A kind of blueberry fruit dipping wine and preparation method thereof

A blueberry and fruit technology, applied in the field of dipping wine, can solve the problems of reduced content of functional components, failure to participate in preparation, retting odor, etc., and achieve the effect of short dipping time, bright color and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

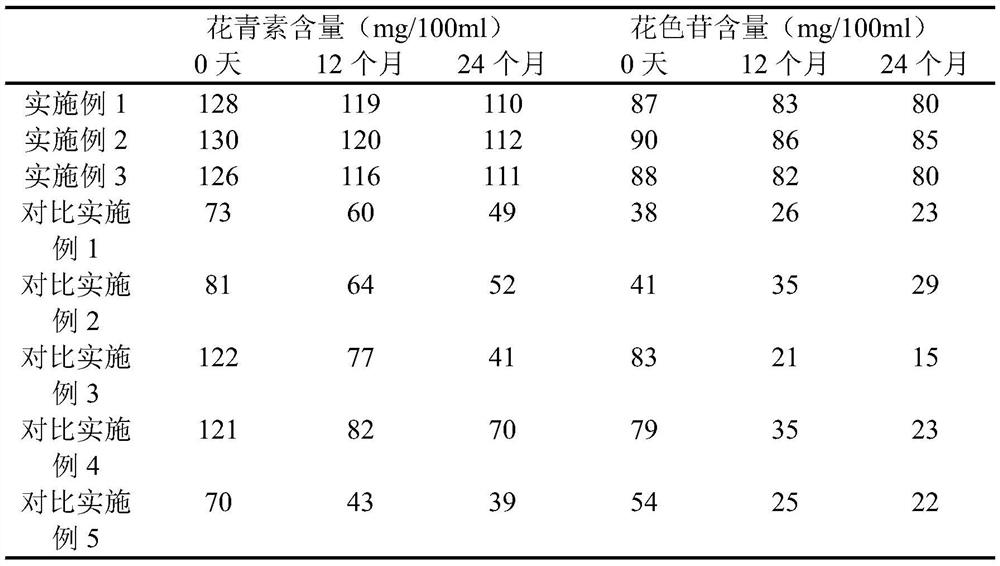

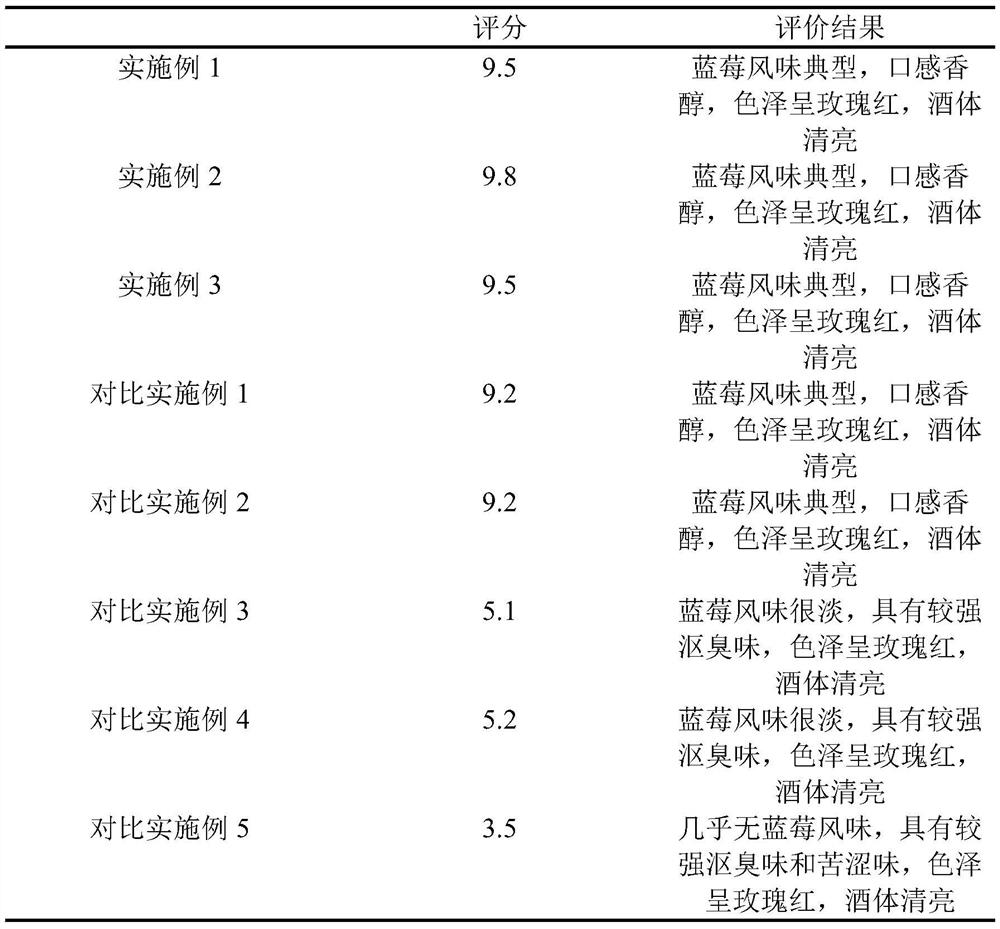

Examples

Embodiment 1

[0034] (1) Carry out pretreatment to blueberry, when carrying out pretreatment to blueberry, remove blueberry fruit stem and leaf, only stay fruit, carry out infrared drying to blueberry fruit and pulverize; When drying, control moisture content to be 13~15%;

[0035] (2) mixing the product of step (1), white wine and acid regulator, and then dipping, wherein the proportion of blueberry fruit (the product of step (1)) and white wine after infrared drying and pulverization is 180g / 1000ml; During maceration, CO is introduced into the brewing vessel 2 and N 2 Mixed gas, the amount of each injection is 3% of the volume of the wine making container, and it is carried out twice in total; CO 2 and N 2 The volume ratio of the acid regulator is 95:5; the acid regulator is malic acid, and the mass ratio of the acid regulator to the blueberry fruit is 1:60; the degree of liquor is 55%vol;

[0036] (3) Filter the product of step (2); clarify for 2 days after filtering;

[0037] (4) Bl...

Embodiment 2

[0039] (1) Carry out pretreatment to blueberry, when carrying out pretreatment to blueberry, remove blueberry fruit stem and leaf, only stay fruit, carry out infrared drying to blueberry fruit and pulverize; When drying, control moisture content to be 8~12%;

