Pd/FeOOH@RGO Pickering emulsion and application thereof in catalyzing carbon-carbon coupling reaction

A Pickering emulsion and carbon-carbon coupling technology, applied in the field of catalysis, can solve the problems of difficult reaction, time-consuming, and difficult synthesis of ligands in organic reactions, and achieve the effects of low production cost, high efficiency, and good amphiphilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

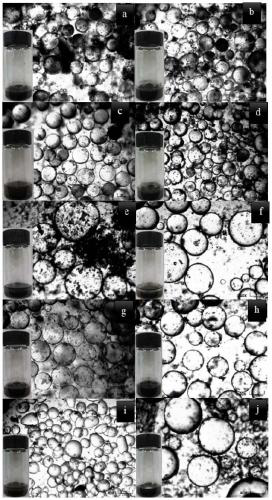

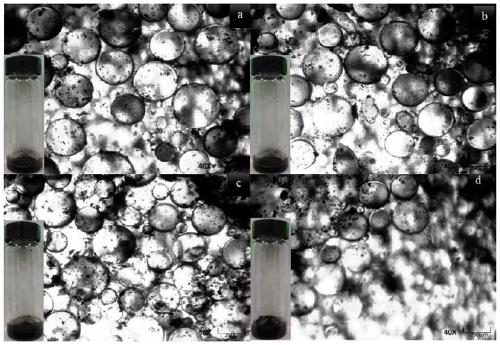

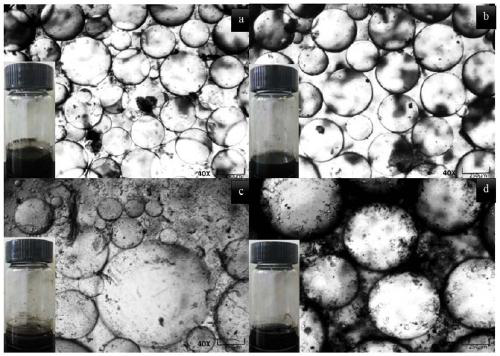

[0023] 1. Add 125 mg of graphite oxide (GO) into 15 mL of deionized water, and ultrasonically disperse to obtain a graphite oxide dispersion. Under stirring conditions, add 1 mg of palladium chloride to the graphite oxide dispersion, then transfer to a 150 mL round bottom flask, add 15 mL of acetonitrile solution of iron pentacarbonyl with a volume concentration of 16.7 mL / L, and react at 60 ° C under airtight conditions for 3 hours, after the reaction was completed, it was filtered, washed with deionized water, and freeze-dried to obtain a nano-iron oxyhydroxide / palladium / graphene ternary composite material, which was denoted as Pd / FeOOH@RGO.

[0024] 2. Weigh 10mg of Pd / FeOOH@RGO and ultrasonically disperse in 2mL of deionized water to obtain a Pd / FeOOH@RGO dispersion with a concentration of 5mg / mL. Under stirring conditions, 2 mL of n-heptane was added to the Pd / FeOOH@RGO dispersion, and the Pd / FeOOH@RGO Pickering emulsion was obtained by shaking with a homogenizer.

[002...

Embodiment 2

[0029]1. Add 25 mg of graphite oxide into 5 mL of deionized water, and ultrasonically disperse to obtain a graphite oxide dispersion. Under stirring conditions, add 5 mg of palladium chloride to the graphite oxide dispersion, then move to a 150 mL round bottom flask, add 15 mL of acetonitrile solution with a volume concentration of 5 mL / L iron pentacarbonyl, and react at 50 °C for 2 hours under airtight conditions. After the reaction, it was filtered, washed with deionized water, and freeze-dried to obtain Pd / FeOOH@RGO.

[0030] 2. Weigh 10mg of Pd / FeOOH@RGO and ultrasonically disperse in 2mL of deionized water to obtain a Pd / FeOOH@RGO dispersion with a concentration of 5mg / mL. Under stirring conditions, 2 mL of n-heptane was added to the Pd / FeOOH@RGO dispersion, and the Pd / FeOOH@RGO Pickering emulsion was obtained by shaking with a homogenizer.

Embodiment 3

[0032] 1. Add 25 mg of graphite oxide into 5 mL of deionized water, and ultrasonically disperse to obtain a graphite oxide dispersion. Under stirring conditions, add 5 mg of palladium chloride to the graphite oxide dispersion, then move to a 150 mL round bottom flask, add 15 mL of acetonitrile solution with a volume concentration of 20 mL / L iron pentacarbonyl, and react at 50 °C for 2 hours under airtight conditions. After the reaction, it was filtered, washed with deionized water, and freeze-dried to obtain Pd / FeOOH@RGO.

[0033] 2. Weigh 10mg of Pd / FeOOH@RGO, and ultrasonically disperse it in 10mL of deionized water to obtain a Pd / FeOOH@RGO dispersion with a concentration of 1mg / mL. Under stirring conditions, 10 mL of n-heptane was added to the Pd / FeOOH@RGO dispersion, and the Pd / FeOOH@RGO Pickering emulsion was obtained by shaking with a homogenizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com