Preparation method of super-hydrophobic graphene aerogel

A technology of graphene airgel and graphene hydrogel, which is applied in the direction of graphene, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve problems such as large-scale difficulties and limitations, and achieve low cost Low cost, easy operation, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. Disperse graphene oxide in deionized water, and ultrasonically disperse to form a graphene oxide aqueous solution with a uniform concentration of 2 mg / mL;

[0021] b. Add a reducing agent of 1 mg / mL ascorbic acid to the graphene oxide solution obtained in step a, stir evenly with a magnetic force, then pour it into a container and seal it, then heat it in an oven at a temperature of 60°C and a holding time of 2 hours to obtain Graphene hydrogel;

[0022] c. After immersing and cleaning the graphene hydrogel obtained in step b with deionized water, perform directional freezing at a temperature of -196° C. to obtain a frozen sample, and then freeze-dry to obtain a freeze-dried sample;

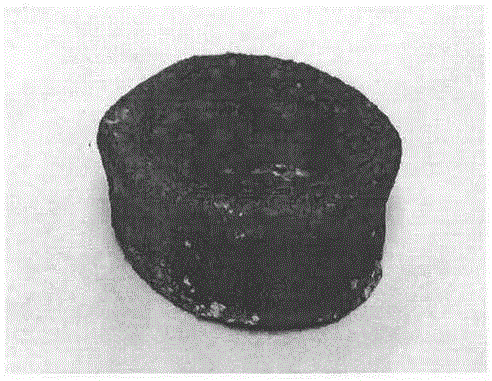

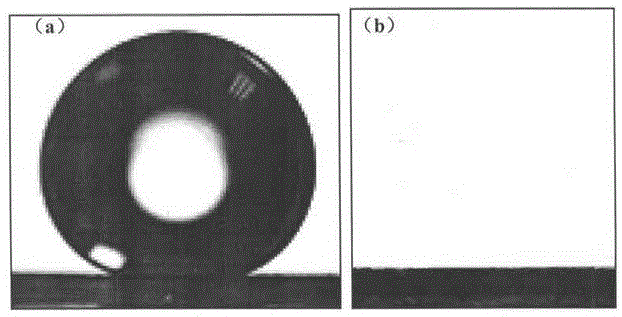

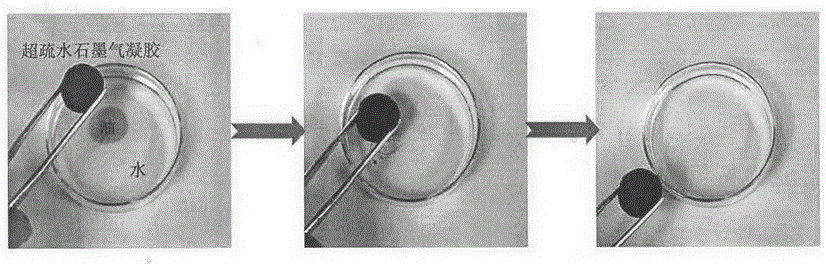

[0023] d. Put the freeze-dried sample into an airtight container containing a long carbon chain alkoxysilane material-ethanol solution with a carbon chain length of 6 carbon atoms at a concentration of 1 wt%, react at a temperature of 50°C for 24 hours, and dry Then the superhydrophobi...

Embodiment 2

[0025] a. Disperse graphene oxide in deionized water, and ultrasonically disperse to form a graphene oxide aqueous solution with a uniform concentration of 4 mg / mL;

[0026] b. Add 0.5 mg / mL of dopamine and 4 mg / mL of ascorbic acid as the reducing agent to the graphene oxide solution obtained in step a, stir evenly with a magnetic force, then pour it into a container and seal it, heat it in an oven at a temperature of 70°C, and keep it warm The time is 6 hours, and the graphene hydrogel is obtained;

[0027] c. After immersing and cleaning the graphene hydrogel obtained in step b with deionized water, perform directional freezing at a temperature of -196° C. to obtain a frozen sample, and then freeze-dry to obtain a freeze-dried sample;

[0028] d. Put the freeze-dried sample into an airtight container containing a fluorinated long carbon chain alkoxysilane material-ethanol solution with a carbon chain length of 12 carbon atoms at a concentration of 2 wt%, and react at a tempe...

Embodiment 3

[0030] a, disperse graphene oxide in deionized water, and ultrasonically disperse to form a graphene oxide aqueous solution with a uniform concentration of 6 mg / mL;

[0031] b. Add 1 mg / mL of dopamine and 8 mg / mL of ascorbic acid as the reducing agent to the graphene oxide solution obtained in step a, stir evenly with a magnetic force, then pour it into a container and seal it, then heat it in an oven at a temperature of 80°C for a holding time For 8 hours, the graphene hydrogel was obtained;

[0032] c. After immersing and cleaning the graphene hydrogel obtained in step b with deionized water, perform directional freezing at a temperature of -196° C. to obtain a frozen sample, and then freeze-dry to obtain a freeze-dried sample;

[0033] d. Put the freeze-dried sample into an airtight container containing a long carbon chain alkoxysilane material-ethanol solution with a carbon chain length of 18 carbon atoms at a concentration of 3 wt%, react at a temperature of 70°C for 8 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com