Production method of high-yield thioglycolic acid

A technology of thioglycolic acid and production method, applied in the production field of high-yield thioglycolic acid, can solve problems such as difficulty in handling electrolyte, increased cost, low yield, etc., and achieves inhibiting thioglycolic acid oxidation reaction, improving yield, and reducing side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

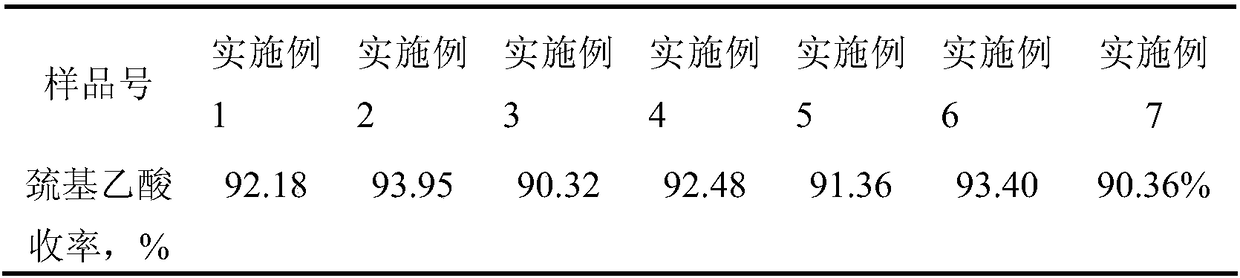

Examples

Embodiment 1

[0029] The method for producing high-yield thioglycolic acid by the sodium hydrosulfide method is formed by reacting the following mass parts of synthetic liquid and reducing agent: 200 parts of synthetic liquid, 9 parts of sodium sulfite, and 40 parts of water.

[0030] Among them, the synthetic liquid is a mixture of sodium chloroacetate and sodium hydrosulfide with a molar ratio of 1:1.1.

[0031] The mass concentration of sodium chloroacetate is 50%, and the mass concentration of sodium hydrosulfide is 27%.

[0032] The production method includes the following steps:

[0033] (1) Add 9.0 parts of sodium sulfite to 40 parts of water and stir to dissolve;

[0034] (2) Add the solution obtained in step (1) to the reactor together with 200 parts of synthetic liquid;

[0035] (3) React at 68°C for 16 minutes, and then lower the temperature to 45°C;

[0036] (4) Acidify with 30.0% hydrochloric acid to a pH of 1.1 to obtain an aqueous solution of thioglycolic acid;

[0037] (5) Extract with i...

Embodiment 2

[0039] The method for producing high-yield thioglycolic acid by the sodium hydrosulfide method is formed by reacting the following mass parts of synthetic liquid and reducing agent: 220 parts of synthetic liquid, 4.0 parts of sodium borohydride, and 23.0 parts of water

[0040] Among them, the synthetic liquid is a mixed liquid composed of sodium chloroacetate and sodium hydrosulfide at a molar ratio of 1:1.2, the mass concentration of sodium chloroacetate is 50%, and the mass concentration of sodium hydrosulfide is 27%.

[0041] The production method includes the following steps:

[0042] (1) Add 4.0 parts of sodium borohydride to 23.0 parts of water and stir to dissolve;

[0043] The processing method includes the following steps:

[0044] (2) Add the solution obtained in step (1) to the reactor together with 220 parts of synthetic liquid;

[0045] (3) React at 70°C for 17 minutes, then lower the temperature to 45°C;

[0046] (4) Acidify with 29.0% hydrochloric acid to a pH of 1.1 to ob...

Embodiment 3

[0049] The method for producing high-yield thioglycolic acid by the sodium hydrosulfide method is formed by reacting the following mass parts of synthetic liquid and reducing agent: 250 parts of bottom liquid, 2.0 parts of ascorbic acid + 3.0 parts of sodium sulfite, and 30.0 parts of water.

[0050] Among them, the synthetic liquid is a mixed liquid composed of sodium chloroacetate and sodium hydrosulfide at a molar ratio of 1:1.3, the mass concentration of sodium chloroacetate is 50%, and the mass concentration of sodium hydrosulfide is 27%.

[0051] The processing method includes the following steps:

[0052] (1) Add 2.0 parts of ascorbic acid + 3.0 parts of sodium sulfite to 23.0 parts of water and stir to dissolve;

[0053] (2) Add the solution obtained in step (1) to the reactor together with 250 parts of synthetic liquid;

[0054] (3) React at 72°C for 15 minutes, then lower the temperature to 45°C;

[0055] (4) Acidify with 29.0% hydrochloric acid to a pH of 1.3 to obtain an aque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com