Preparation and application of an environmentally friendly insulating coating solution for oriented silicon steel

A technology of oriented silicon steel and insulating coating, applied in coatings, anti-corrosion coatings, etc., can solve the problems of iron core processing easy to generate dust, pollute the environment, waste liquid treatment, pollute the environment, etc., to solve the problem of easy generation of small holes and powder , good appearance, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] For example, the following preparation steps can be used to prepare the silica sol of the present invention: 120 to 180 parts of silicon powder (purity is 95%, particle size is 200 mesh) is soaked in hot water at 65 ° C for 2 hours to activate it to remove its surface The inert film was then dried to keep it at 65°C. Heat 50-80 parts of water glass (modulus 2.4), 3-6 parts of ammonia water (25% by weight) and 1000 parts of deionized water to 90°C under stirring, and then add dried 120-180 Part silicon powder, control the temperature to be constant, cool down after reacting for 5 hours. Use a vacuum filter to remove unreacted silicon powder, add 3 to 6 parts of γ-glycidyl etheroxypropyltrimethoxysilane (KH560) to modify the surface of the silica sol, and add sodium hydroxide to adjust the pH The value is 9-10, and the silica sol described in the present invention is obtained. Preferably, the silicon powder is 160 parts, the water glass is 60 parts, the ammonia water is...

