Descending wet electrostatic precipitation, demisting and ultra-low flue gas emission device

A technology of wet electrostatic dust removal and discharge device, applied in electrostatic separation, electrostatic effect separation, external electrostatic separator, etc., can solve the problems of high investment and operation costs, easy fouling of internal components, long construction period, etc., and achieve improvement Dust removal efficiency, not easy to hang ash and scale, easy to replace and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

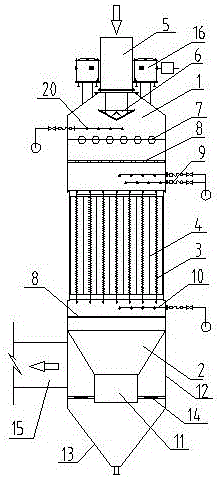

[0019] A downward wet type electrostatic dust removal and mist removal ultra-low smoke emission device, comprising an upper air chamber 1 and a lower air chamber 2 and an electrostatic dust removal device located between the two. The electrostatic dust removal device includes a corona electrode system 3 and a precipitation Electrode system 4, the upper end of the upper air chamber 1 is provided with an air inlet pipe 5, the upper air chamber 1 is provided with a V-shaped air flow distributor 6 at the air inlet end, and several layers are provided below the V-shaped air distributor 6 The flue gas uniform distribution device 7, the upper air chamber 1 and the lower air chamber 2 are both bell-mouthed and the two bell mouths are opposite. The flue gas uniform distribution device 7 of the upper air chamber 1 and the upper part of the lower air chamber 2 are both A flue gas flow stabilization device 8 is provided, a flushing device 9 is provided below the flue gas flow stabilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com