Preparing method of large-scale Ti-Al-Nb series alloy fine grain casting ingot

A large-scale, alloy technology, applied in the field of lightweight high-temperature structural material preparation, can solve problems such as ingot structure coarsening, achieve uniform and fine grains, improve composition uniformity, and solve the effect of coarse microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

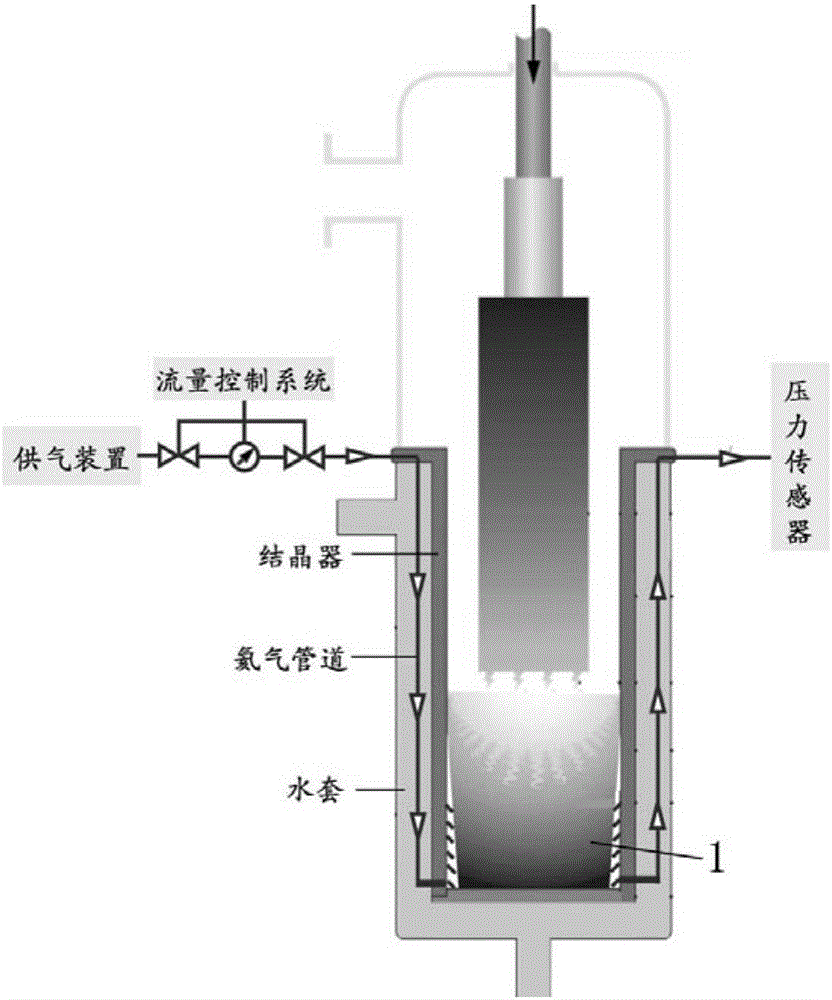

[0019] The embodiment of the present invention provides a method for preparing a large-scale Ti-Al-Nb alloy fine-grained ingot, which is a smelting preparation of a large-scale Ti-Al-Nb intermetallic compound fine-grained ingot with high quality stability The method can realize the smelting preparation of a large-scale Ti-Al-Nb series intermetallic ingot, solve the problem of coarsening the ingot structure, and reduce the segregation tendency of the ingot, including the following steps:

[0020] Step 1. According to the mass percentages of Ti, Al, and Nb in the nominal chemical composition of the Ti-Al-Nb alloy, the raw materials are weighed, and the raw materials are evenly mixed and pressed into several electrode blocks;

[0021] Step 2, welding several electrode blocks made in the step 1 into a consumable electrode in batches;

[0022] Step 3. Carrying out one or more vacuum consumable smelting on the consumable electrode produced in the above step 2 to obtain a semi-finish...

