Oxidation-resistant corrosion-resistant additive for preparing protective paint for underground metallic pipeline

A technology for protective coatings and metal pipes, applied in anti-corrosion coatings and other directions, can solve the problems of easy oxidation and corrosion, shorten service life, surface rust, etc., achieve excellent oxidation resistance and corrosion resistance, prolong service life, and enhance resistance to corrosion. The effect of oxidation and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 3 parts of polyvinyl chloride paste resin and 3 parts of ethylene-vinyl acetate copolymer to 20 parts of PTFE superfine powder, and heat up to 130-135 ° C at a heating rate of 5 ° C / min and mix for 20 min , then add 1 part of vulcanized lard, 0.5 part of glass fiber powder and 0.3 part of nano-zinc oxide, continue to mix at 130-135 ° C for 10 minutes, and then naturally cool to room temperature to obtain material I;

[0025] (2) Add 3 parts of polyethylene terephthalate and 2 parts of rubber powder to 5 parts of rosin-modified phenolic resin, heat up to 100-105 °C at a heating rate of 5 °C / min and mix for 15 minutes, then add 0.5 parts of sepiolite fibers and 0.2 parts of N-methylpyrrolidone, continue to heat up to 125-130°C at a heating rate of 5°C / min and mix for 15 minutes, then naturally cool to room temperature to obtain material II;

[0026] (3) Add material II, 1 part of polydimethyldiallyl ammonium chloride, 0.3 part of ferrous sulfate and 0.2 part of ...

Embodiment 2

[0031] (1) Add 3 parts of polyvinyl chloride paste resin and 2 parts of ethylene-vinyl acetate copolymer to 20 parts of PTFE superfine powder, and heat up to 130-135 °C at a heating rate of 5 °C / min and mix for 20 minutes , then add 1 part of vulcanized lard, 0.5 part of glass fiber powder and 0.5 part of nano-zinc oxide, continue to mix at 130-135 ° C for 10 minutes, and then naturally cool to room temperature to obtain material I;

[0032] (2) Add 3 parts of polyethylene terephthalate and 2 parts of rubber powder to 8 parts of rosin-modified phenolic resin, heat up to 100-105°C at a heating rate of 5°C / min and mix for 15 minutes, then add 0.5 parts of sepiolite fibers and 0.3 parts of N-methylpyrrolidone, continue to heat up to 125-130°C at a heating rate of 5°C / min and mix for 15 minutes, then naturally cool to room temperature to obtain material II;

[0033] (3) Add material II, 1 part of polydimethyldiallylammonium chloride, 0.5 part of ferrous sulfate and 0.3 part of 1-b...

Embodiment 3

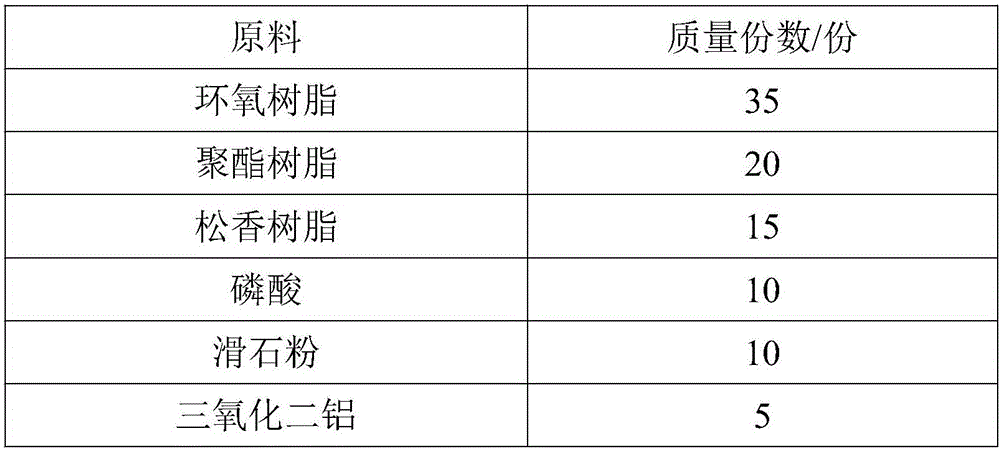

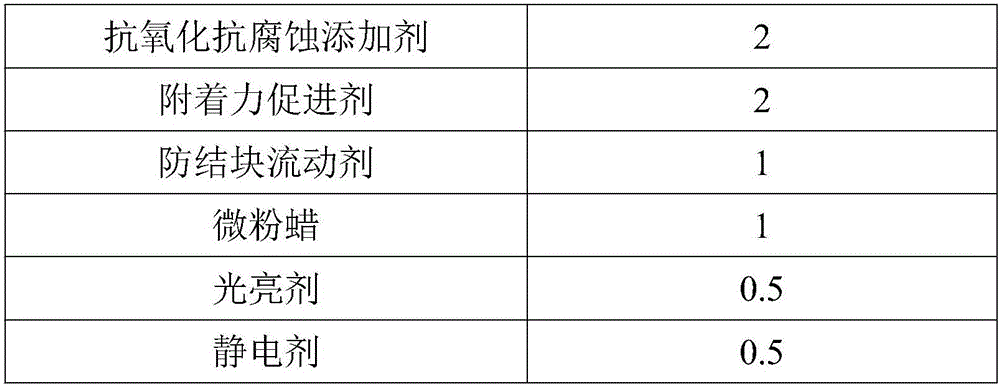

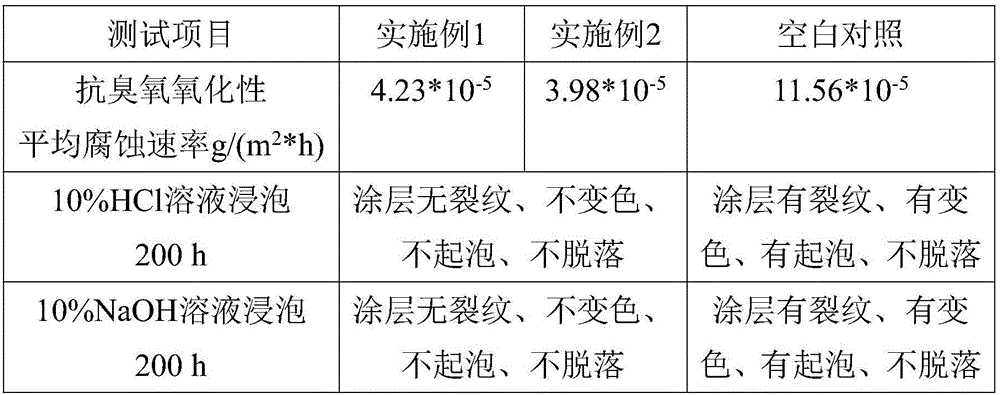

[0038] Add the anti-oxidation and anti-corrosion additives prepared in Example 1 and Example 2 into the raw materials for the preparation of conventional metal pipeline protective coatings according to a certain proportion, and after fully mixing, powder coatings are obtained. The specific raw material composition and proportioning ratio are shown in Table 1. The prepared powder coating was sprayed on the metal pipe, and the anti-oxidation and anti-corrosion performance tests were carried out on the formed coating, and a blank control without adding anti-oxidation and anti-corrosion additives was set. The results are shown in Table 2.

[0039] Table 1 Preparation raw materials and proportions of protective coatings for metal pipelines

[0040]

[0041]

[0042] Table 2 coating oxidation resistance and corrosion resistance test results

[0043]

[0044] Ozone oxidation resistance test conditions: Ozone concentration in the ozone corrosion chamber is 500ppm, temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com