Polymer injection block oil-water well production and injection increase technology

A technology of oil-water wells and processes, which is applied in the direction of wellbore/well components, cleaning tools, drilling compositions, etc., which can solve the problems of single process, poor pertinence, and poor effect, and achieve a wide range of treatment and increase Reaction range, good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

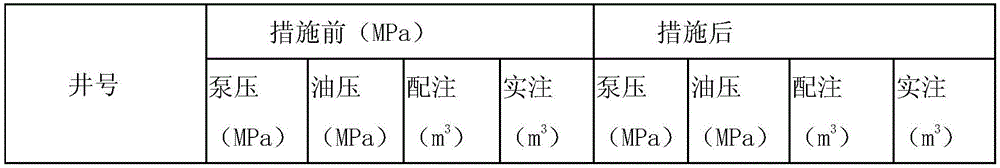

Embodiment 1

[0039] Well #1 Stimulation Injection Technical Solution:

[0040] (1) Use clean water 40m 3 Backwash well, wash away the sediment in the wellbore, and the water quality of the outlet is consistent with that of the inlet;

[0041] (2) In the way of positive well flushing, positively replace 5m of plugging solution 3 to the oil layer; close the casing gate;

[0042] (3) Squeeze in 120m of plugging remover 3 , shut down and react for 48 hours;

[0043] (4) Squeeze into acid solution 40m 3 , squeezed into clean water 80m 3 , the shut-in reaction is 40-60 hours, preferably 48 hours;

[0044] (5) open a well, bet.

Embodiment 2

[0046] Well #2 Stimulation Injection Technical Solution:

[0047] (1) Use 50m of clean water 3 Backwash well, wash away the sediment in the wellbore, and the water quality of the outlet is consistent with that of the inlet;

[0048] (2) In the way of positive well flushing, 8m of plugging solution is positively replaced 3 to the oil layer; close the casing gate;

[0049] (3) Squeeze in 142m of plugging remover 3 , shut down and react for 48 hours;

[0050] (4) Squeeze into acid solution 60m 3 , squeezed into clean water 90m3 , the shut-in reaction is 40-60 hours, preferably 48 hours;

[0051] (5) open a well, bet.

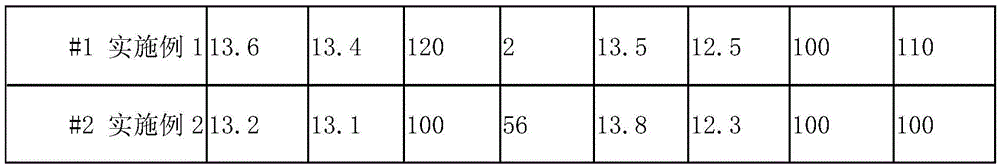

Embodiment 3

[0053] Well #1 stimulation technology plan:

[0054] (1) Use clean water 60m 3 Backwash well, wash away the sediment in the wellbore, and the water quality of the outlet is consistent with that of the inlet;

[0055] (2) In the way of positive well flushing, positively replace the plugging solution for 10m 3 to the oil layer; close the casing gate;

[0056] (3) Squeeze in 110m of plugging remover 3 , shut down and react for 48 hours;

[0057] (4) Squeeze into acid solution 30m 3 , squeezed into clean water 90m 3 , the shut-in reaction is 40-60 hours, preferably 48 hours;

[0058] (5) Open the well, lower the production string, and produce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com