Method for modifying dry de-sliming tail mud, and application thereof

A tailings and modification technology, applied in the field of solid waste resource utilization, can solve problems such as loss and adverse effects on high-grade road quality, and achieve the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A modification method for dry desludge tailings, which comprises the following steps:

[0057] 1) Mix the catalyst (iron oxide red) with the dry desliming tailings evenly to obtain mixed tailings, wherein the catalyst accounts for 3% of the mass of the dry desliming tailings;

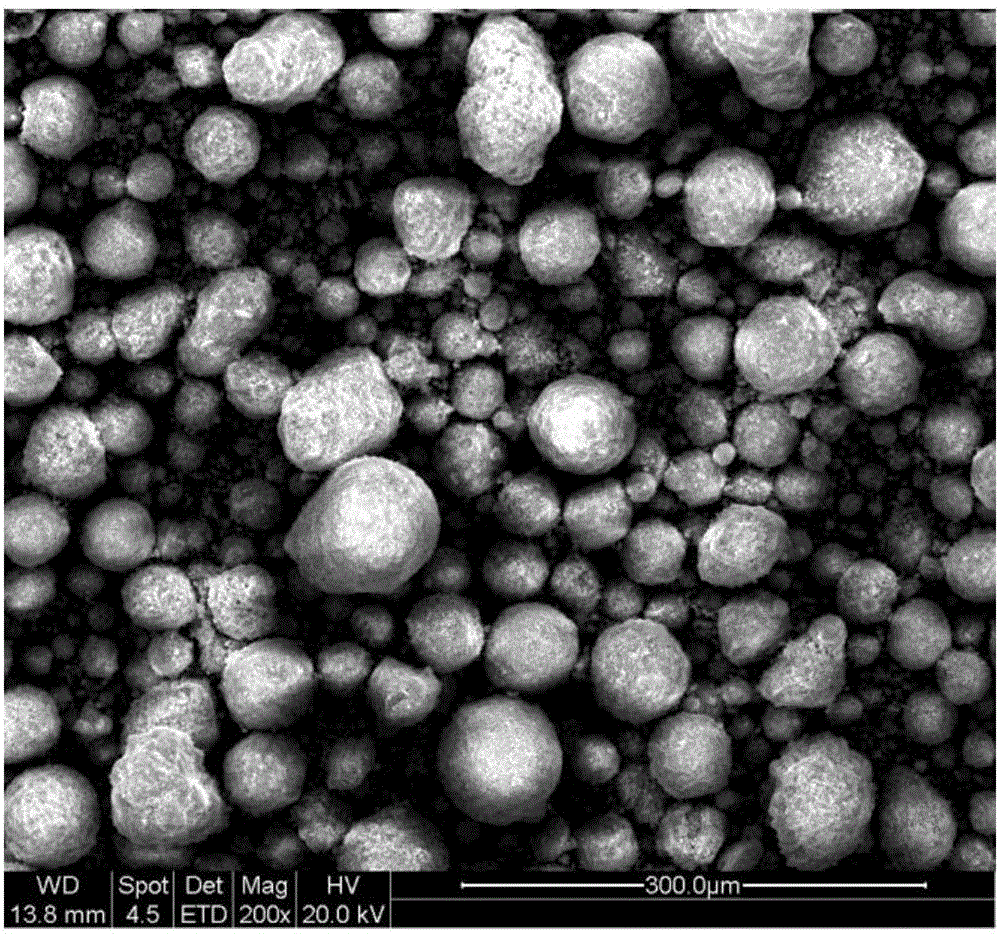

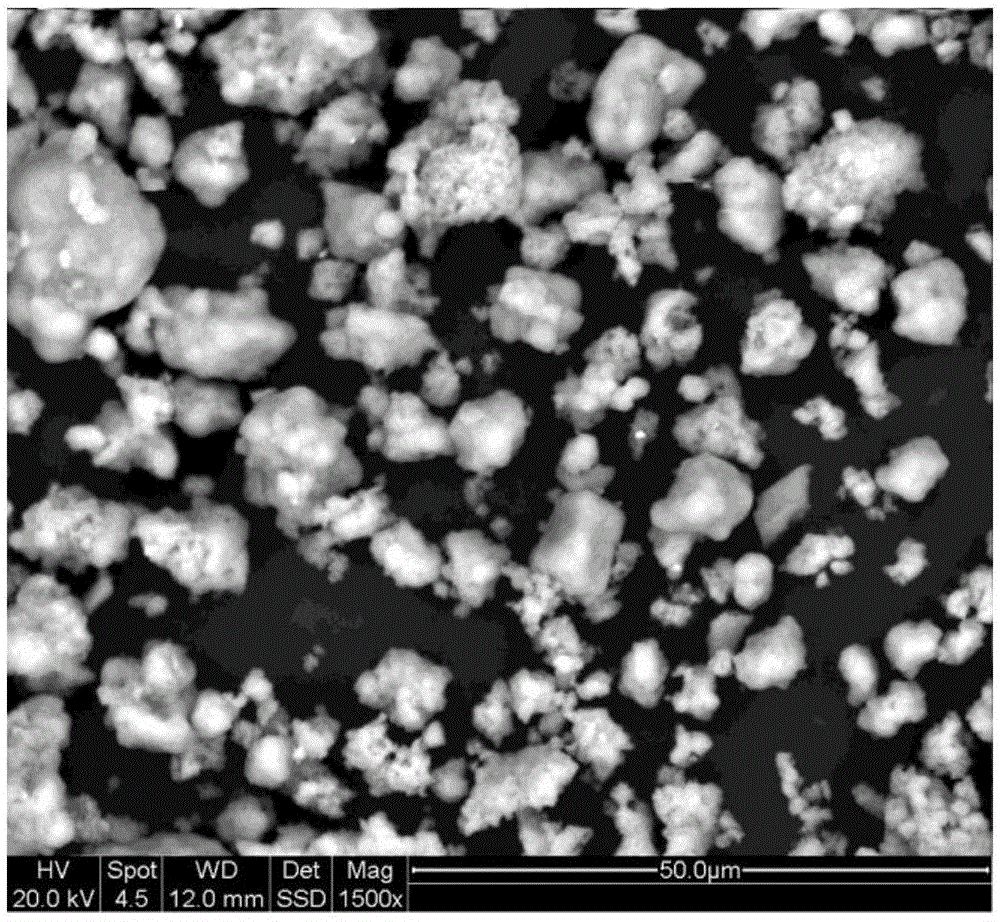

[0058] 2) Mix 1 volume of acidifying agent (acetic acid) into 10 volumes of water to form a wetting solution, spray the wetting solution accounting for 10% of the mass of dry desliming tailings into the mixed tailings, and mix evenly again to make the tailings In a wet state, wet tailings were obtained, and the obtained wet tailings were observed with a scanning electron microscope. The results showed that the particle size of the modified desliming agent was the same as that before the modification ( figure 1 ) is lower than that, and the original spherical feature disappears, and the particles have a certain polyhedral shape;

[0059] 3) Cover the obtained wet tailings with plastic cloth for 2...

Embodiment 2

[0064] A modification method for dry desludge tailings, which comprises the following steps:

[0065] 1) Mix the catalyst (iron oxide red) with the dry desliming tailings uniformly to obtain mixed tailings, wherein the catalyst accounts for 4% of the mass of the dry desliming tailings;

