Water-soluble nanometer sustained-release functional coenzyme Q10 micro-capsule, method for preparing same and application of water-soluble nanometer sustained-release functional coenzyme Q10 micro-capsule

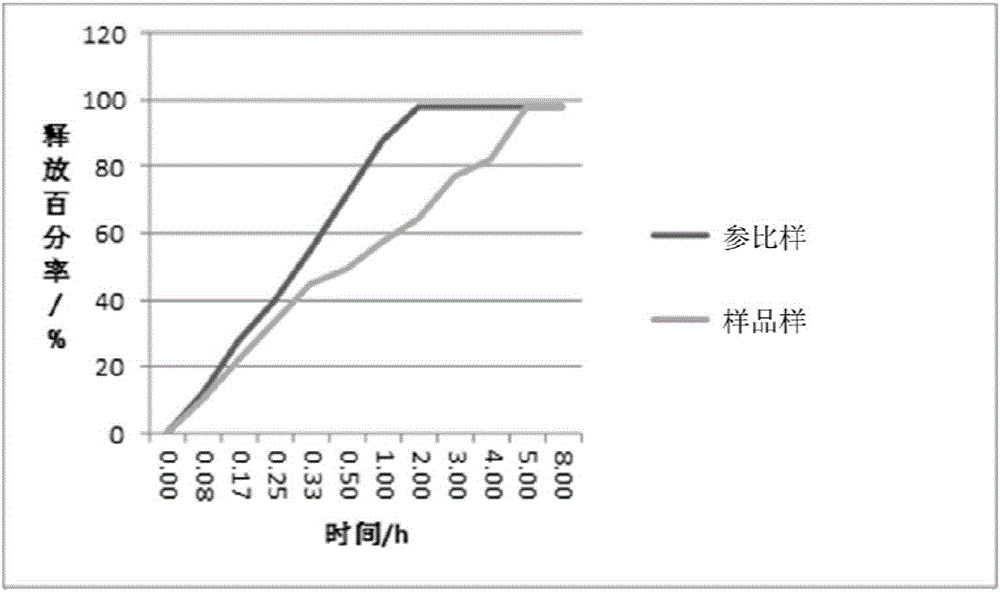

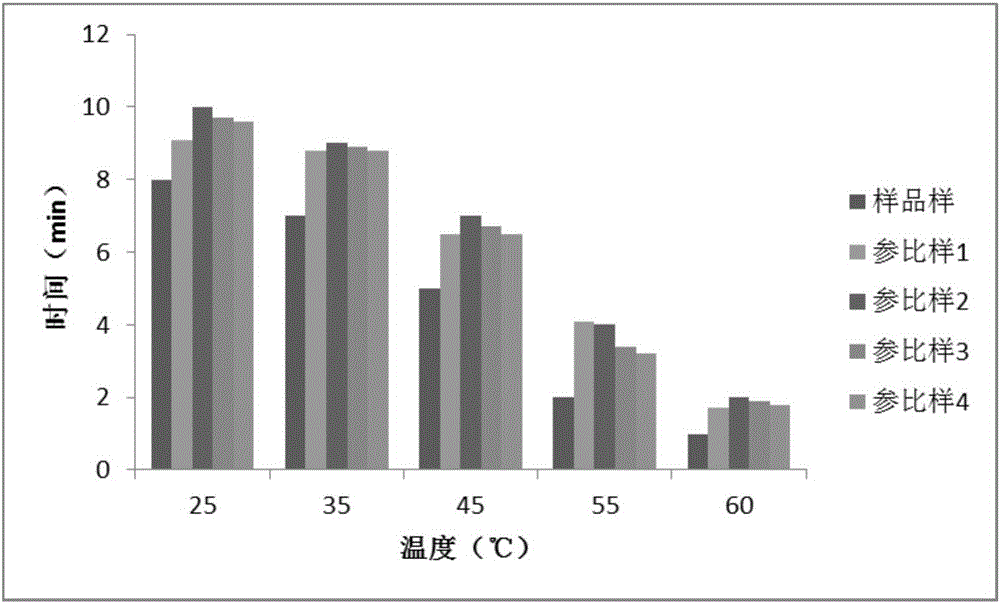

A nano-sustained-release and functional technology, applied in the field of preparation of coenzyme Q10 microcapsules, can solve the problems of poor water solubility, low bioavailability and instability, and achieve the effects of complete release, good stability and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The 240Kg coenzyme Q10 crystals were ground together with 16Kg piperine, 40Kg lecithin, 40Kg natural VE, and 654Kg soybean oil in a nanomill at a temperature of 25° C. to a crystal particle size of 5 μm or less to obtain a coenzyme Q10 dispersion.

[0037] Dissolve 1000Kg of modified starch (T809) and 10Kg of sucrose ester (HLB value 13-16) in 3000Kg of water to prepare an aqueous solution of modified starch, and keep it at 40°C for later use.

[0038] The coenzyme Q10 dispersion is heated to 50°C, and after the coenzyme Q10 dispersion is completely dissolved, it is cooled to 40°C and kept warm for use.

[0039] The aforementioned Coenzyme Q10 dispersion was added to the modified starch aqueous solution, sheared at 10000 rpm for 30 minutes, and homogenized at 60 MPa for 3 times to obtain a nano-dispersed Coenzyme Q10 emulsion at the outlet.

[0040] The above-mentioned nano-dispersed coenzyme Q10 emulsion was spray-fluidized double-packed drying, and corn starch was used as the ...

Embodiment 2

[0042] Combine 20Kg of coenzyme Q10 crystals, 2Kg of piperine, 30Kg of lecithin, 4Kg of natural VE, 10Kg of monoglycerides, 1Kg of rosemary extract (containing 10% carnosic acid), and 498Kg of olive oil in a nanomill at a temperature of 20°C Down-grind to a crystal particle size of 5 μm or less to obtain a Coenzyme Q10 dispersion.

