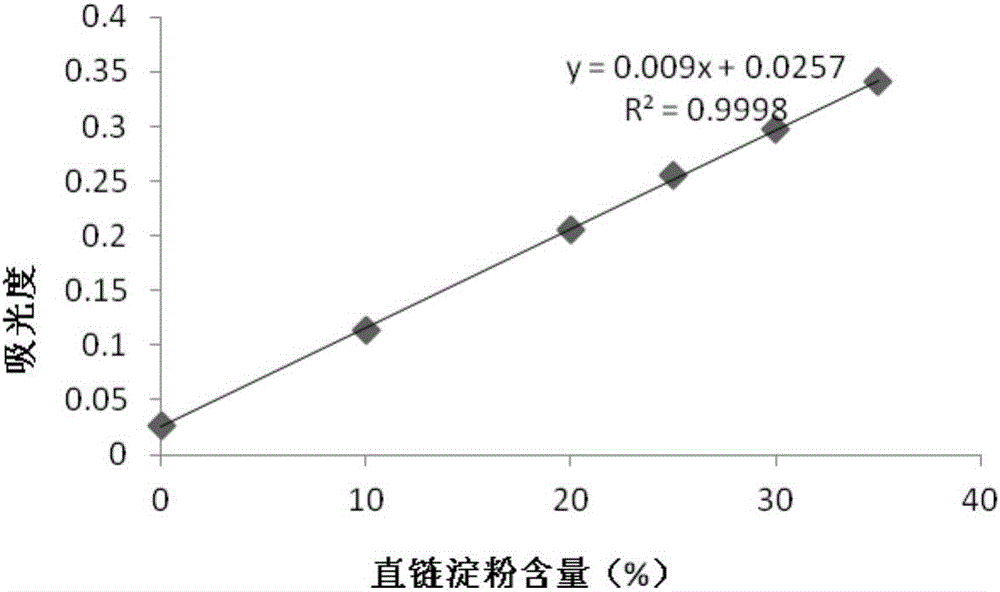

[0058] The resistant starch content of starch C was determined. First, draw a glucose standard curve, as shown in Table 1:

[0059] Table 1 Glucose standard curve drawing table

[0060]

[0061]

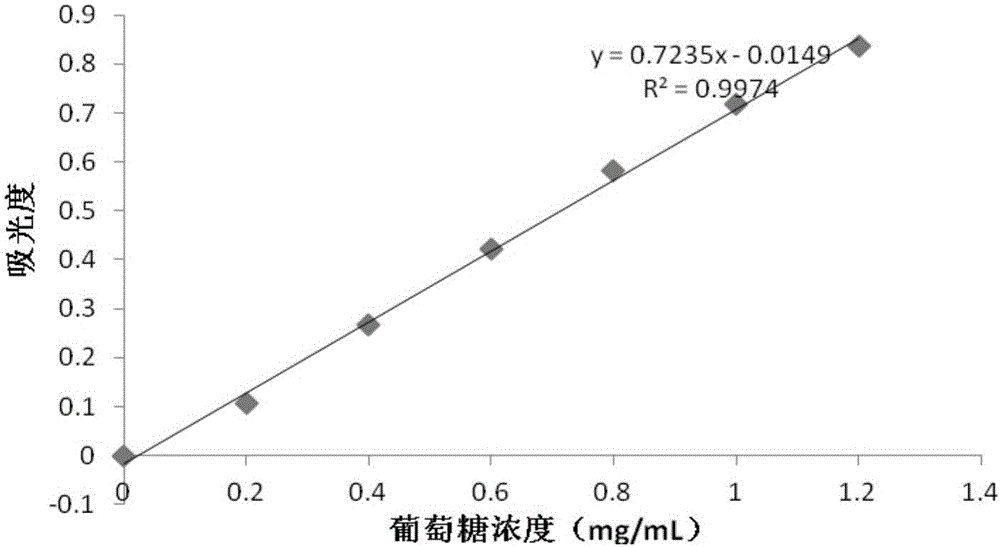

[0062] As shown in Table 1, shake each stoppered test tube well and place it in a boiling water bath to heat accurately for 5 minutes, take it out, cool it down to room temperature, dilute it to 25 mL with distilled water, mix well, measure the absorbance at 540 nm, and take the number of mg of glucose as the abscissa , the absorbance is the ordinate, draw the glucose standard curve. as follows figure 2 Shown:

[0063] (2) Hydrolysis of non-resistant starch

[0064] Accurately weigh 100±5mg of starch C (dry basis) into a centrifuge tube, add 4mL of a mixture of pancreatic α-amylase (30U / mL) and amyloglucosidase (3U / mL), and mix well. At 37°C, the shaking speed was 200 beats / min, and the reaction was performed at a constant temperature for 16 hours. After shaking, take ou...

Embodiment 3

[0075] The present invention measures the digestibility of the obtained starch AB mixture and starch C. Accurately weigh 100mg of maltose in a 100mL volumetric flask, constant volume, and accurately draw 1, 2, 3, 4, 6, and 10mL of standard maltose solutions into a 100mL volumetric flask, then you can get 10μg / mL, 20μg / mL, 30μg / mL , 40μg / mL, 60μg / mL, 100μg / mL maltose standard solution. Take 2mL of standard maltose solution in a test tube, add 1mL of 5% phenol solution, shake well, add 5mL of concentrated sulfuric acid, and place in a 30°C water bath for 20min. Take the blank as a reference, measure at a wavelength of 490nm, take the absorbance as the abscissa, and the standard maltose concentration as the ordinate, and draw a standard curve.

[0076] Accurately weigh 100mg of starch A and 400mg of starch B in the dialysis bag, and then accurately weigh 500mg of starch C in the dialysis bag. The raw materials in the two dialysis bags are subjected to the following experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com