[0040] (2) mixing the product of step (1), white wine and acid regulator, and then dipping, wherein the proportion of blueberry fruit (the product of step (1)) and white wine after infrared drying and crushing is 120g / 1000ml; During maceration, CO is introduced into the brewing vessel 2 and N 2 Mixed gas, the amount of each injection is 3% of the volume of the wine making container, for a total of 3 times; CO 2 and N 2 The volume ratio of the acid regulator is 90:10; the acid regulator includes malic acid or citric acid, and the mass ratio of the acid regulator to the blueberry fruit is 1:50; the degree of liquor is 30% vol.

[0041] (3) filtering step (2) gained;

[0042] (4) Blend the product of step (3); when blen...

Embodiment 3

[0044] (1) Carry out pretreatment to blueberry, when carrying out pretreatment to blueberry, remove blueberry fruit stem and leaf, only stay fruit, carry out infrared drying to blueberry fruit and pulverize; When drying, control moisture content to be 5~8%;

[0045] (2) mixing the product of step (1), white wine and acid regulator, and then dipping, wherein the proportion of the blueberry fruit (the product of step (1)) and white wine after infrared drying and crushing is 150g / 1000ml; During maceration, CO is introduced into the brewing vessel 2 and N 2 Mixed gas, the amount of each injection is 3% of the volume of the wine making container, for a total of 3 times; CO 2 and N 2 The volume ratio of the acid regulator is 93:7; the acid regulator is citric acid, and the mass ratio of the acid regulator to the blueberry fruit is 1:55; the degree of liquor is 45%vol;

[0046] (3) filtering step (2) gained;

[0047] (4) Blend the product of step (3); when blending, add rock suga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com