[0043] Dissolve 400Kg of modified starch (T809) and 35Kg of sucrose esters (HLB value 13-16) in 1500Kg of water to prepare a modified starch aqueous solution, and keep it at 45°C for later use.

[0044] The coenzyme Q10 dispersion is heated to 35°C, and after the coenzyme Q10 dispersion is completely dissolved, it is cooled to 30°C and kept warm for later use.

[0045] The aforementioned Coenzyme Q10 dispersion was added to the modified starch aqueous solution, sheared at 10000 rpm for 30 minutes, and homogenized at 80 MPa for 3 times, to obtain a nano-dispersed Coenzyme Q10 emulsion at the outlet.

[0046] The above-mentioned nano-dispersed coenzyme Q10 e...

Embodiment 3

[0048] The 400Kg coenzyme Q10 crystals were ground together with 20Kg piperine, 40Kg lecithin, 80Kg natural VE, 20Kg 2,6-di-tert-butyl-p-cresol, 60Kg sucrose acetate isobutyrate, and 880Kg isopropyl myristate. Grinding at a temperature of 15°C in the machine to a crystal particle size of 5 μm or less, to obtain a Coenzyme Q10 dispersion.

[0049] Dissolve 400Kg of modified gum arabic (A-2010) and 100Kg of poloxamer 188 in 2000Kg of water to prepare an aqueous solution of modified gum arabic and keep it at 35°C for later use.

[0050] The coenzyme Q10 dispersion is heated to 45°C, and after the coenzyme Q10 dispersion is completely dissolved, it is cooled to 35°C and kept warm for later use.

[0051] The aforementioned Coenzyme Q10 dispersion was added to the modified gum arabic aqueous solution, sheared for 30 minutes at 10000 rpm, and homogenized at 65 MPa for 3 times to obtain a nano-dispersed Coenzyme Q10 emulsion at the outlet.

[0052] The above-mentioned nano-dispersed coenzyme ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com