Supermolecule composite nanofiltration membrane and preparation method and application thereof

A composite nanofiltration membrane and supramolecular technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of low yield and complex production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

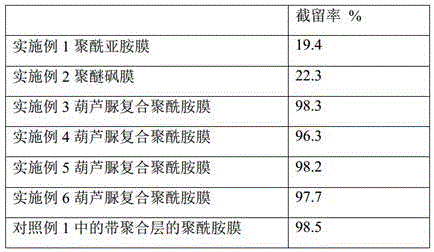

Embodiment 1

[0051] Example 1 Preparation of polyimide base film

[0052] ⑴ Dissolve polyimide (P84) and polyethylene glycol 400 (PEG) in N-methylpyrrolidone (NMP) solvent in a certain mass ratio, the mass ratio of P84, PEG and NMP is 20:12:50, Stir mechanically at room temperature of 25°C for 20-24 hours, and after it is completely dissolved, let it stand for 8-12 hours for degassing treatment to obtain the casting solution;

[0053] (2) Fix the polyester non-woven fabric on the glass plate, control the thickness of the scraper to 100 μm, scrape and coat the casting solution on the polyester non-woven fabric, control the volatilization time for 5-10 seconds, immerse in the water coagulation bath, and phase Separate and solidify to form a film, take it out after soaking for 5 minutes to obtain a wet polyimide film, and store the prepared base film in deionized water.

[0054] The prepared polyimide nanofiltration membrane base layer was used for the preparation of the modification layer i...

Embodiment 2

[0055] The preparation of embodiment 2 polyethersulfone base membrane

[0056] ⑴ Dissolve polyethersulfone and polyethylene glycol 400 (PEG) in N-methylpyrrolidone (NMP) solvent in a certain mass ratio, the mass ratio of P84, PEG and NMP is 20:12:50, at 25°C Under mechanical stirring for 20-24 hours, after it is completely dissolved, let it stand for 8-12 hours for degassing treatment, and the obtained casting solution;

[0057] (2) Fix the polyester non-woven fabric on the glass plate, control the thickness of the scraper to 100 μm, scrape and coat the casting solution on the polyester non-woven fabric, control the volatilization time for 5-10 seconds, immerse in the water coagulation bath, and phase Separate and solidify to form a film, take it out after soaking for 5 minutes to obtain a wet polyethersulfone film, and store the prepared base film in deionized water.

[0058] The prepared polyethersulfone-based membrane was used for the preparation of the modified layer in t...