Embodiment 1

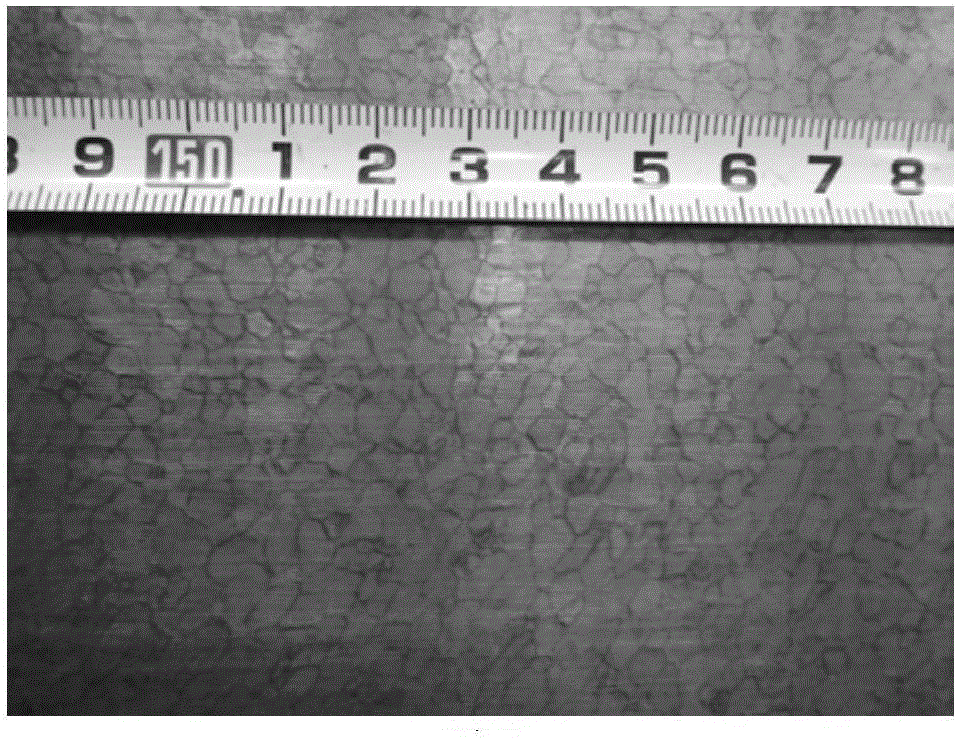

[0032] This embodiment is a Ti 2 The preparation method of AlNb series intermetallic compound alloy fine-grained ingot, what is prepared is a diameter of Ф540mm, a weight of 3000kg, and a nominal chemical composition of Ti-22at%Al-25at%Nb (wherein at% is atomic percentage content) Large size Ti 2 AlNb series intermetallic compound alloy fine-grained ingot, comprising the following steps:

[0033] Step 1. Proportioning raw materials according to the nominal chemical composition (Ti-22at%Al-25at%Nb), weighing 1396kg of titanium sponge, 327.97kg of aluminum beans, and 1277.22kg of niobium strips, dividing the above-mentioned raw materials into 30 parts, and then each Three kinds of raw materials were uniformly mixed, and then pressed into 30 electrode blocks.

[0034] Step 2: Using the plasma arc welding method, every 6 electrode blocks prepared in step 1 are welded into 1 consumable electrode, and 5 consumable electrodes are obtained.

[0035] Step 3: Melting the 5 consumable...

Embodiment 2

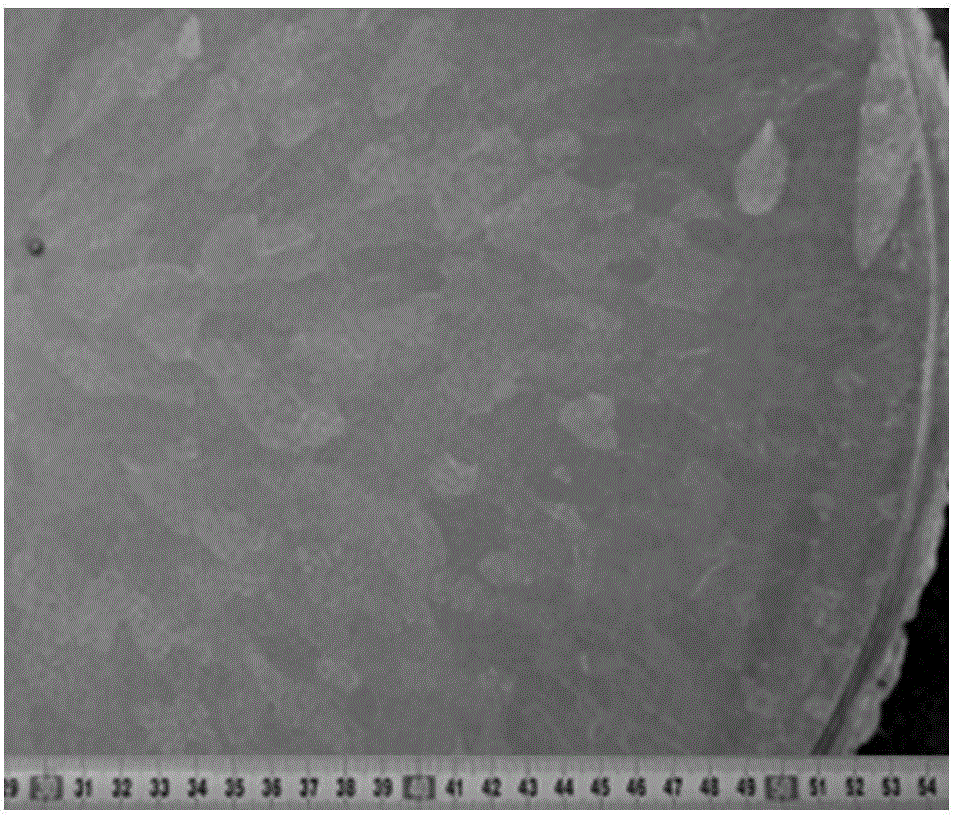

[0043] This embodiment is a Ti 2 The preparation method of AlNb series intermetallic compound alloy fine-grained ingot is prepared as a diameter of Ф460mm, a weight of 600kg, and a nominal chemical composition of Ti-22at%Al-25at%Nb (wherein at% is atomic percent content ) of Ti 2 AlNb series intermetallic compound alloy fine-grained ingot, comprising the following steps:

[0044] Step 1. Proportioning raw materials according to the nominal chemical composition (Ti-22at%Al-25at%Nb), weighing 279.22kg of titanium sponge, 65.59kg of aluminum beans, and 255.44kg of niobium strips, dividing the above-mentioned raw materials into 6 parts respectively, and then Each of the three raw materials is uniformly mixed and then pressed into six electrode blocks.

[0045] Step 2: Using the plasma arc welding method, the 6 electrode blocks prepared in Step 1 are assembled and welded into a consumable electrode.

[0046] Step 3: Melting the consumable electrode prepared in step 2 into a semi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com