Porous sponge concrete and preparation process thereof

A technology of porous sponge and concrete, applied in the field of concrete materials, can solve the problems of easy blocking of pores of porous cement concrete, low strength of porous cement concrete, low strength of porous concrete, etc., so as to reduce the bad phenomenon, improve the strength, and reduce the water used for molding. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

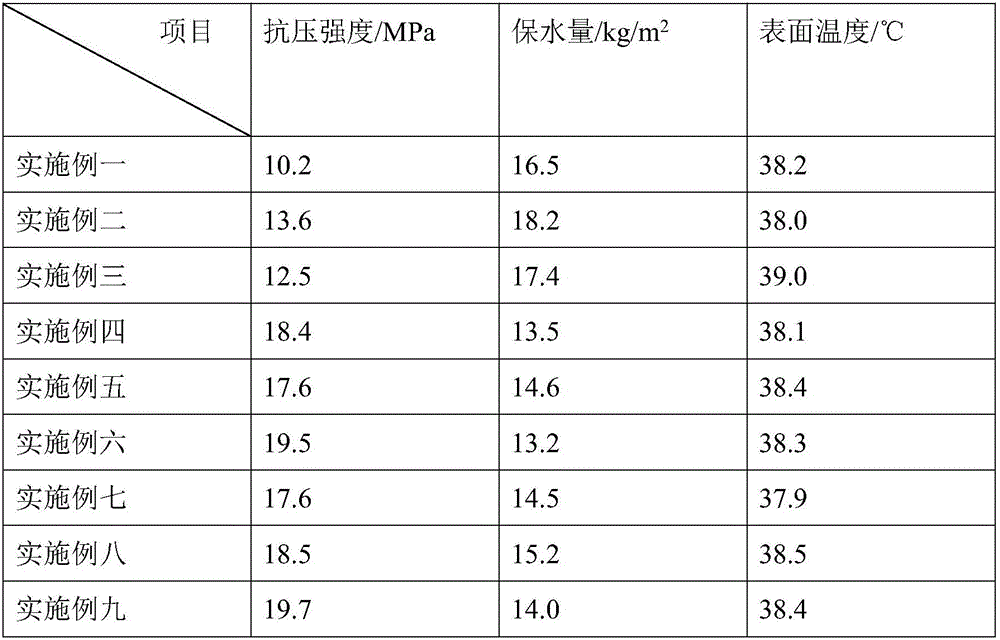

Examples

Embodiment 1

[0034] Porous sponge concrete, including cement, coarse aggregate, water, dispersant, foaming agent, rubber powder and porous sponge, and the weight ratio of cement, aggregate and water is 1:4:0.3;

[0035] Described cement is portland cement;

[0036] The particle size of the aggregate is pebbles of 10-20mm;

[0037] The dispersant is a sulfonated melamine water reducer, and the dosage is 1% by weight of cement;

[0038] Described foaming agent is that foaming agent is sodium dodecylbenzene sulfonate, and consumption is 0.1% of cement mass;

[0039] The rubber powder is an ethylene-vinyl acetate copolymer water-soluble redispersible powder, and the consumption is 0.5% of the cement weight;

[0040] The porous sponge is made of polyvinyl alcohol and is in a granular state with a particle diameter of 2-5mm and a weight of 0.5% of the weight of the aggregate.

[0041] The preparation technology of porous sponge concrete is characterized in that comprising the following steps:...

Embodiment 2

[0047] Porous sponge concrete, including cement, coarse aggregate, water, dispersant, foaming agent, rubber powder and porous sponge, and the weight ratio of cement, aggregate and water is 1:9:0.5;

[0048] Described cement is aluminate cement;

[0049] The particle size of the aggregate is slag waste of 8-16 mm;

[0050] The dispersant is a sulfonated melamine water reducer, and the dosage is 1% by weight of cement;

[0051] Described foaming agent is that foaming agent is sodium lauryl sulfate, and consumption is cement quality 1%;

[0052] The rubber powder is a copolymer water-soluble redispersible powder of vinyl acetate-ethylene tertiary carbonate copolymer, and the consumption is 1% of cement weight;

[0053] The porous sponge is made of polyvinyl alcohol and is in a granular state with a particle diameter of 5-10 mm and a weight of 0.2% of the weight of the aggregate.

[0054] The preparation process is the same as in Example 1.

Embodiment 3

[0056] Porous sponge concrete, including cement, coarse aggregate, water, dispersant, foaming agent, rubber powder and porous sponge, and the weight ratio of cement, aggregate and water is 1:7:0.4;

[0057] Described cement is portland cement;

[0058]The particle size of the aggregate is crushed stone of 10-23 mm;

[0059] The dispersant is a polycarboxylate water reducer, and the dosage is 0.1% by weight of cement;

[0060] Described foaming agent is that foaming agent is sodium lauryl sulfate, and consumption is cement quality 1%;

[0061] The rubber powder is a copolymer water-soluble redispersible powder of acrylic acid copolymer, and the consumption is 0.8% of cement weight;

[0062] The porous sponge is made of polyvinyl alcohol and is in a granular state with a particle diameter of 4-8mm and a weight of 0.3% of the weight of the aggregate.

[0063] The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com