Polymer photonic crystal microsphere, and preparation method and application thereof

A technology for photonic crystal microspheres and polymers, which is applied in the measurement of color/spectral properties, etc., can solve the problems of long preparation period, large angle dependence, and single response of photonic crystals, and achieves pure color, good repeatability, and system simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

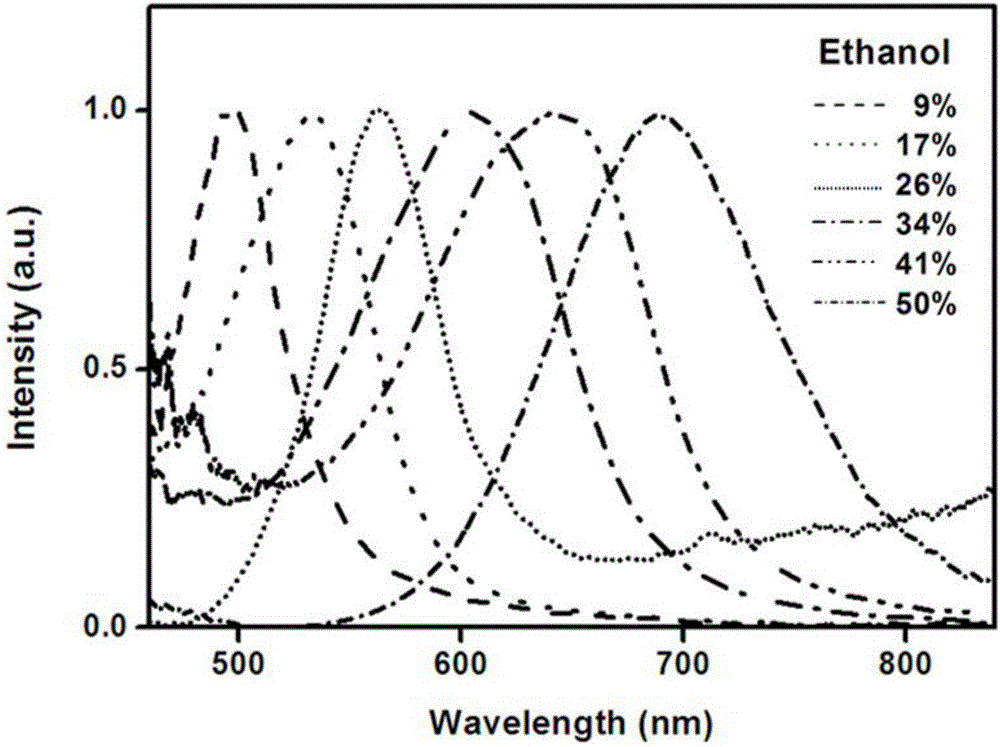

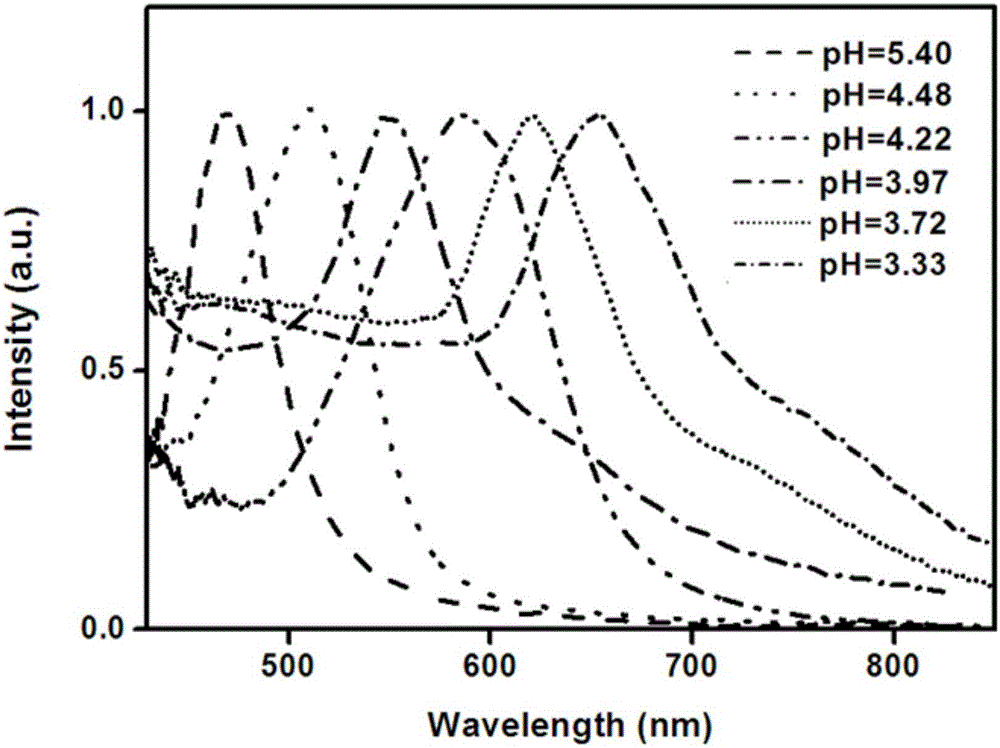

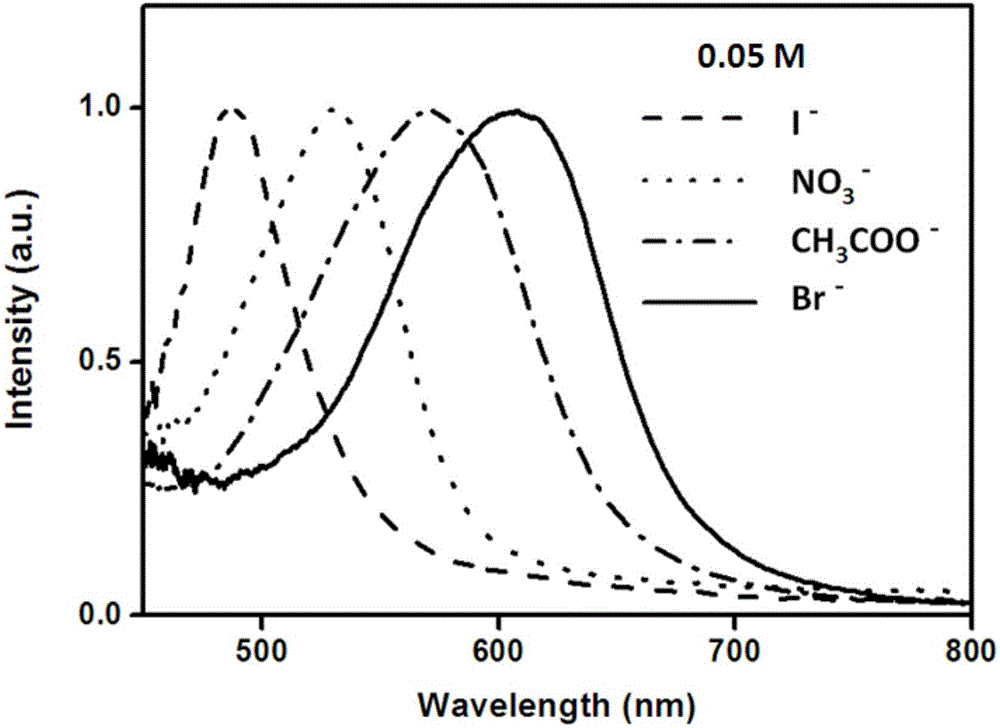

[0055] The polymer photonic crystal microspheres provided by the present invention have a single color. In buffer solutions of different pH values, different ions or specific organic solvents of different concentrations, the reflected light wavelength shifts greatly, showing a reflection mode microscope Visible color changes. The preparation method of polymer photonic crystal microspheres provided by the present invention includes the following steps:

[0056] (1) Preparation of solution: fully dissolve the block copolymer PS-b-P2VP in an organic solvent (such as chloroform) to obtain the dispersed phase of the microfluidic system; dissolve the surfactant polyvinyl alcohol (PVA) in the Ionized water to obtain the continuous phase of the microfluidic system; dissolve the surfactant cetyltrimethylammonium bromide (CTAB) in deionized water to obtain the annealing external environment solution; the dispersed phase of the PS-b-P2VP solution The concentration is 1-15 mg / mL, the contin...

Embodiment 1

[0071] The polymer photonic crystal microspheres in this embodiment were prepared as follows:

