Multifunctional multi-layer coextrusion plastic bottle

A multi-layer co-extrusion, plastic bottle technology, applied in the fields of pharmaceutical packaging and food, can solve the problems of high production cost, low barrier property, and drug deterioration, meet the low n-hexane dissolution index, ensure drug safety, and good sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

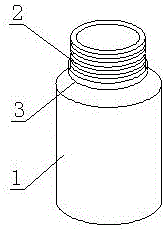

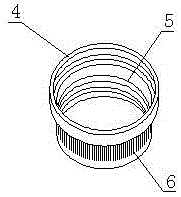

[0030] A multi-functional multi-layer co-extruded plastic bottle, including a bottle body and a bottle cap. The material of the bottle body is composed of three layers of materials, namely an outer layer, a middle layer and an inner layer. The bottle body is manufactured by multi-layer co-extrusion technology . The material of the outer layer is polyolefin eluted with low n-hexane; the middle layer is polyvinylidene chloride (PVDC); the inner layer is polyolefin eluted with low n-hexane with silver ions added.

Embodiment 2

[0032] A multi-functional multi-layer co-extruded plastic bottle, including a bottle body and a bottle cap. The material of the bottle body is composed of three layers of materials, namely an outer layer, a middle layer and an inner layer. The bottle body is manufactured by multi-layer co-extrusion technology . The material of the outer layer is low n-hexane eluted polyolefin; the middle layer is made of vinyl alcohol copolymer (EVOH); the inner layer is made of low n-hexane eluted polyolefin added with silver ions.

Embodiment 3

[0034] A multi-functional multi-layer co-extruded plastic bottle, including a bottle body and a bottle cap. The material of the bottle body is composed of five layers of materials, wherein the five layers are the outer layer, the middle layer 1, the middle layer 2, the middle layer 3 and the inner layer , the bottle body is manufactured by multi-layer co-extrusion technology. The material of the outer layer is polyolefin eluted with low n-hexane; the middle layer 1 adopts polyvinylidene chloride (PVDC); the middle layer 2 adopts vinyl alcohol copolymer (EVOH); the middle layer 3 adopts nylon; Low n-hexane leached polyolefins.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com