Method for achieving cesium adsorption separation through extraction resin

A technology of resin extraction and adsorption separation, applied in the field of cesium liquid purification, can solve the problems of unsuitability for industrial scale-up production, complex preparation methods of adsorbents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for extracting and leaching resin adsorption and separation of cesium provided in this embodiment comprises the following steps:

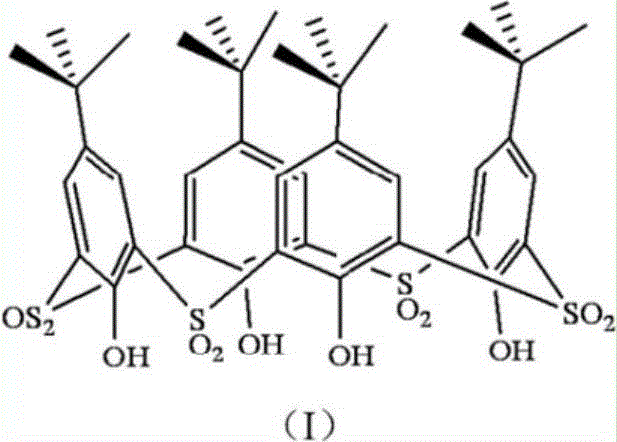

[0027] (1) Preparation of t-BAMBP extraction resin

[0028] Put 20g of polystyrene-divinylbenzene macroporous resin and 20mL of t-BAMBP in a container after washing with absolute ethanol, then add 20mL of petroleum ether, stir at room temperature for 10h, filter, and dry in an oven at 60°C Dry, make the t-BAMBP extraction leaching resin that is processed with sherwood oil;

[0029] (2) Adsorption process of cesium liquid

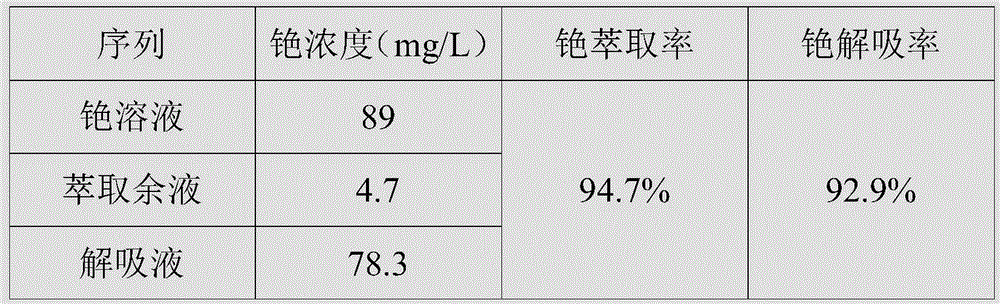

[0030] Take 40 mL of cesium solution with a concentration of 89 mg / L and add 20 g of t-BAMBP extraction resin treated with petroleum ether, adjust the alkalinity of the above cesium solution to 1.0 mol / L with sodium hydroxide, vibrate and stir for 6 hours, filter to obtain cesium adsorbed t-BAMBP extraction resin;

[0031] (3) Desorption process of cesium

[0032] Add 40mL concentration to the t-BAMBP extrac...

Embodiment 2

[0037] The method for extracting and leaching resin adsorption and separation of cesium provided in this embodiment comprises the following steps:

[0038] (1) Preparation of t-BAMBP extraction resin

[0039] Put 20g of polystyrene-divinylbenzene macroporous resin and 20mL t-BAMBP in a container after washing with absolute ethanol, then add 40mL of dichloroethane, stir at room temperature for 12h, filter, and place in an oven at 80°C Drying under the oven makes the t-BAMBP extracting resin treated with ethylene dichloride;

[0040] (2) Adsorption process of cesium liquid

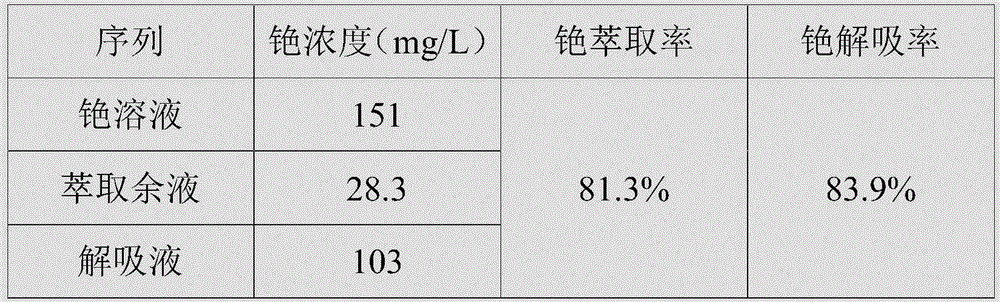

[0041] Take 40 mL of cesium solution with a concentration of 151 mg / L and add 20 g of t-BAMBP extraction resin treated with dichloroethane, adjust the alkalinity of the above cesium solution to 1.2 mol / L with sodium hydroxide, oscillate and stir for 4 hours, filter to obtain t-BAMBP extraction resin for adsorbing cesium;

[0042] (3) Desorption process of cesium

[0043] Add 40mL concentration to the t-B...

Embodiment 3

[0048] The method for extracting and leaching resin adsorption and separation of cesium provided in this embodiment comprises the following steps:

[0049] (1) Preparation of t-BAMBP extraction resin

[0050] Put 20g of polystyrene-divinylbenzene macroporous resin and 20mL t-BAMBP in a container after washing with absolute ethanol, then add 60mL of ethanol, stir at room temperature for 8h, filter, and dry in an oven at 90°C , make the t-BAMBP extraction leaching resin that handles with xylene;

[0051] (2) Adsorption process of cesium liquid

[0052] Take 40 mL of cesium solution with a concentration of 268 mg / L and add 20 g of t-BAMBP extraction resin treated with ethanol, adjust the alkalinity of the above cesium solution to 0.5 mol / L with sodium hydroxide, vibrate and stir for 8 hours, filter to obtain cesium-adsorbed t-BAMBP extraction resin;

[0053] (3) Desorption process of cesium

[0054] Add 40mL concentration of 1.0mol / L HCl desorbent to the t-BAMBP extraction re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com