Device and method for preparing 1,3,5-trioxane continuously from concentrated formaldehyde as raw material

A technology of trioxymethylene and concentrated formaldehyde, applied in the direction of organic chemistry, can solve problems such as environmental pollution, and achieve the effects of eliminating pollution, reducing energy consumption and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

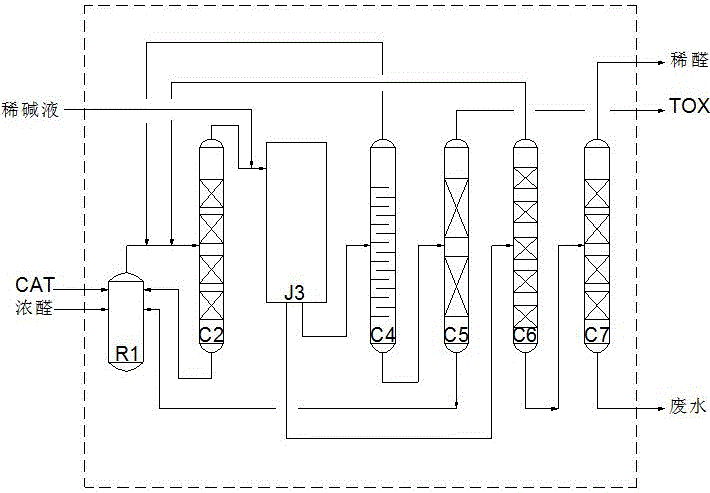

[0019] Such as figure 1 As shown (only the main equipment is drawn, other instruments, pumps, valves, intermediate tanks and other equipment have been omitted, and the structural representation will not affect the understanding and implementation of those skilled in the art), a kind of concentrated formaldehyde is used as raw material to continuously prepare trimer Formaldehyde plant, including reaction and concentration system, crystallization system and refining system.

[0020] Described reaction and enrichment system comprise paraformaldehyde reactor R1, concentration tower C2; The top outlet of paraformaldehyde reactor R1 links to each other with the central feed port of concentration tower C2, and concentration tower C2 tower top output outlet is connected with The feed port of the crystallization system J3 is connected, and the extraction outlet of the tower still of the concentration tower C2 is connected with the middle part reflux port of the paraformaldehyde reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com