Waterproof-antipollution outdoor plate and production method thereof

A technology of board and waterproof layer, which is applied in the direction of construction, building structure, floor, etc., can solve the problem of low compressive strength and achieve good waterproof and moisture-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

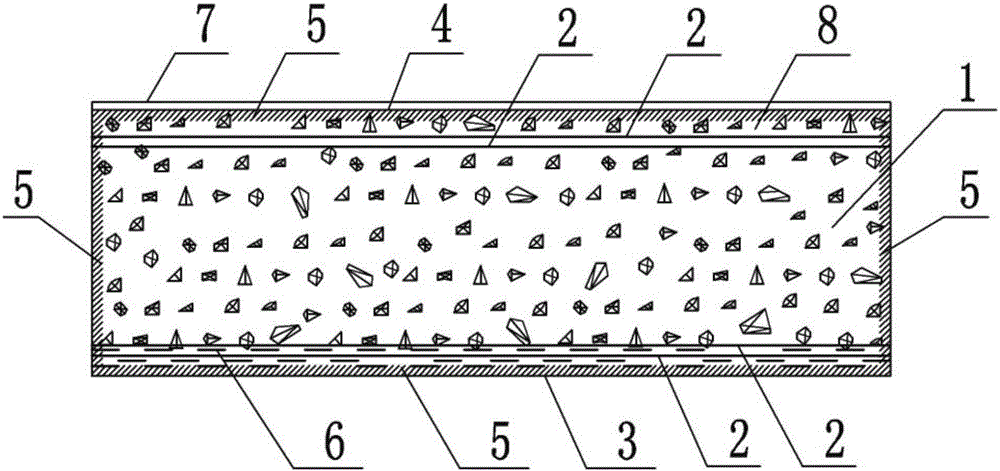

[0040] A waterproof and antifouling outdoor board of this embodiment, such as figure 1 As shown, it includes a plate body, the plate body includes glass fiber mesh cloth 2 arranged symmetrically on the upper and lower sides, and the slag magnesite cement material 1 is filled between the upper and lower glass fiber mesh cloths 2; The upper part of the glass fiber mesh cloth 2 is sequentially provided with a silicone waterproof layer 5, a sanding surface 4, and an anti-fouling coating 7. The gap between the glass fiber mesh cloth 2 and the sanding surface 4 is filled with water slag Sheet magnesite cementing material 8; the lower part of the lower glass fiber mesh cloth 2 is sequentially provided with a silicone waterproof layer 5, a natural surface layer 3, and a natural surface layer is provided between the organic silicon waterproof layer 5 and the natural surface layer 3 Slurry 6; The organic silicon waterproof layer 5 is provided symmetrically.

[0041] The water slag color c...

Embodiment 2

[0060] On the basis of the above-mentioned embodiment 1, this embodiment further illustrates the influence of the amount of the glass fiber mesh cloth 2 on the mechanical properties of the waterproof board of the present invention.

[0061] In this embodiment, step (2) is improved:

[0062] (2) Start to make waterproof and antifouling outdoor panels:

[0063] A. The waterproof and antifouling outdoor board is formed on the waterproof board production line, and the prepared natural surface slurry (6) is spread on the PVC or ABS substrate;

[0064] B. Press 3 layers of glass fiber mesh cloth (2) into the natural surface slurry (6), and the water slag magnesite cementing material (1) slurry is spread on the natural surface slurry (6);

[0065] C. Lay 3 layers of glass fiber mesh cloth (2) again, spread the slag color chip magnesite cementing material (8) slurry, and then spread the non-woven fabric;

[0066] D. After cutting, leveling, curing, curing, demoulding, cutting to four sides, curi...

Embodiment 3

[0072] On the basis of the above-mentioned embodiment 1, this embodiment further illustrates the influence of the amount of the glass fiber mesh cloth 2 on the mechanical properties of the waterproof board of the present invention.

[0073] In this embodiment, step (2) is improved:

[0074] (2) Start to make waterproof and antifouling outdoor panels:

[0075] A. The waterproof and antifouling outdoor board is formed on the waterproof board production line, and the prepared natural surface slurry (6) is spread on the PVC or ABS substrate;

[0076] B. Press 4 layers of glass fiber mesh cloth (2) into the natural surface slurry (6) slurry, and the water slag magnesite cementing material (1) slurry is spread on the natural surface slurry (6);

[0077] C. Place 4 layers of glass fiber mesh cloth (2) again, place the slurry of slag color chip magnesite cementing material (8), and then place the non-woven fabric;

[0078] D. After cutting, leveling, curing, curing, demoulding, cutting to four s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com