Embodiment 1

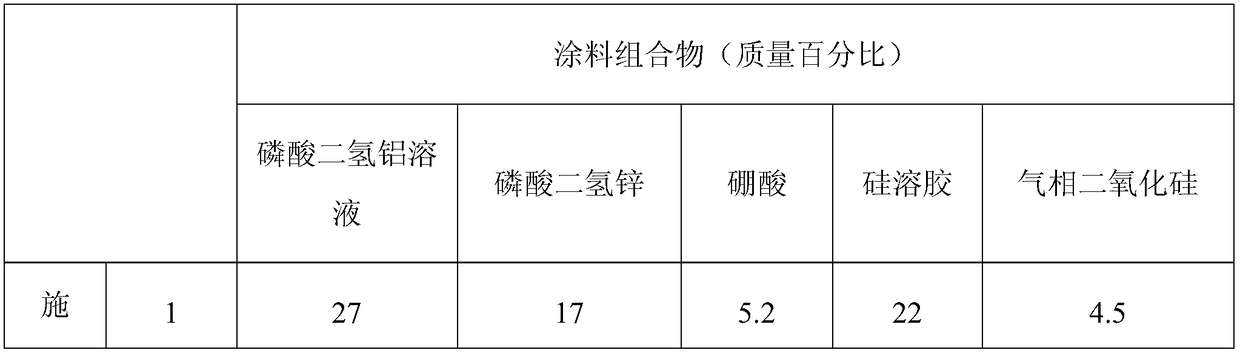

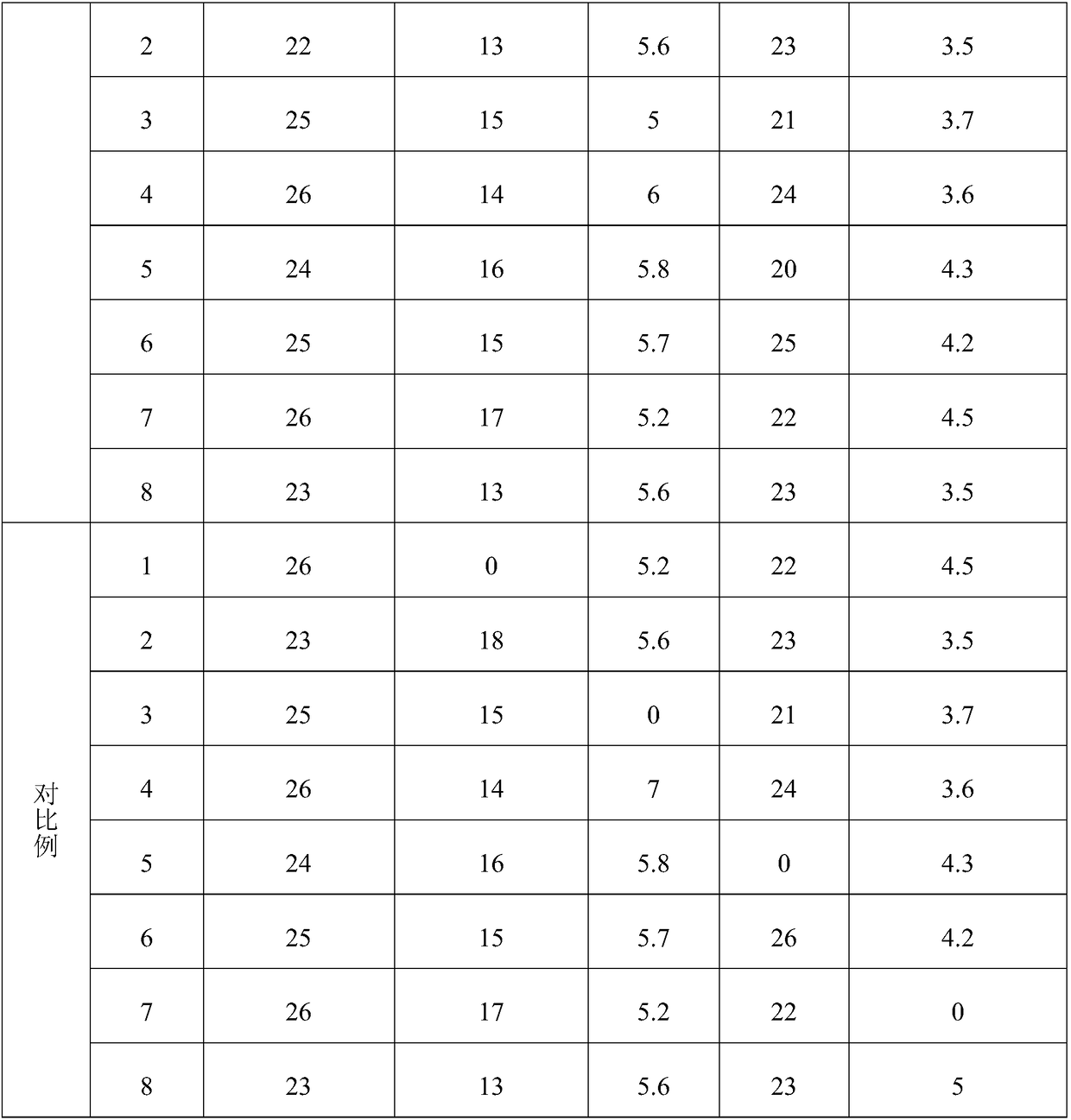

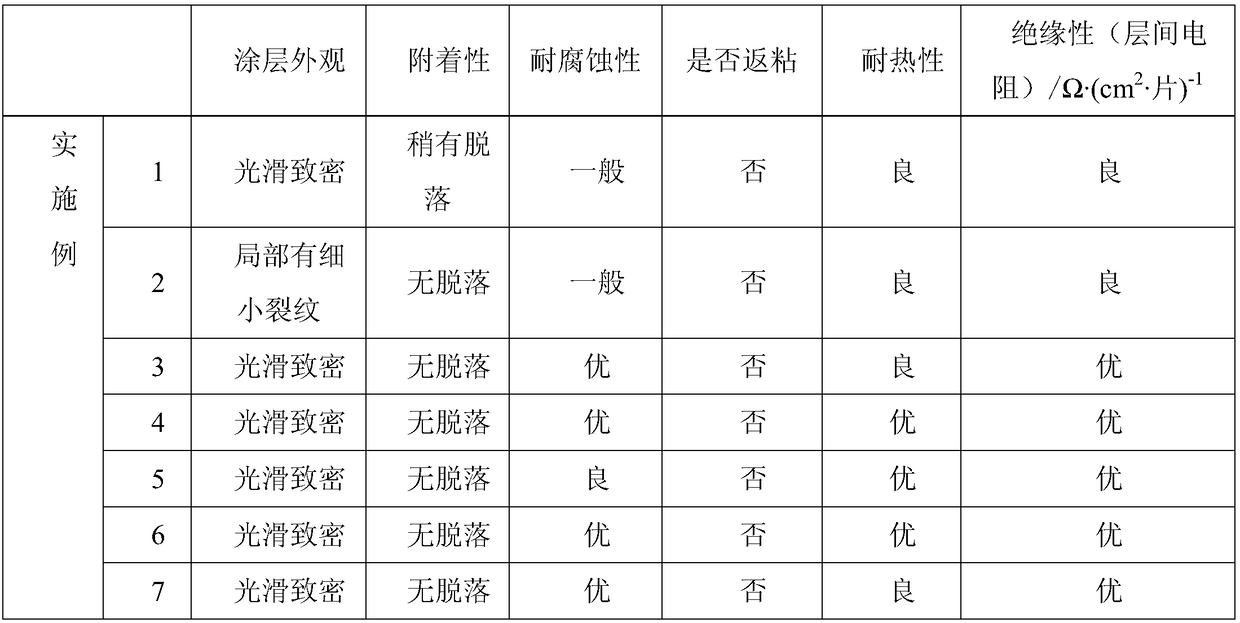

[0047] The environmentally friendly insulating coating solution prepared according to the formula shown in Table 1 is used to coat the oriented silicon steel. After coating, the temperature is raised at 50°C / s, dried at 320°C for 20s, and then sintered at 850°C. The duration is 30 seconds, and finally an insulating coating of 2-3 μm can be formed on the surface of the grain-oriented silicon steel.

[0048] The specific preparation steps are as follows: according to the formula ratio in Table 1, the aluminum dihydrogen phosphate solution, the zinc dihydrogen phosphate solid and deionized water are first added to the reaction vessel and stirred, and the solid boric acid is added while stirring after the zinc dihydrogen phosphate solid is completely dissolved. After the boric acid is completely dissolved, add silica sol and stir evenly, then move the above homogeneous solution to a high-speed mixer, and uniformly disperse the fumed silica solid in it at a speed of 800 rpm to final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com