Composite asphalt stress absorption membrane and preparation method thereof

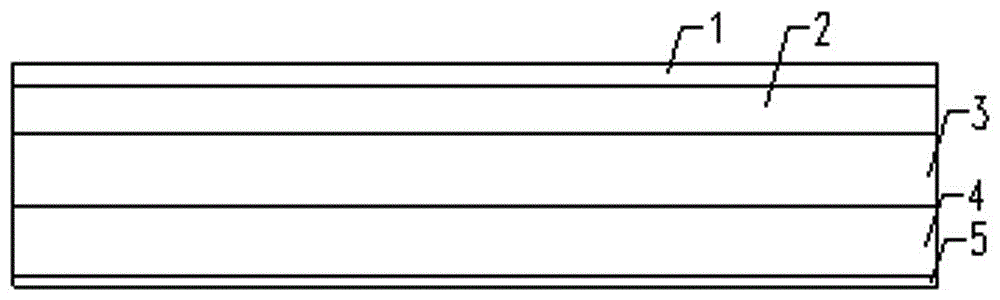

A technology of stress absorption and composite asphalt, which is applied in the direction of asphalt layered products, chemical instruments and methods, synthetic resin layered products, etc. It can solve problems such as engineering quality accidents and poor construction control, so as to prolong the service life and prevent road surface Cracks and associated damage, reducing the effect of opening deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1) Preparation of high molecular polymer modified asphalt for upper composite layer and lower composite layer

[0061] 1-1) Heat the SBS modified bitumen to 220℃ to melt and then transport it to the mixing tank;

[0062] 1-2) Add rubber powder and stir for 5 hours to make the rubber powder and SBS modified asphalt mix uniformly, during which the temperature in the mixing tank is maintained at 200-220℃;

[0063] 1-3) After the rubber powder and SBS modified asphalt are evenly mixed, add additive one and additive two and mix evenly for 1.5 hours;

[0064] 1-4) Add petroleum resin and stir 40;

[0065] 1-5) Add talcum powder and stir for 35 minutes;

[0066] 2) Combination of upper composite layer, lower composite layer and tire base

[0067] Spread the high-modulus tire base fabric, namely polyester filament geotextile or polyester fiberglass cloth, and immerse it in the asphalt pool, and attach the polymer modified asphalt in the asphalt pool to the upper and lower surfaces of the t...

Embodiment 2

[0072] 1) Preparation of high molecular polymer modified asphalt for upper composite layer and lower composite layer

[0073] 1-1) Heat the SBS modified bitumen to 220℃ to melt and then transport it to the mixing tank;

[0074] 1-2) Add rubber powder and stir for 6 hours to make the rubber powder and SBS modified asphalt mix uniformly, during which the temperature in the mixing tank is maintained at 200-220℃;

[0075] 1-3) After the rubber powder and SBS modified asphalt are evenly mixed, add additive one and additive two and mix evenly for 2 hours;

[0076] 1-4) Add petroleum resin and stir for 45 minutes;

[0077] 1-5) Add talcum powder and stir for 40 minutes.

[0078] 2) Combination of upper composite layer, lower composite layer and tire base

[0079] Spread the high-modulus tire base fabric, namely polyester filament geotextile or polyester fiberglass cloth, and immerse it in the coating pool, and attach the polymer modified asphalt in the coating pool to the upper and lower surface...

Embodiment 3

[0084] 1) Preparation of high molecular polymer modified asphalt for upper composite layer and lower composite layer

[0085] 1-1) Heat the SBS modified bitumen to 220℃ to melt and then transport it to the mixing tank;

[0086] 1-2) Add rubber powder and stir for 6.5 hours to make the rubber powder and SBS modified asphalt mix uniformly, during which the temperature in the mixing tank is maintained at 200-220℃;

[0087] 1-3) After the rubber powder and SBS modified asphalt are evenly mixed, add additive one and additive two and mix evenly for 2.5 hours;

[0088] 1-4) Add petroleum resin and stir for 50 minutes;

[0089] 1-5) Add talc and stir for 45 minutes.

[0090] 2) Combination of upper composite layer, lower composite layer and tire base

[0091] Spread the high modulus tire base fabric, namely polyester filament geotextile or polyester glass fiber cloth, and immerse it in the coating pool, and attach the polymer modified asphalt in the coating pool to the upper and lower surfaces of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com