Synthetic process for sodium gualenate monohydrate

A technology of sodium azulene sulfonate and monohydrate, which is applied in the field of chemical synthesis, can solve the problems that the sodium azulene sulfonate has not been retrieved, and the research on the preparation of sodium azulene sulfonate crystal hydrate is still blank, etc., and achieves the effect of reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The synthetic method of sodium azulene sulfonate monohydrate is shown in the following equation:

[0046]

[0047] Add 20g of sodium azulene sulfonate to a 500ml three-necked flask, add 200ml of water and stir for 30 minutes, raise the internal temperature to 85°C and reflux for 2 hours. After reflux for 2 hours, place the system in an ice bath and continue stirring for 2 hours. crystal.

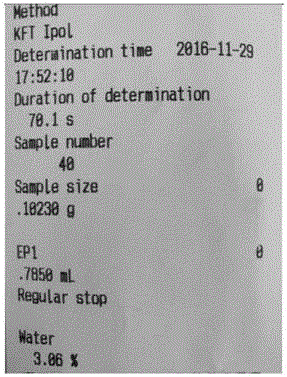

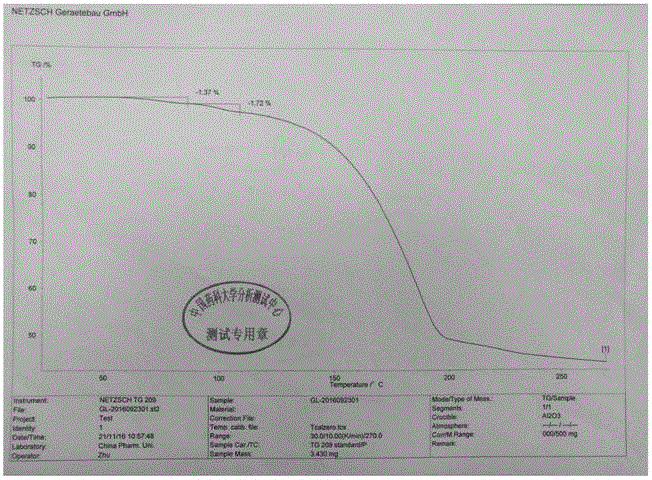

[0048] The precipitated crystals were suction-filtered with a Buchner funnel, washed twice with 150 ml of water, and suction-filtered, and the filter cake was vacuum-dried at 35°C to constant weight to obtain 14 g of sodium azulenesulfonate hemihydrate. Dry to constant weight, and detect moisture content with Karl Fischer moisture analyzer to be 3.06%, the result is as follows: figure 1 As shown, the TG test results are as follows figure 2 shown.

[0049] Add 14g sodium azulene sulfonate hemihydrate into a 500mL three-necked flask, add a mixed solution of 70mL water and 70mL pe...

Embodiment 2

[0056] The preparation method of sodium azulene sulfonate hemihydrate is the same as in Example 1.

[0057]10 g of sodium azulene sulfonate hemihydrate obtained after recrystallization was added to a water / dichloromethane mixed solvent with a volume ratio of 1:1, and fully stirred. The volume of water used was about 5% of the mass of sodium azulene sulfonate hemihydrate. times, after the crystal color changed from blue-black to blue, suction filtration, washing, and drying gave 11.3 g of sodium azulene sulfonate monohydrate with a yield of 91%.

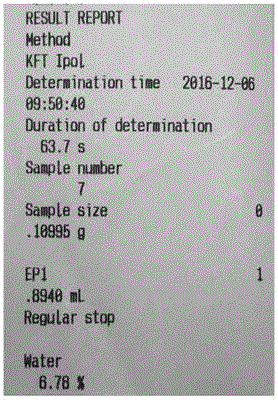

[0058] Dried to constant weight, and tested the moisture result with a Karl Fischer moisture analyzer, the moisture content was 7.21%.

Embodiment 3

[0060] The preparation method of sodium azulene sulfonate hemihydrate is the same as in Example 1.

[0061] 10 g of sodium azulene sulfonate hemihydrate obtained after recrystallization was added to a water / ethyl acetate mixed solvent with a volume ratio of 1:1, and fully stirred. The volume of water used was about 5% of the mass of sodium azulene sulfonate hemihydrate. times, after the crystal color changed from blue-black to blue, filter with suction, wash and dry to obtain 5.2 g of sodium azulenesulfonate monohydrate with a yield of 51%.

[0062] Dry it to constant weight, and check the moisture result with a Karl Fischer moisture analyzer, and the moisture content is 7.33%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com