Method for solidifying ceramic slurry by employing metal ions in temperature-controlled slow-release sintering aid

A technology of ceramic slurry and metal ions, which is applied in the field of curing ceramic slurry by using metal ions in temperature-controlled slow-release sintering aids, can solve the problems of low strength of ceramic green blanks, long curing time, and uneven curing uniformity, etc. Facilitate large-scale production, good uniformity, improved density and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

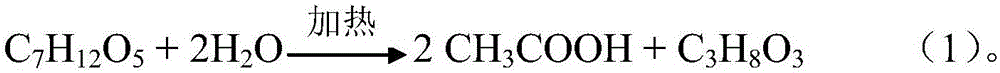

Method used

Image

Examples

Embodiment 1

[0044] 0.7 wt% magnesia, 2.0 vol% diacetin solidified 50 vol% alumina slurry dispersed with 0.2 wt% ammonium citrate.

[0045] Mix 50 grams of alumina powder, 0.35 grams of magnesium oxide, 0.1 grams of ammonium citrate and 12.6 grams of water, and ball mill for 1.0 hour at a ball milling speed of 250 r / min to prepare negatively charged particles with a solid phase volume fraction of 50%. Then stir and degas under vacuum for 20 minutes, then add 0.68 ml of glycerol diacetate, stir with a glass rod for 30 seconds, then inject into the mold, place it at 70°C for 1 hour, then demould, and dry at 90°C After 24 hours, the temperature was raised to 1550° C. at a heating rate of 3° C. / min and kept for 4 hours for sintering. The relative theoretical density of the obtained ceramic dry body is 51.3%, and the shrinkage rate is 2.4%; the relative theoretical density of the obtained ceramic sintered part is 99.2%, and the shrinkage rate is 17.2%.

Embodiment 2

[0047] 1.5wt% magnesia, 0.5vol% glycerol triacetate solidified 55vol% zirconia slurry dispersed in 0.8wt% tetramethylammonium hydroxide.

[0048] Mix 50 grams of zirconia powder, 0.75 grams of magnesium oxide, 0.4 grams of tetramethylammonium hydroxide and 7.0 grams of water, and ball mill at a ball milling rate of 400 r / min for 0.5 hours to prepare particles with a solid phase volume fraction of 55%. Negatively charged ceramic slurry on the surface, then stirred and degassed under vacuum for 20 minutes, then added 0.15 ml of glycerol triacetate, stirred the glass rod for 15 seconds and then injected into the mold. ℃ for 48 hours, and then heated to 1450 ℃ at a heating rate of 6 ℃ / min for 6 hours for sintering. The relative theoretical density of the obtained ceramic dry body is 56.7%, and the shrinkage rate is 2.4%; the relative theoretical density of the obtained ceramic sintered part is 99.4%, and the shrinkage rate is 18.4%.

Embodiment 3

[0050] 1.0 wt% yttrium oxide, 3.0 vol% ethyl acetate solidified 50 vol% silicon nitride slurry dispersed in 0.2 wt% tetramethylammonium hydroxide.

[0051] 50 grams of silicon nitride powder, 0.5 grams of yttrium oxide, 0.1 grams of tetramethylammonium hydroxide and 15.7 grams of water were mixed, and ball milled at a ball milling rate of 200 r / min for 1.5 hours to prepare a solid phase volume fraction of 50%. Negatively charged ceramic slurry on the surface of the particles, then stirred and degassed under vacuum for 10 minutes, then added 0.47 ml of ethyl acetate, stirred the glass rod for 10 seconds, then injected into the mold, placed at 60 ° C for 1 hour, and demolded at 80 °C ℃ for 24 hours, and then heated to 1800 ℃ at a heating rate of 3 ℃ / min for 8 hours for sintering. The relative theoretical density of the obtained ceramic dry body is 57.2%, and the shrinkage rate is 2.3%; the relative theoretical density of the obtained ceramic sintered part is 99.0%, and the shrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com