LNG gas station cold, heat and electricity triple supply system

A technology of combined cooling, heating and power, gasification station, applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as ecological impact and waste of cold energy, save operating costs, improve power generation efficiency, Retrofit for easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be further described in conjunction with specific examples. The following examples are intended to illustrate the present invention but not to further limit the present invention.

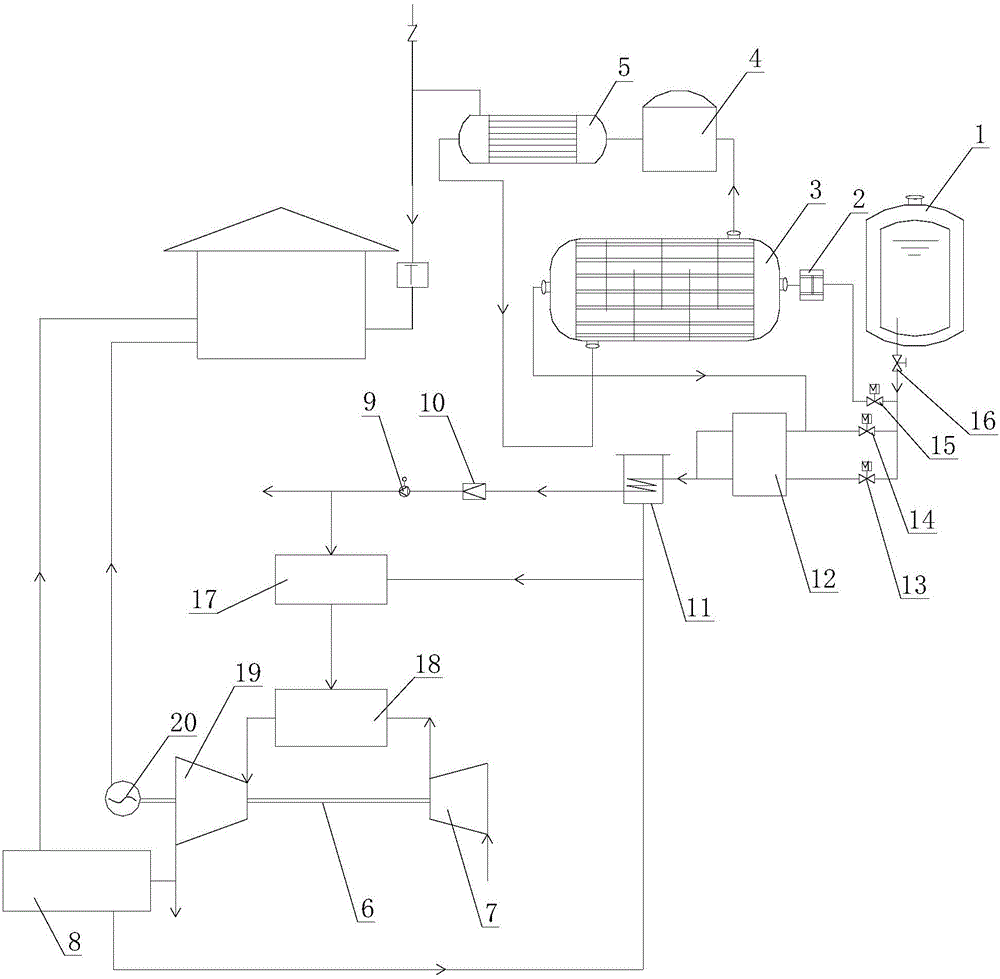

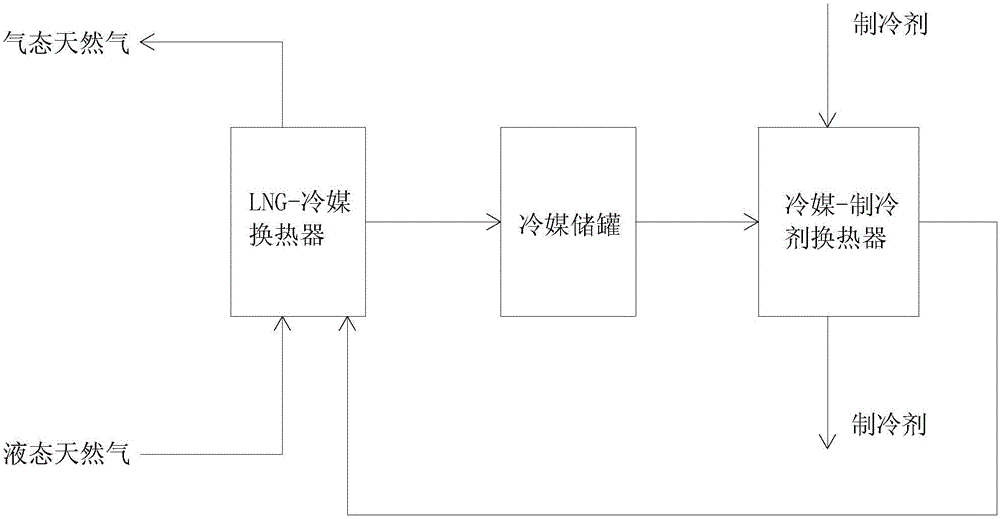

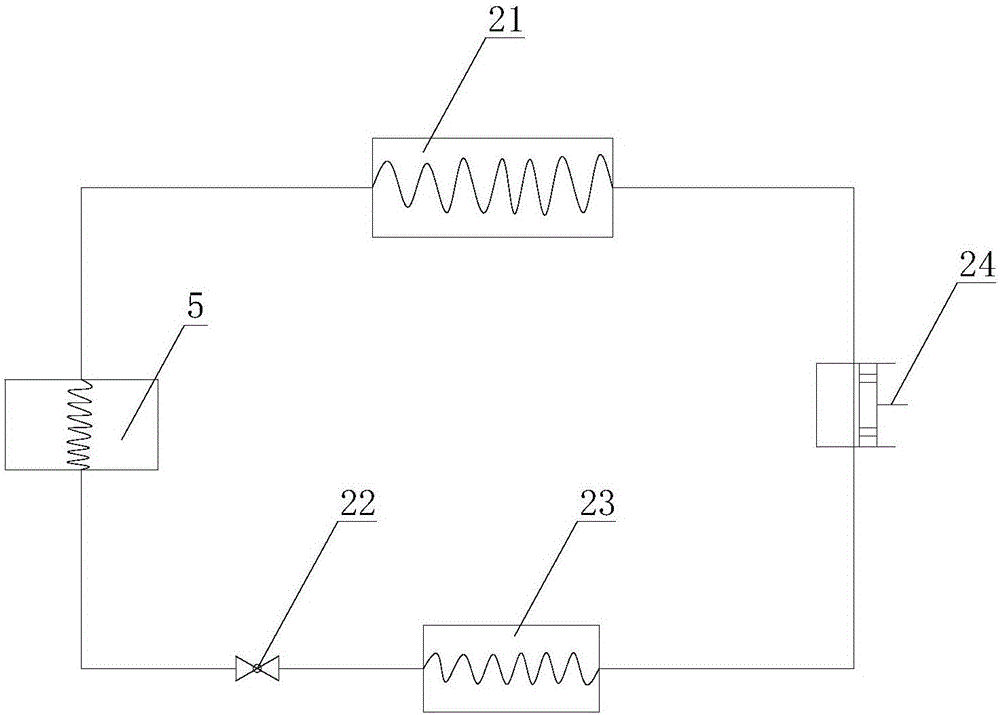

[0017] Such as figure 1 The shown a LNG gasification station cold, heat and power triple supply system, including LNG storage tank 1, exhaust fan 2, LNG-refrigerant heat exchanger 3, air temperature vaporizer 12, waste heat heater connected in sequence 11. Pressure reducing valve 10, flow detection device 9 and generator set, LNG passes through the shell side of LNG-refrigerant heat exchanger 3, the tube side of LNG-refrigerant heat exchanger 3 circulates refrigerant, LNG-refrigerant heat exchanger 3 A refrigerant storage tank 4 and a refrigerant-refrigerant heat exchanger 5 are connected in sequence between the exit and inlet of the tube pass. The refrigerant-refrigerant heat exchanger 5 circulates a refrigerant that provides indoor cooling, and an LNG storage tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com