Preparation method for polyacrylic acid water-absorbent resin

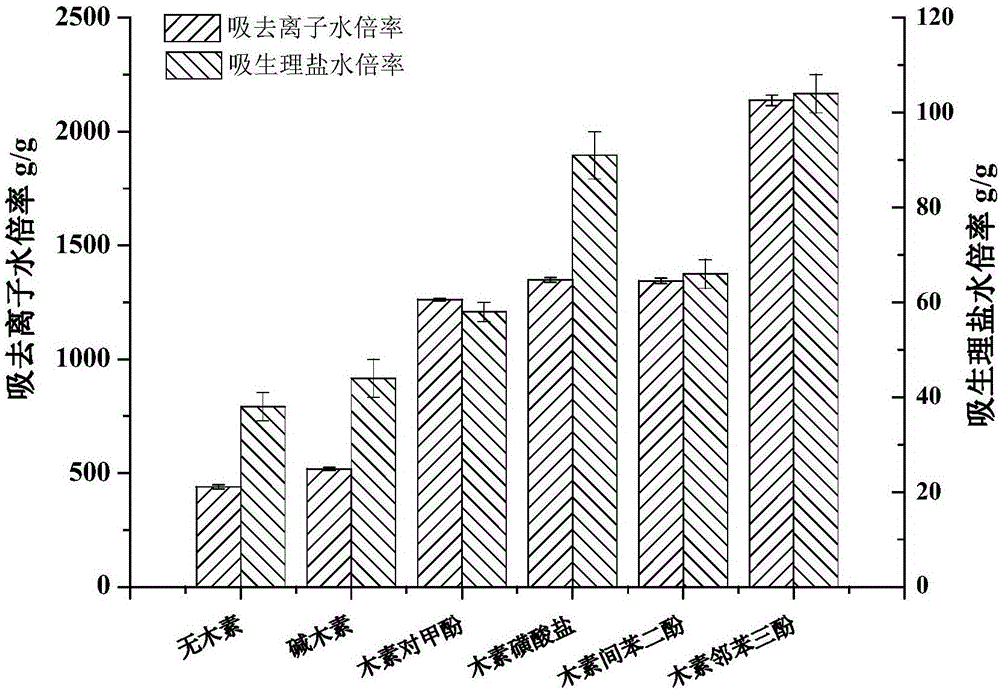

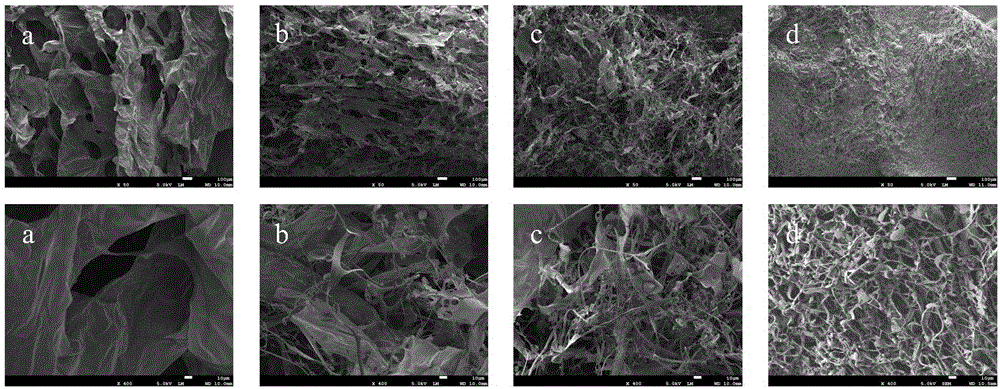

A technology of water-absorbing resin and polypropylene, which is applied in the field of changing the pore structure and water-absorbing capacity of polyacrylic acid-based water-absorbing resins. It can solve the problems of waste of resources and incomplete development and utilization of aromatic ring polymers, and achieve the effect of improving water-absorbing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: preparation process of sodium polyacrylate resin

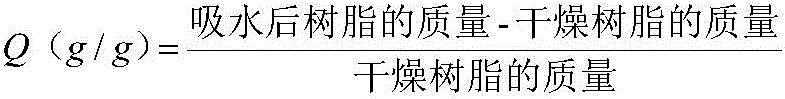

[0032] Accurately weigh 18.75g of acrylic acid in a 100mL beaker, slowly titrate acrylic acid with a 15.25w% aqueous solution prepared by dissolving 6.66g NaOH in 37mL deionized water under an ice-water bath to prepare a 65% sodium acrylate aqueous solution with a neutralization degree of 20mL The sodium acrylate solution configured above was stirred evenly and then transferred to a four-necked flask equipped with a nitrogen interface, a mechanical stirrer, a reflux condenser, and a thermometer, and reacted at 60°C under the protection of a nitrogen environment. After reaching the reaction temperature, add 0.0800g over Potassium sulfate, 0.0060 g of N'N-methylenebisacrylamide was added after 30 minutes, during which time the sodium acrylate solution was added dropwise. After reacting for 60 minutes, the reaction solution had a certain viscosity, poured it into a 200mL beaker filled with 100mL of ethanol, s...

Embodiment 2

[0033] Embodiment 2: the resin preparation process of alkali lignin grafting sodium polyacrylate

[0034]Accurately weigh 18.75g of acrylic acid in a 100mL beaker, slowly titrate acrylic acid with a 15.25w% aqueous solution prepared by dissolving 6.66g NaOH in 37mL deionized water under an ice-water bath to prepare a 65% sodium acrylate aqueous solution with a neutralization degree of 0.50 The alkali lignin in kraft pulping black liquor and 20mL of the above-mentioned sodium acrylate solution were stirred evenly, and then transferred to a four-necked flask equipped with a nitrogen interface, a mechanical stirrer, a reflux condenser, and a thermometer. React at 60°C under protection, add 0.0800g potassium persulfate after reaching the reaction temperature, and add 0.0060g N'N-methylenebisacrylamide after 30 minutes, during which time the sodium acrylate solution is added dropwise. After a total reaction time of 60 minutes, the reaction solution has a certain viscosity, pour it ...

Embodiment 3

[0035] Embodiment 3: Process of preparing resin by grafting lignin p-cresol with sodium polyacrylate

[0036] Accurately weigh 18.75g of acrylic acid in a 100mL beaker, slowly titrate acrylic acid with a 15.25w% aqueous solution prepared by dissolving 6.66g NaOH in 37mL deionized water under an ice-water bath to prepare a 65% sodium acrylate aqueous solution with a neutralization degree of 0.50 g of lignin p-cresol and 20mL of the sodium acrylate solution configured above were stirred evenly, then transferred to a four-necked flask equipped with a nitrogen port, a mechanical stirrer, a reflux condenser, and a thermometer, and reacted at 60°C under nitrogen protection. After reaching the reaction temperature, 0.0800g potassium persulfate was added, and 0.0060g N'N-methylenebisacrylamide was added after 15 minutes, during which the remaining sodium acrylate solution was added dropwise. After a total reaction time of 30 minutes, the reaction solution has a certain viscosity, pour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com