Embodiment 3

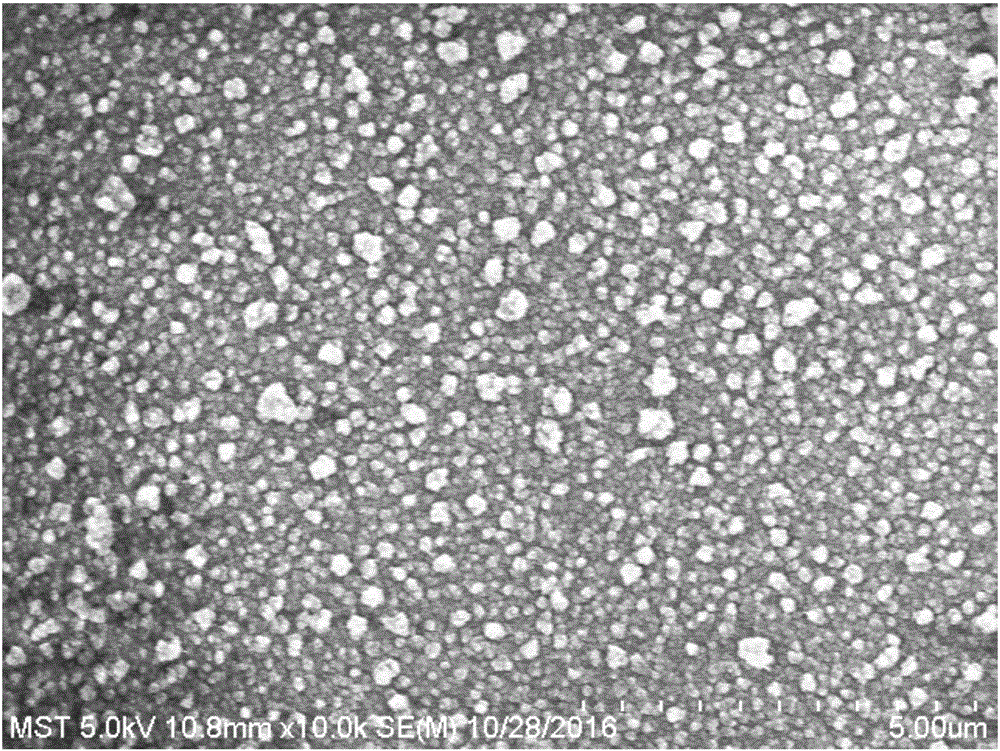

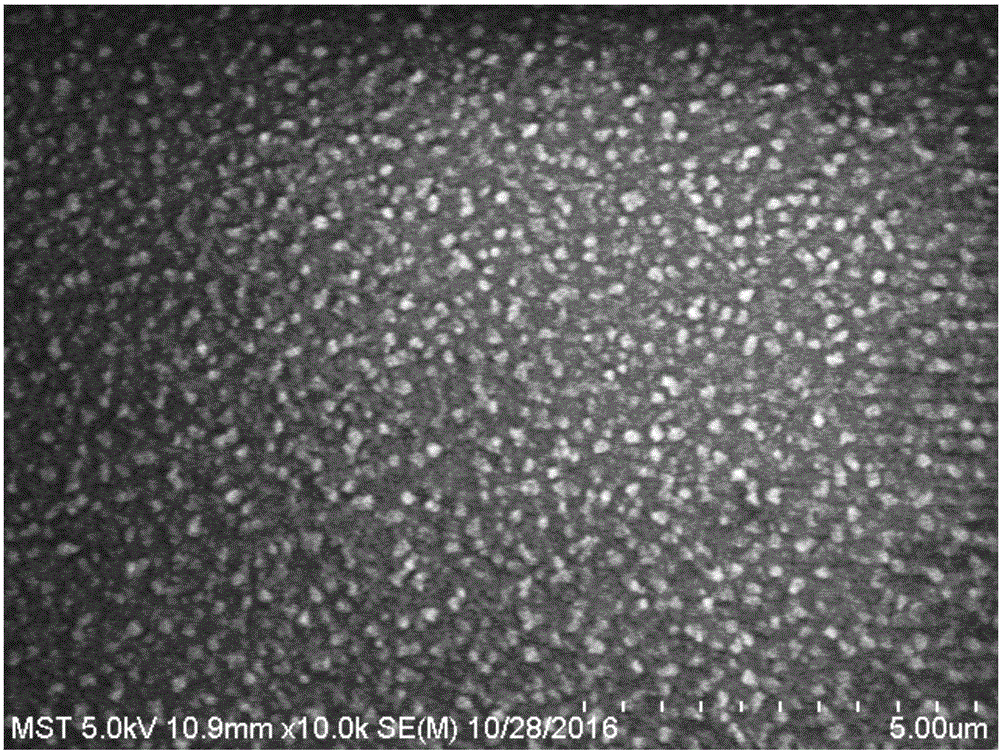

[0059] The preparation of the polyimide composite film of embodiment 3 cucurbituril modification

[0060] Prepare 2wt% anhydrous piperazine (PIP) aqueous phase solution, add 0.1wt% cucurbitacin 6 (CB6), stir until completely dissolved, as the first phase;

[0061] Preparation of 0.1 wt% trimesoyl chloride organic phase solution, organic solvent is n-hexane, as the second phase;

[0062] Fix the polyimide base film on the interface polymerization device, pour a certain amount of the first phase solution to immerse the surface of the film, make it contact with the surface for 120 seconds, take it out, and then roll the polyimide support film with a rubber roller, Remove excess solution, pour an equal amount of the second phase, soak for 60 seconds, rinse the surface with n-hexane solution after the reaction is complete, remove excess reactants and store in pure water for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com