[0066] 2) Mix 1 volume of acidifier (propionic acid) into 12 volumes of water to form a wetting solution, spray the wetting solution accounting for 10% of the mass of the dry desliming tailings into the mixed tailings, and mix evenly again to make the tailings The mud is in a wet state, and the tailings must be moistened;

[0067] 3) Cover the obtained wet tailings with plastic cloth for 18 hours;

[0068] 4) Remove the plastic cloth and continue to age for 30 days to obtain the modified deslimed tailings.

[0069] Apply the modified desliming tailings obtained in this example to be used as roadbed materials, and the specific steps are as follows:

[0070] A secondary road project requires ...

Embodiment 3

[0072] A modification method for dry desludge tailings, which comprises the following steps:

[0073] 1) Mix the catalyst (iron oxide red) with the dry desliming tailings evenly to obtain mixed tailings, wherein the catalyst accounts for 5% of the mass of the dry desliming tailings;

[0074] 2) Mix 1 volume of acidifying agent (formic acid: acetic acid = 1:1) into 9 volumes of water to form a wetting solution, spray the wetting solution accounting for 8% of the mass of the dry desliming tailings into the mixed tailings, and again Mix evenly so that the tailings are in a wet state, and the tailings must be wet;

[0075] 3) Cover the obtained wet tailings with plastic cloth for 26 hours;

[0076] 4) Remove the plastic cloth and continue to age for 20 days to obtain the modified deslimed tailings.

[0077] Apply the modified desliming tailings obtained in this example to be used as roadbed materials, and the specific steps are as follows:

[0078] A tertiary road project requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com