A kind of device for preparing graphene

A graphene and graphite technology, applied in the field of devices for preparing graphene, can solve problems such as low product quality, toxicity of reducing agents, environmental pollution, etc., and achieve the effects of high preparation efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

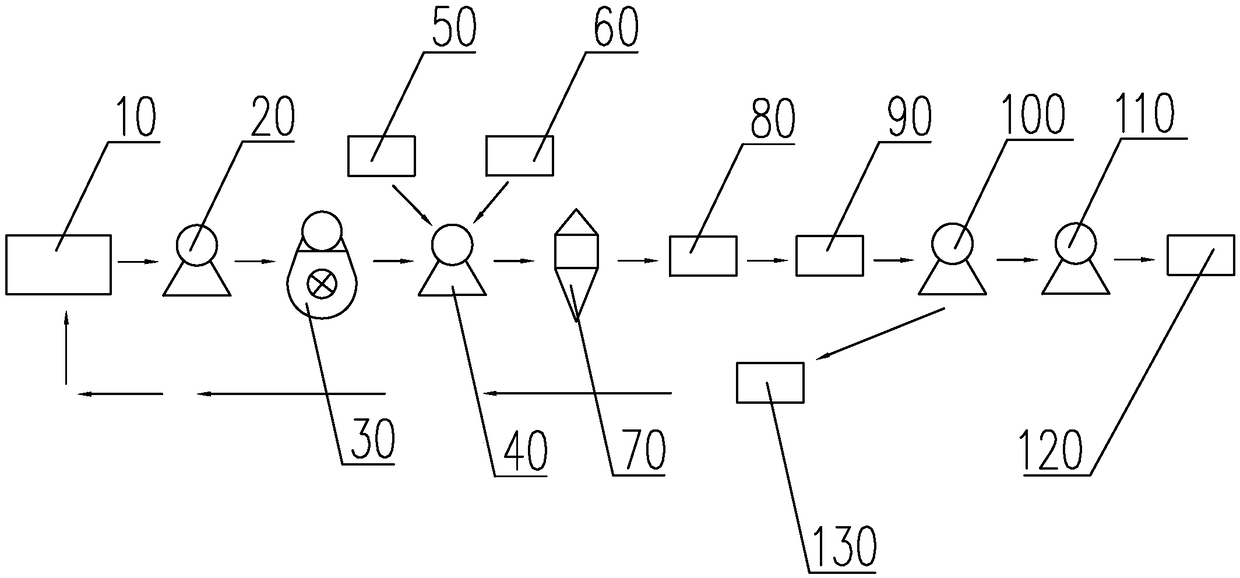

[0034] A device for preparing graphene, such as figure 1 shown, which includes

[0035] Screening mechanism 10, used for screening graphite processing, described screening mechanism 10 is a 1000-purpose screening machine;

[0036] The first reaction kettle 20 is used to crack the graphite raw material screened out, and the first reaction kettle is a microwave cracking device, a light wave cracking device or a laser cracking device;

[0037] A stirring mechanism 30, which obtains a graphite-stripping agent mixed solution by mixing the cracked graphite discharge and the stripping agent;

[0038] The second reaction kettle 40 is used to hold graphite-stripping agent mixed solution;

[0039] The bubble generating mechanism 50 is used to inflate the graphite-stripping agent mixed solution contained in the second reaction kettle 40;

[0040] The ultrasonic blasting mechanism 60 is used to detonate the bubbles in the graphite-stripping agent mixed solution in the second reactor 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com