High-silicon nitrogen-contained austenitic stainless steel and preparing method thereof

A technology of austenitic stainless steel and stainless steel, applied in the field of alloys, can solve the problems affecting the thermal processing performance and constraints of stainless steel, achieve good cold and hot processing performance, improve corrosion resistance, improve corrosion resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

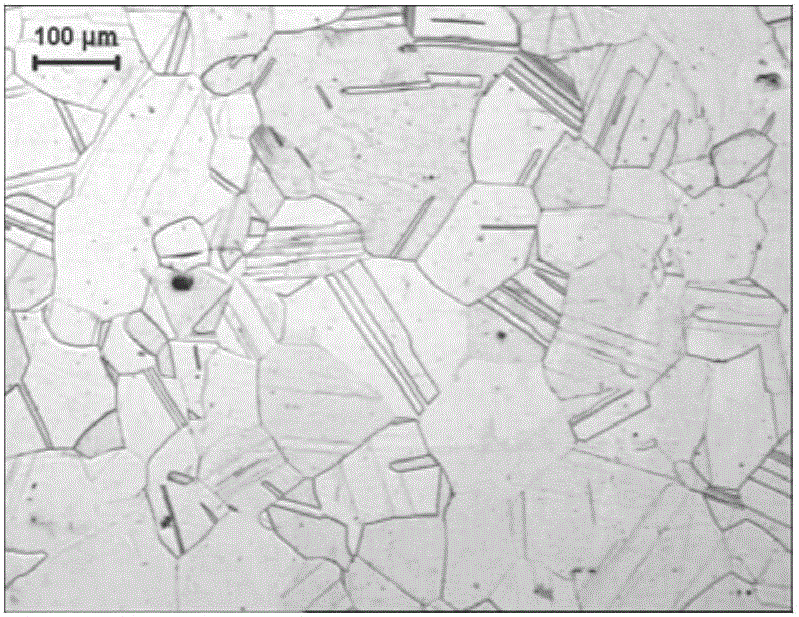

Image

Examples

preparation example Construction

[0019] The preparation method of the high-silicon nitrogen-containing austenitic stainless steel of the present invention comprises the following steps:

[0020] Smelting ingots: Put the raw materials with a good ratio into the smelting furnace for smelting, and use nitrogen as the protective atmosphere in the furnace; when using a vacuum induction furnace for smelting, add nitrogen as the protective atmosphere after refining, and control the pressure at 0.02MPa-0.05MPa, The nitrogen element in the alloy mainly passes through the granular Si 3 N 4 High-nitrogen alloy is added; when using other nitrogen-protected atmosphere smelting equipment for smelting, the nitrogen pressure should be controlled at 0.02MPa-0.1MPa; after smelting is completed, ingots are cast;

[0021] Hot processing of steel ingot: Homogenize the steel ingot at 1050°C-1200°C for 4-10 hours to fully eliminate the high-silicon precipitates in the ingot, so that the high-silicon inclusions in the steel ingot a...

Embodiment 1

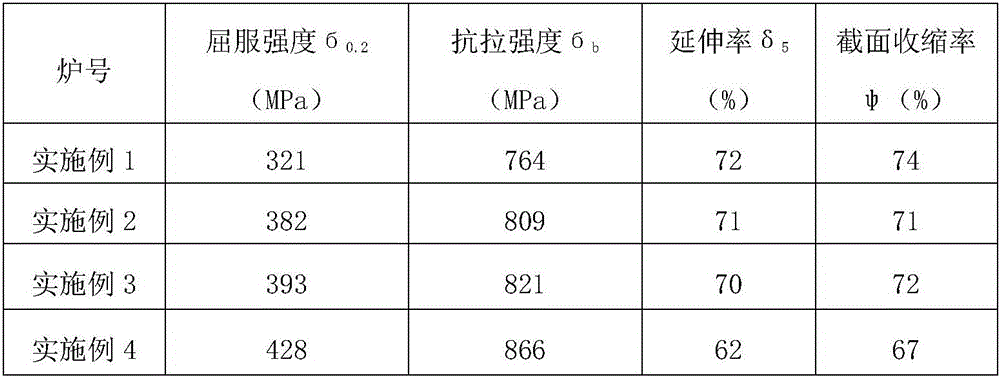

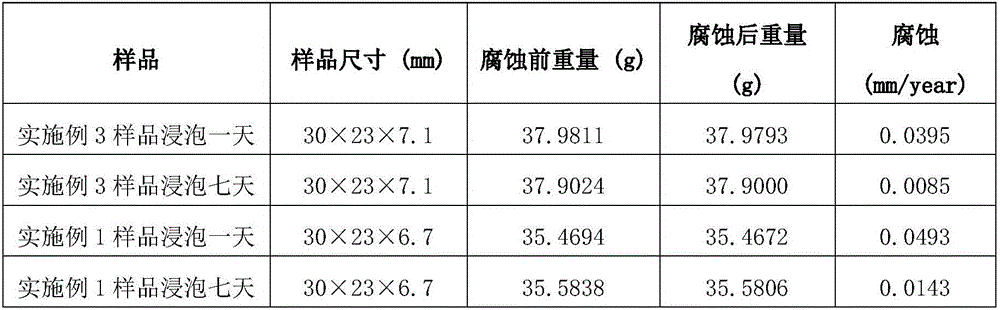

[0036] Embodiment 1: A kind of conventional high silicon stainless steel, as the comparison steel of the embodiment of the present invention, its chemical composition mass percent is: C0.021, Cr17.2, Mn1.78, Mo2.25, Ni18.1, Al≤0.02 , Si5.84, S0.0076, P0.011, balance Fe. Using conventional thermal processing technology and heat treatment process, samples are taken along the direction perpendicular to the rolling direction, and a test square sample with a plate thickness of 12mm and a size of 11mm×11mm is obtained. The mechanical properties of the sample are tested, and the mechanical properties of the sample are measured. Table 1, and samples were soaked in 90 ° 98% concentrated sulfuric acid for one day and seven days to test the corrosion rate, and the measured corrosion rate was listed in Table 2.

Embodiment 2

[0037] Embodiment 2: the high silicon nitrogen-containing austenitic stainless steel of the present invention, its chemical composition mass percent is: C0.019, Cr18.9, Mn2.63, N 0.15, Mo1.88, Cu 1.14, Ni 16.91, La0. 3, Al0.67, Si4.92, S0.0081, P0.014, the balance of Fe; smelting in a vacuum induction furnace of 1 kg, the protective nitrogen pressure is 0.01MPa, and the nitrided alloy is Si 3 N 4 , the heat processing process is: the alloy ingot is homogenized and heat treated at 1150°C ± 15°C for 4 hours, and then forged into a performance test plate in three fires. The thickness of the plate used in this example is 12mm, and the final forging temperature is 950°C; Yes: The test plate is sampled along the direction perpendicular to the processing direction, cut into 11mm×11mm test squares, solution treated at 1100°C±5°C for (1±0.1) hours, air-cooled or water-cooled to room temperature, and chromium, copper, molybdenum, Nitrogen and silicon compounds or inclusions are fully d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com