Anti-oxidization steam turbine blade

A steam turbine blade and anti-oxidation technology, which is applied in the field of steam turbine blades, can solve problems such as poor anti-oxidation performance, and achieve the effects of prolonging service life, avoiding blade oxidation and not easy to rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

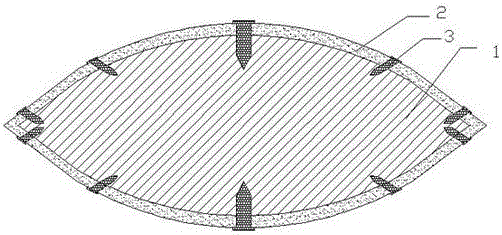

[0042] An anti-oxidation steam turbine blade, comprising a blade base layer 1, characterized in that: the blade base layer 1 is coated with an anti-oxidation layer 2, and the anti-oxidation layer 2 includes an inner layer 20, a lining layer 21 and an outer layer 22, the inner layer The layer 20 is a waterproof material layer, the lining layer 21 is a basalt fiber composite layer, the outer layer 22 is a stainless steel composite layer, and the anti-oxidation layer 2 is fixed on the blade base layer 1 by screws 3 .

[0043] The basalt fiber composite layer is composed of the following components in parts by weight:

[0044] Basalt fiber 26 parts

[0045] 9 parts glass fiber

[0046] Metal fiber 12 parts

[0047] Carbon fiber 8 parts.

[0048] The stainless steel composite layer includes a low carbon steel layer 220 , a high manganese steel layer 221 and a 304 stainless steel layer 222 , the low carbon steel layer 220 is located inside the high manganese steel layer 221 , and...

Embodiment 2

[0060]An anti-oxidation steam turbine blade, comprising a blade base layer 1, characterized in that: the blade base layer 1 is coated with an anti-oxidation layer 2, and the anti-oxidation layer 2 includes an inner layer 20, a lining layer 21 and an outer layer 22, the inner layer The layer 20 is a waterproof material layer, the lining layer 21 is a basalt fiber composite layer, the outer layer 22 is a stainless steel composite layer, and the anti-oxidation layer 2 is fixed on the blade base layer 1 by screws 3 .

[0061] The basalt fiber composite layer is composed of the following components in parts by weight:

[0062] Basalt fiber 32 parts

[0063] 9 parts glass fiber

[0064] Metal fiber 6 parts

[0065] Carbon fiber 16 parts.

[0066] The stainless steel composite layer includes a low carbon steel layer 220 , a high manganese steel layer 221 and a 304 stainless steel layer 222 , the low carbon steel layer 220 is located inside the high manganese steel layer 221 , and ...

Embodiment 3

[0078] An anti-oxidation steam turbine blade, comprising a blade base layer 1, characterized in that: the blade base layer 1 is coated with an anti-oxidation layer 2, and the anti-oxidation layer 2 includes an inner layer 20, a lining layer 21 and an outer layer 22, the inner layer The layer 20 is a waterproof material layer, the lining layer 21 is a basalt fiber composite layer, the outer layer 22 is a stainless steel composite layer, and the anti-oxidation layer 2 is fixed on the blade base layer 1 by screws 3 .

[0079] The basalt fiber composite layer is composed of the following components in parts by weight:

[0080] Basalt fiber 28 parts

[0081] 5 parts glass fiber

[0082] Metal fiber 10 parts

[0083] Carbon fiber 12 parts.

[0084] The stainless steel composite layer includes a low carbon steel layer 220 , a high manganese steel layer 221 and a 304 stainless steel layer 222 , the low carbon steel layer 220 is located inside the high manganese steel layer 221 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com