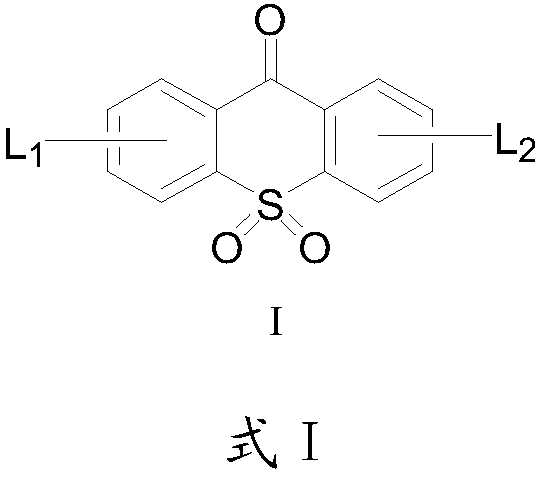

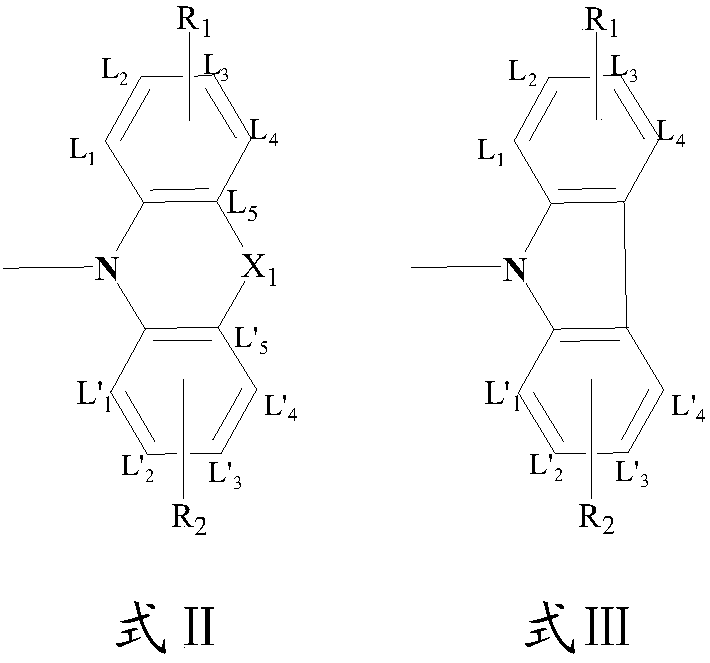

A compound based on oxidized thioxanthone, preparation method and application thereof

A technology for oxidizing thioxanthone and compounds, which is applied in the fields of chemical instruments and methods, organic chemistry, semiconductor/solid-state device manufacturing, etc., can solve different problems and achieve the goals of avoiding aggregation, improving thermal stability, and good photoelectric properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Compound 1

[0051]

[0052] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-10,10-dioxo-10H-thianthracene-9-one, 0.015mol compound M1, 0.03mol sodium tert-butoxide, 1× 10 -4 molPd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150mL toluene, heated and refluxed for 24 hours, sampled and spotted, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 98.90% and a yield of 50.9%.

[0053] HPLC-MS, molecular formula C 34 h 23 NO 4 S, theoretical value: 541.13, test value: 541.43.

Embodiment 2

[0054] Example 2 Compound 8

[0055]

[0056] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 3-bromo-10,10-dioxo-10H-thianthracene-9-one, 0.015mol compound M2, 0.03mol sodium tert-butoxide, 1× 10 -4 molPd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150mL toluene, heated to reflux for 24 hours, sampled and spotted, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 99.80% and a yield of 47%.

[0057] HPLC-MS, molecular formula C 40 h 28 N 2 o 3 S, theoretical value: 616.18, test value: 616.28.

Embodiment 3

[0058] Example 3 Compound 16

[0059]

[0060] In a 250mL three-neck flask, under a nitrogen atmosphere, add 0.01mol 2-bromo-10,10-dioxo-10H-thianthracene-9-one, 0.011mol compound M3, 0.03mol sodium tert-butoxide, 1× 10 -4 molPd 2 (dba) 3 , 1×10 -4 mol tri-tert-butylphosphine, 150mL toluene, heated to reflux for 24 hours, sampled and spotted, cooled naturally, filtered, the filtrate was rotary evaporated, and passed through a silica gel column to obtain the target product with a purity of 99.10% and a yield of 56%.

[0061] HPLC-MS, molecular formula C 36 h 25 NO 3 S, theoretical value: 551.16, test value: 551.19.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com