Yellow tang sulfated polysaccharide as well as preparation method and application thereof

A technology of Ascophyllum nodosum sulfate ester and polysaccharide, which is applied in the field of polysaccharides, can solve the problems of less research on Ascophyllum nodosum polysaccharide, and achieve the effect of large molecular weight, stable active structure and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

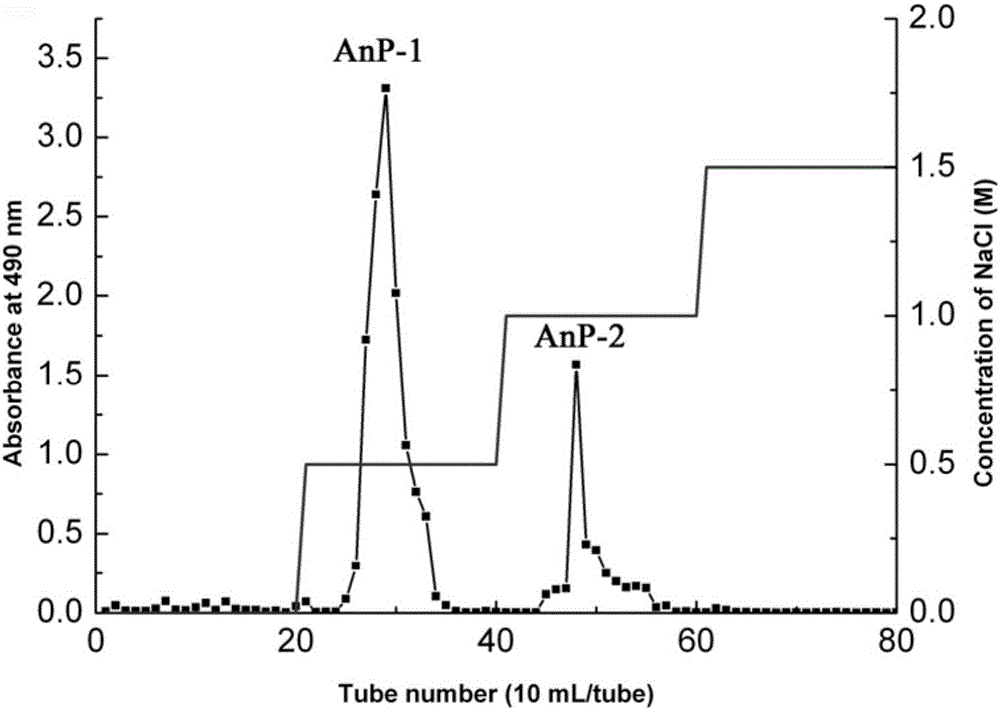

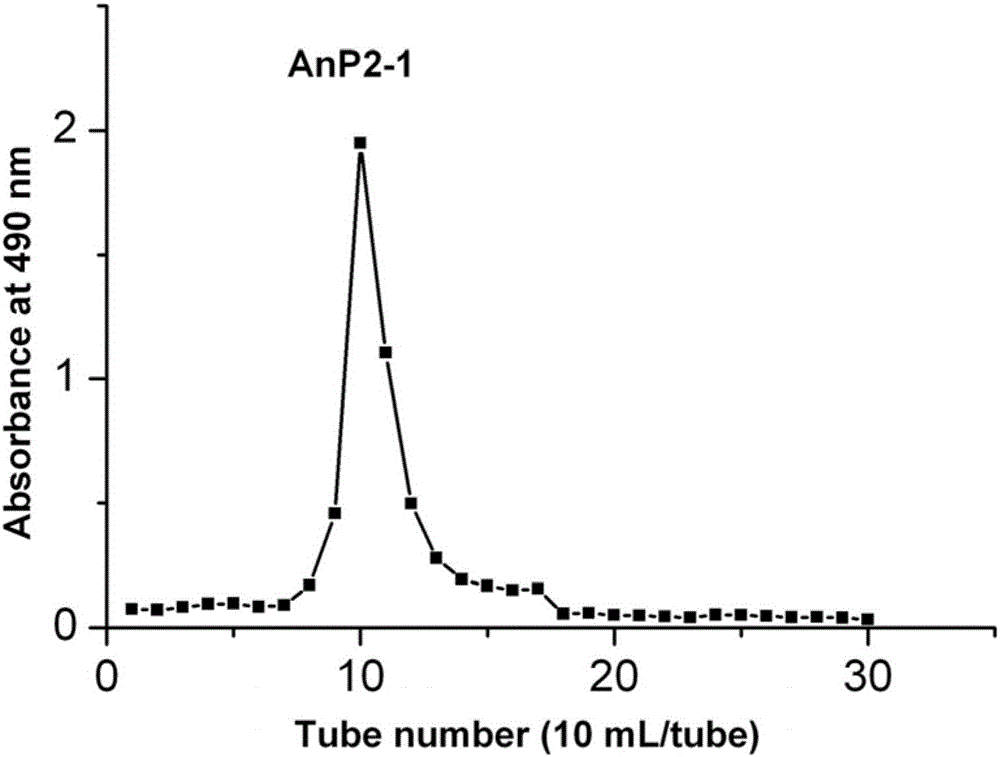

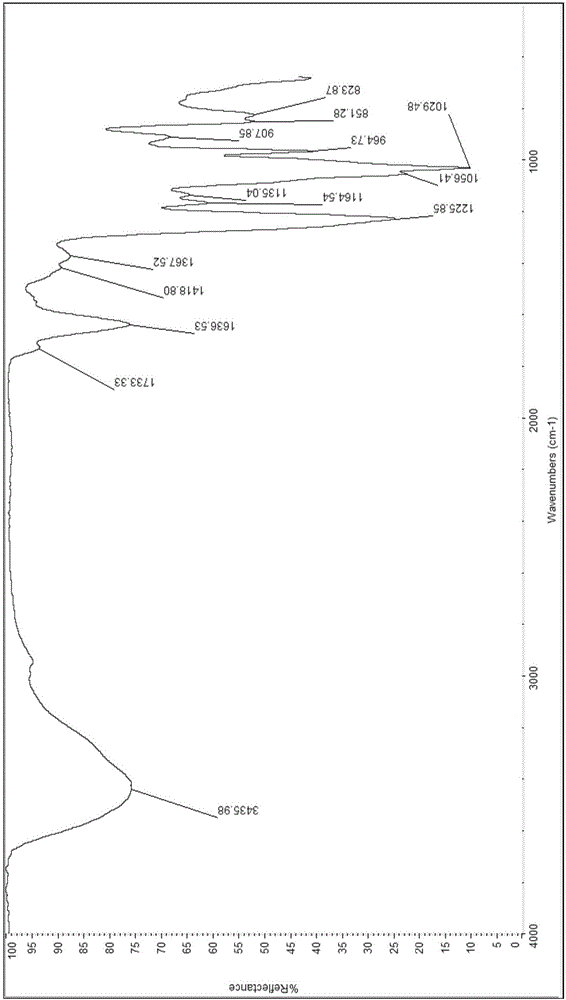

Image

Examples

Embodiment 1

[0055] A kind of preparation method of Ascophyllum nodosum sulfated polysaccharide provided in this embodiment, it comprises:

[0056] The Ascophyllum nodosum sample was crushed through a 60-mesh sieve, soaked in 80% ethanol and dried in the air, and repeated several times to remove pigments, polyphenols, monosaccharides and oligosaccharides.

[0057] Extract the impurity-removed Ascophyllum nodosum in water at 60-100°C with a liquid-to-solid ratio of 20mL / g for 3 times, each time for 4 hours, centrifuge, combine the extracts for three times, and concentrate to obtain a water extract.

[0058] Add absolute ethanol to the water extract for alcohol precipitation, and control the ethanol concentration in the alcohol precipitation system to 70%, overnight at 4°C, centrifuge, and collect the precipitate to obtain the precipitate.

[0059] Redissolve the precipitate in pure water, put the sample into a dialysis bag with a cutoff of 8000-14000Da for dialysis for 5 days, then concentr...

Embodiment 2

[0063] A kind of preparation method of Ascophyllum nodosum sulfated polysaccharide provided in this embodiment, it comprises:

