High-temperature-resistant flexible transparent conducting film, and preparation method and application thereof

A technology of transparent conductive film and conductive film, applied in the direction of vacuum evaporation plating, coating, sputtering plating, etc., can solve the problems of high thermal expansion coefficient, large surface roughness, low temperature resistance, etc., and achieve low thermal expansion coefficient, The effect of high transparency and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

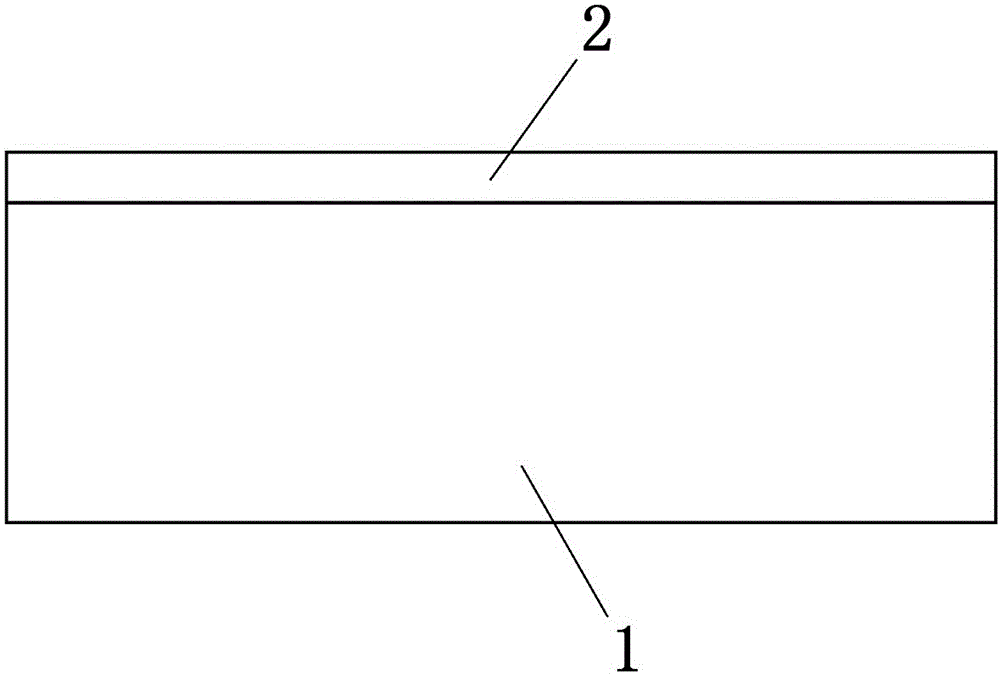

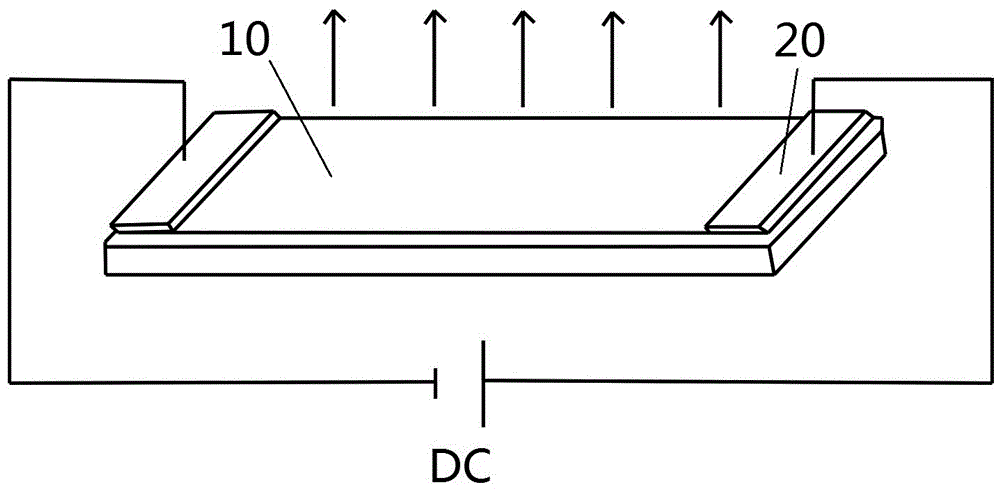

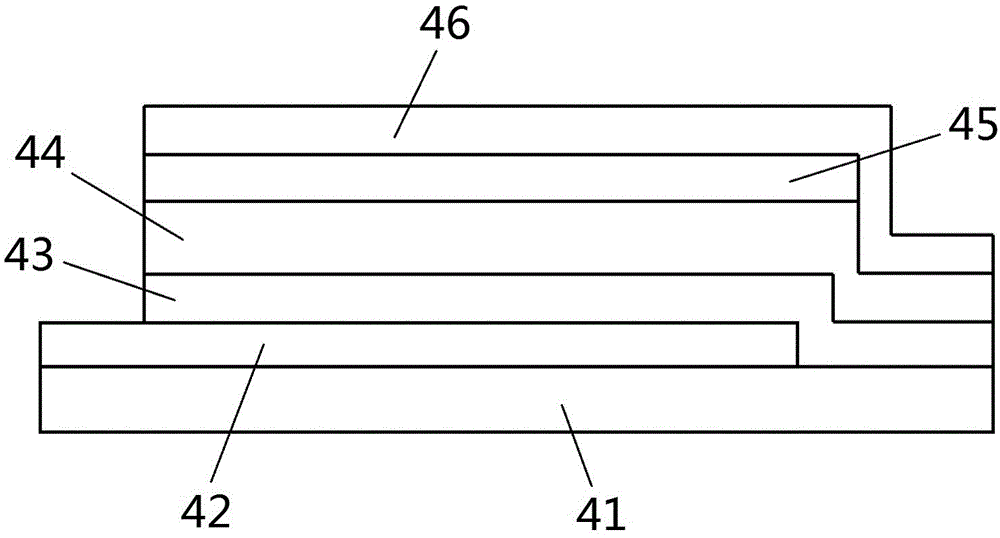

[0056] Example 1: The transparent conductive layer is 100 nm ITO

[0057] The high-temperature-resistant flexible transparent substrate uses a mica sheet with a thickness of 15µm, which can be directly peeled off mechanically without cleaning; a commercial ITO target with a purity of 99.99wt% is installed in the cavity of a pulsed laser deposition system, and it is glued with double-sided adhesive On the substrate holder (deposition at room temperature), install it in the cavity, adjust the target base distance to 50 mm; pump the cavity to keep the pressure in the cavity at 1.0×10 -4 Pa; adjust the optical path, start the excimer laser, focus the laser beam on the target in the cavity, and start depositing a film at room temperature with a film thickness of 100 nm; after the deposition, fill the cavity with high-purity oxygen to modulate Inflation and pumping volume, so that the gas pressure in the cavity is 10 Pa, the substrate is heated to a temperature of 500 °C for in-situ...

Embodiment 2

[0058] Embodiment 2: The transparent conductive layer is 200 nm ITO

[0059] The preparation process is basically the same as that described in Example 1, except that the thickness of the deposited ITO film is 200 nm. The sheet resistance of the obtained high-temperature-resistant flexible transparent conductive film is 40 Ω / □, and the average transmittance of visible light is 83%. The film structure and photoelectric performance are stable, and it is firmly combined with the mica substrate.

Embodiment 3

[0060] Embodiment 3: The transparent conductive layer is 50 nm ITO

[0061] The preparation process is basically the same as that described in Example 1, except that the thickness of the deposited ITO film is 50 nm. The sheet resistance of the obtained high-temperature-resistant flexible transparent conductive film is 300 Ω / □, and the average transmittance of visible light is 88%. The film structure and photoelectric performance are stable, and it is firmly combined with the mica substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com