High-surface glossiness and high-dimensional stability polyamide composite material and preparation method thereof

A composite material and polyamide technology, which is applied in the field of polyamide composite materials with high surface gloss and high dimensional stability and its preparation, can solve the problems of less research on dimensional stability, reduced mechanical properties, poor dimensional stability, etc., to achieve Excellent chemical resistance, maintaining dimensional stability, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

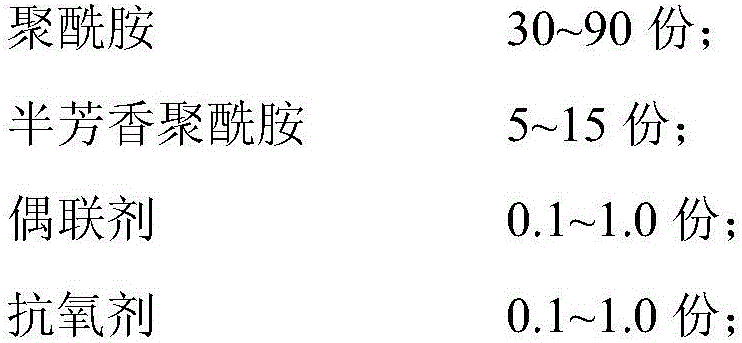

[0045] The preparation method of polyamide of the present invention comprises the following steps:

[0046] (1) uniformly mixing polyamide, semi-aromatic polyamide, antioxidant, heat-resistant agent, lubricant, and fluidity improver to prepare a mixed material;

[0047] (2) Spray the coupling agent in the filler and mix evenly to obtain the mixed material;

[0048] (3) Add the material obtained in step (1), the material obtained in step (2) and glass fiber from different material ports, melt extrude, and granulate to obtain the polyamide composite material.

[0049] Preferably, the mixing in step (1) is carried out in a high-speed mixer, and the mixing time is 1 to 5 minutes.

[0050] The specific implementation of step (2) is as follows: add the filler into a high-speed mixer at a temperature of 75 ° C, then add the coupling agent to the filler in a spraying manner, and mix for 10 to 20 minutes to ensure coupling The agent is evenly coated on the filler surface.

[0051] T...

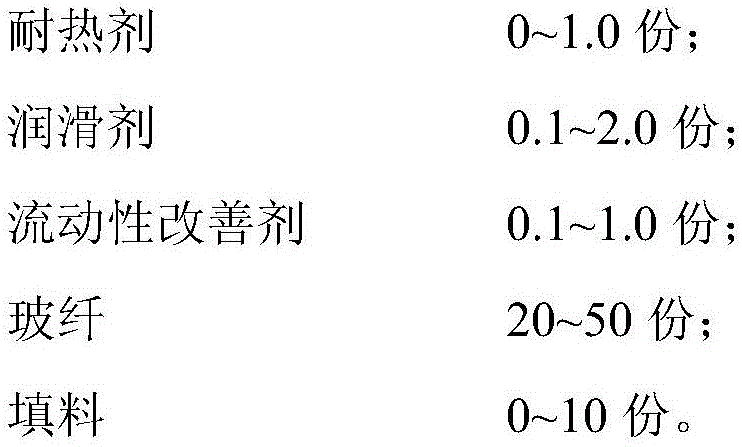

Embodiment 1

[0055] The polyamide composite material is made of the raw materials of the following weight fractions: PA66 is 71.6 parts, polyhexamethylene isophthalamide is 5 parts, silane coupling agent is 0.1 part, antioxidant is 0.2 part, heat-resistant agent 0.5 parts, 0.3 parts lubricant, 0.3 parts fluidity improver, 30 parts glass fiber, 2 parts mica; the manufacturing process is: the temperature of the first zone is 180°C, the temperature of the second zone is 220°C, the temperature of the third zone is 230°C, The temperature in the fourth zone is 240°C, the temperature in the fifth zone is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 230°C, the temperature in the eighth zone is 220°C, and the temperature in the ninth zone is 240°C.

Embodiment 2

[0057] The polyamide composite material is made of the following raw materials in weight fractions: PA66 is 56.5 parts, polyhexamethylene isophthalamide is 10 parts, silane coupling agent is 0.1 part, antioxidant is 0.2 part, heat-resistant agent 0.5 parts, 0.3 parts lubricant, 0.3 parts fluidity improver, 30 parts glass fiber, 2 parts mica; the manufacturing process is: the temperature of the first zone is 180°C, the temperature of the second zone is 220°C, the temperature of the third zone is 230°C, The temperature in the fourth zone is 250°C, the temperature in the fifth zone is 250°C, the temperature in the sixth zone is 220°C, the temperature in the seventh zone is 210°C, the temperature in the eighth zone is 200°C, and the temperature in the ninth zone is 250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com