Antibacterial biological membrane and preparation method thereof

A biofilm and antimicrobial peptide technology, applied in the medical field, can solve the problems of unstable and easy-to-degrade antibacterial biofilms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

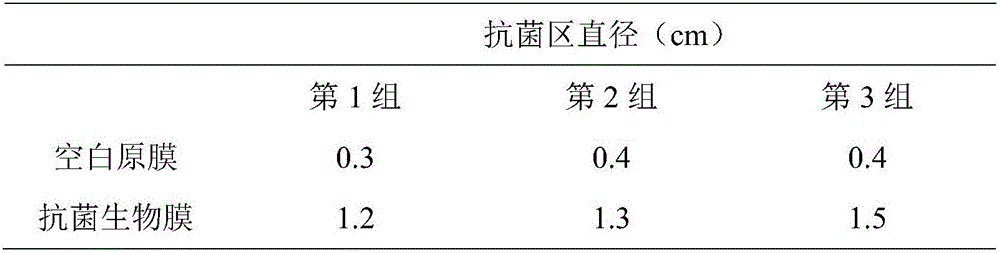

Embodiment 1

[0022] Get the concentrated solution of pectin obtained in the production of high methoxy pectin, make its pectin concentration 2%; mix the antimicrobial peptide with 95% alcohol to obtain the antimicrobial peptide solution, control the antimicrobial peptide concentration at 7%; The antimicrobial peptide solution and the pectin solution were mixed in a ratio of 3:1 by volume, and reacted at 12°C for 2h; The solution was washed, and then washed with 60% alcohol; the filter cake was dried at 60°C, crushed, and pectin modified with antimicrobial peptides.

[0023] Concentration is that the pectin modified by 3wt% antimicrobial peptide is dissolved in the concentration of 1wt% acetic acid solution, then add glycerol thereinto, the dosage of glycerol is 25% of the quality of the pectin modified by antimicrobial peptide, prepare antimicrobial peptide modified pectin solution. 10 wt% collagen was dissolved in distilled water, and glycerin was added in an amount of 25% of the mass of...

Embodiment 2

[0029] This embodiment is basically the same as Example 1, except that the pectin concentration in the pectin solution is 2%; the antimicrobial peptide is mixed with 95% alcohol to obtain the antimicrobial peptide solution, and the antimicrobial peptide concentration is controlled at 6%. After the reaction finishes, take out the precipitate, filter, and the filter cake is washed with 60% alcohol, then washed with 60% alcohol solution of pH2, and then washed with 60% alcohol; : 1 ratio mixed, 10 ℃ reaction 3h; Concentration is that the pectin modified by 3wt% antimicrobial peptide is dissolved in the acetic acid solution that concentration is 0.5wt%, then adds glycerol thereinto, and the dosage of glycerol is the pectin modified by antimicrobial peptide The quality of the glue is to prepare a pectin solution modified by antimicrobial peptide; the mass ratio of pectin modified by antimicrobial peptide to collagen in the film-forming solution is 1:0.3, and the pH of the film-formi...

Embodiment 3

[0031] The present embodiment is basically the same as Example 1, except that the concentration of pectin in the pectin solution is 5%; the antimicrobial peptide is mixed with 95% alcohol to obtain the antimicrobial peptide solution, and the concentration of the antimicrobial peptide is controlled at 1%. After the reaction finishes, the precipitate is taken out, filtered, and the filter cake is washed with 60% alcohol, then washed with 60% alcohol solution of pH5, and then washed with 60% alcohol; : 1 ratio mixing, 15 ℃ of reaction 1h; Concentration is that the pectin modified by 3wt% antimicrobial peptide is dissolved in the acetic acid solution that concentration is 2wt%, then adds glycerol wherein, the dosage of glycerol is the pectin modified by antimicrobial peptide 10% of the mass of the film-forming solution; the mass ratio of antimicrobial peptide-modified pectin to collagen in the film-forming solution is 1:0.8, and the pH of the film-forming solution is 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com