[0064] The Ascophyllum nodosum sample was crushed through a 60-mesh sieve, soaked in 70% ethanol and dried in the air, and repeated several times to remove pigments, polyphenols, monosaccharides and oligosaccharides.

[0065] Extract the impurity-removed Ascophyllum nodosum in water at 60-100°C with a liquid-to-solid ratio of 5mL / g for 4 times, each time for 5h, centrifuge, combine the four extracts, and concentrate to obtain the water extract.

[0066] Add absolute ethanol to the water extract for alcohol precipitation, and control the ethanol concentration in the alcohol precipitation system to 60%, overnight at 1°C, centrifuge, and collect the precipitate to obtain the precipitate.

[0067] The precipitate was redissolved in pure water, and the sample was put into a dialysis bag with a cutoff of 8000-14000Da for dialysis for 3 days, then concentrat...

Embodiment 3

[0071] A kind of preparation method of Ascophyllum nodosum sulfated polysaccharide provided in this embodiment, it comprises:

[0072] After the Ascophyllum nodosum sample was crushed through an 80-mesh sieve, it was soaked in 90% ethanol and dried in the air, and repeated several times to remove pigments, polyphenols, monosaccharides and oligosaccharides.

[0073] Extract the impurity-removed Ascophyllum nodosum in water at 60-100°C with a liquid-to-material ratio of 30mL / g, extract twice for 3 hours each time, combine the two extracts after centrifugation, and concentrate to obtain a water extract.

[0074] Add absolute ethanol to the water extract for alcohol precipitation, and control the ethanol concentration in the alcohol precipitation system to 80%, overnight at 8°C, centrifuge, and collect the precipitate to obtain the precipitate.

[0075] The precipitate was redissolved in pure water, and the sample was put into a dialysis bag with a cutoff of 8000-14000 Da for dial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com