Treatment technology of waste water containing fluoride and ammonia nitrogen

A technology of ammonia nitrogen wastewater and treatment process, which is applied in metallurgical wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of secondary pollution, demanding water pretreatment, high investment, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

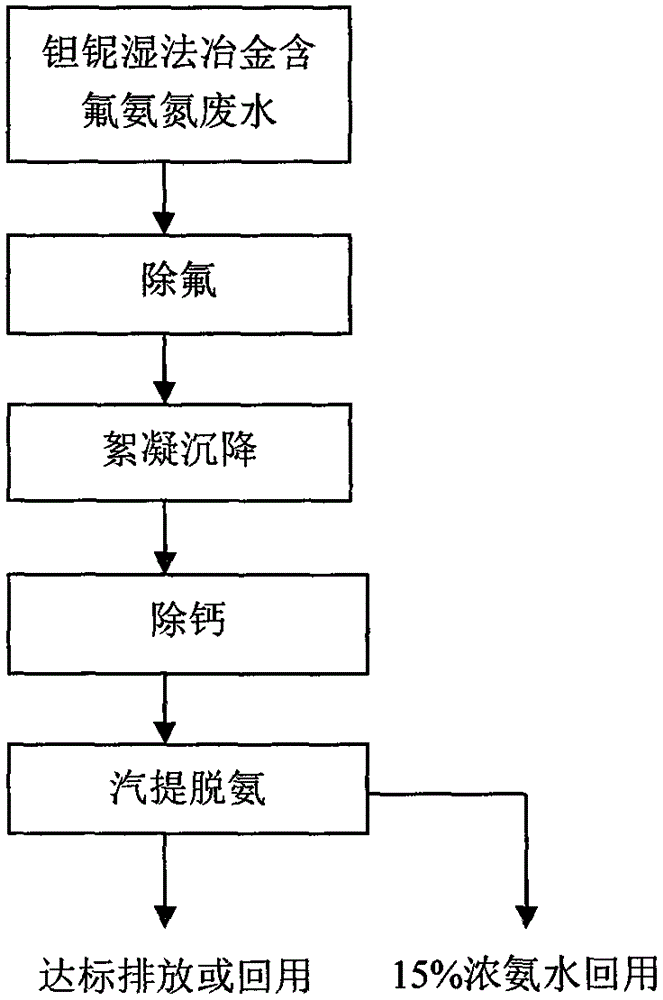

[0024] The invention provides a kind of processing technology of fluorine-containing ammonia nitrogen wastewater, the embodiment of technology is as follows:

[0025] The water quality of fluorine-containing ammonia wastewater produced in a tantalum-niobium hydrometallurgical process is:

[0026] Wastewater components Ammonia nitrogen pH Cl F -

SO 4 2-

Ca Mg unit (g / L) (g / L) (g / L) (g / L) (mg / L) (mg / L) value 81 9.5 6.3 12.5 7.2 0.018 0.017

[0027] Mix the fluorine-containing ammonia wastewater to be treated with lime milk, adjust the pH to 10-14, make fluoride ions and sulfate ions generate calcium fluoride and calcium sulfate and remove them, add flocculant PAM (polyacrylamide) to make calcium fluoride and sulfuric acid Calcium precipitates, and at the same time makes most of the NH 4 F, (NH 4 ) 2 SO 4 The ammonium in the ammonia is converted into free ammonia, making it easier to volatilize in the subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com