[0072] (1) Preparation of the required solution: fully dissolve the block copolymer PS-b-P2VP in an organic solvent to obtain the dispersed phase of the microfluidic system; dissolve the surfactant PVA in deionized water to obtain the microfluidic The continuous phase of the system; dissolve the surfactant CTAB in deionized water to obtain an annealing external environment solution; the concentration of the dispersed phase PS-b-P2VP solution is 1 mg / mL, and the continuous phase PVA solution is 0.5 mg / mL, annealing The concentration of CTAB solution in the external environment is 5 mg / mL.

[0073] (2) Preparation of microfluidic chip: the chip includes inner tubes 1 and 2, outer tube and outer tube sampling head; two inner tubes and outer tube are sleeved with a common central axis; one end of inner tube 1 is pointed and extends into the outer tube The inside of the tube to the center, t...

Embodiment 2

[0077] The polymer photonic crystal microspheres in this embodiment were prepared as follows:

[0078] (1) Preparation of the required solution: fully dissolve the block copolymer PS-b-P2VP in an organic solvent to obtain the dispersed phase of the microfluidic system; dissolve the surfactant PVA in deionized water to obtain the microfluidic The continuous phase of the system; dissolve the surfactant CTAB in deionized water to obtain the annealing external environment solution; each milliliter of dispersed phase solution contains 5mg of PS-b-P2VP, each milliliter of continuous phase solution contains 3mg of PVA, and each milliliter of annealing external environment solution contains CTAB 3mg.

[0079] (2) Preparation of microfluidic chip: the chip includes inner tubes 1 and 2, outer tube and outer tube sampling head; two inner tubes and outer tube are sleeved with a common central axis; one end of inner tube 1 is pointed and extends into the outer tube From the inside to the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com