Safe non-toxic mosquito repellent lotion and preparation method thereof

A safe, non-toxic, mosquito repellent technology, applied in the field of daily chemicals, can solve the problems of low purity, low efficiency, and poor mosquito repellent durability of functional ingredients, and achieve long-lasting mosquito repellent effect, high efficiency, and time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

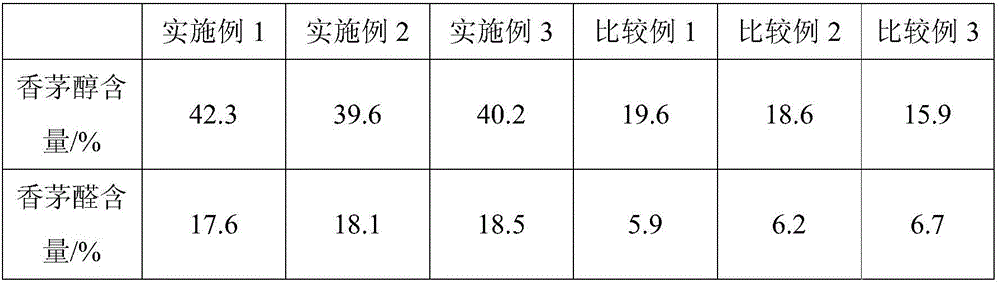

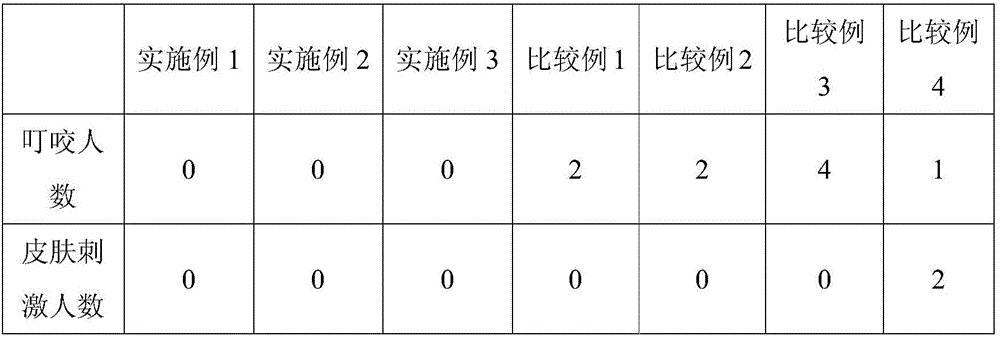

Examples

Embodiment 1

[0025] (1) Wash 100g of high-quality citronella grass, dry it in the sun, and then pulverize it to obtain citronella grass powder, add 1500g of deionized water, use 10g of cellulase, 30g of carboxylesterase and 10g of pectinase at 60°C, pH5, Enzymolysis for 6 hours;

[0026] (2) heating 1650g of enzymolysis solution gained in step (1) to boiling, incubating for 8 minutes to kill the enzyme, then cooling to room temperature, and centrifuging to obtain 130g of citronella clear liquid;

[0027] (3) Pour the citronella grass clear night obtained in step (2) into 1100g carbon tetrachloride, after ultrasonication for 8 minutes, let it stand for stratification, take the supernatant, separate through the oil-water separation tower, and the oil phase is 26.8g, which is the fragrance Thatched grass extract, the oil-water separation temperature is 50°C;

[0028] (4) Dissolve 3g natural borneol, 2g essence and 1g salicylic acid in 5g ethanol, then add 20g citronella extract, 6g butanedio...

Embodiment 2

[0030] (1) Wash 100g of high-quality citronella grass, dry it in the sun, and then pulverize it to obtain citronella grass powder, add 1800g of deionized water, use 7g of cellulase, 21g of carboxylesterase and 7g of pectinase at 50°C and PH4, Enzymolysis for 7 hours;

[0031] (2) 1650g of the enzymatic hydrolyzate obtained in step (1) was heated to boiling, incubated for 5 minutes to kill the enzyme, then cooled to room temperature, and centrifuged to obtain 142g of citronella clear liquid;

[0032] (3) Pour the citronella grass clear night obtained in step (2) into 1150g carbon tetrachloride, after ultrasonication for 5 minutes, let it stand for stratification, take the supernatant, separate through the oil-water separation tower, and the oil phase is 30.2g, which is the fragrance Thatched grass extract, the oil-water separation temperature is 45°C;

[0033] (4) 2g natural borneol, 3g essence and 2g salicylic acid are dissolved in 6g ethanol, then add 18g citronella extract,...

Embodiment 3

[0035] (1) Wash 100g of high-quality citronella grass, dry it in the sun, and then pulverize it to obtain citronella grass powder, add 2000g of deionized water, use 4g of cellulase, 12g of carboxylesterase and 4g of pectinase at 65°C and PH6, Enzymolysis for 5 hours;

[0036] (2) heating the enzymolysis solution obtained in step (1) to boiling, incubating for 10 minutes to kill the enzyme, then cooling to room temperature, and centrifuging to obtain 110 g of citronella clear liquid;

[0037] (3) Pour the citronella grass clear night obtained in step (2) into 1100g of carbon tetrachloride, after ultrasonication for 10 minutes, let it stand for stratification, take the supernatant, separate through the oil-water separation tower, and the oil phase is 28.1g, which is the fragrance Thatched grass extract, the oil-water separation temperature is 55°C;

[0038] (4) Dissolve 4g natural borneol, 1g essence and 3g salicylic acid in 8g ethanol, then add 15g citronella extract, 8g triet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com