Direct current low-nitrogen combustion device of coal water slurry boiler

A low-nitrogen combustion and coal-water slurry technology is applied in the direction of combustion methods, combustion types, and combustion equipment. It can solve the problems of not being able to effectively reduce nitrogen oxide emissions and meet emission standards, and achieve environmental protection and economical efficiency. Significant benefits, automatic control, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

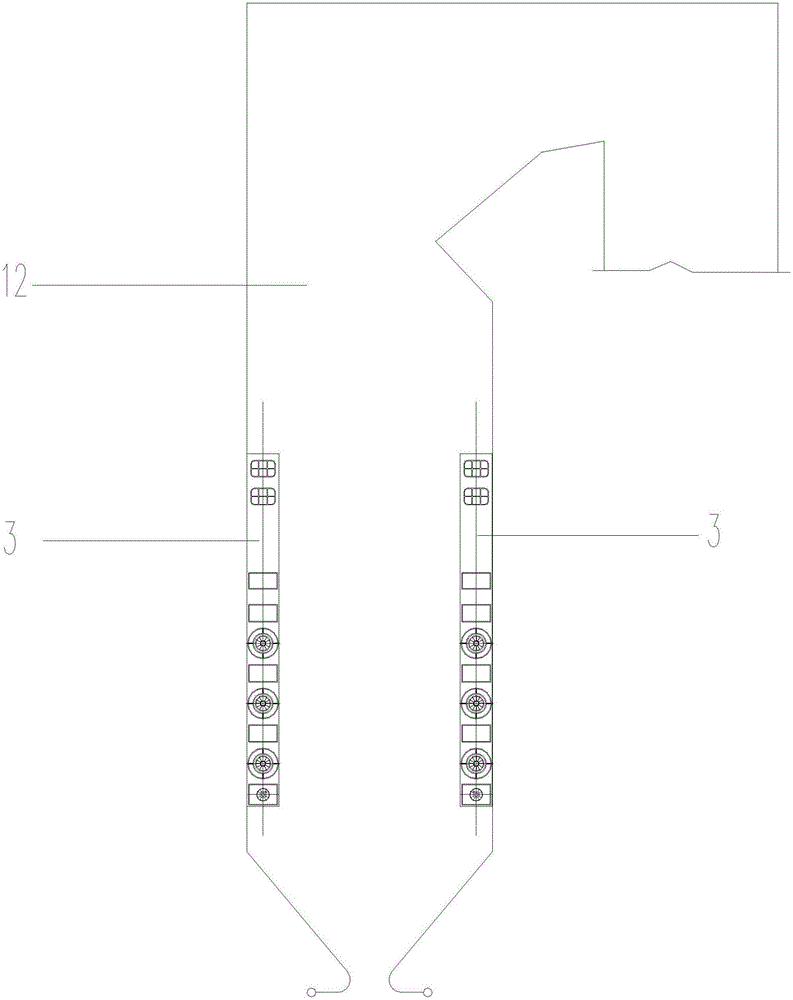

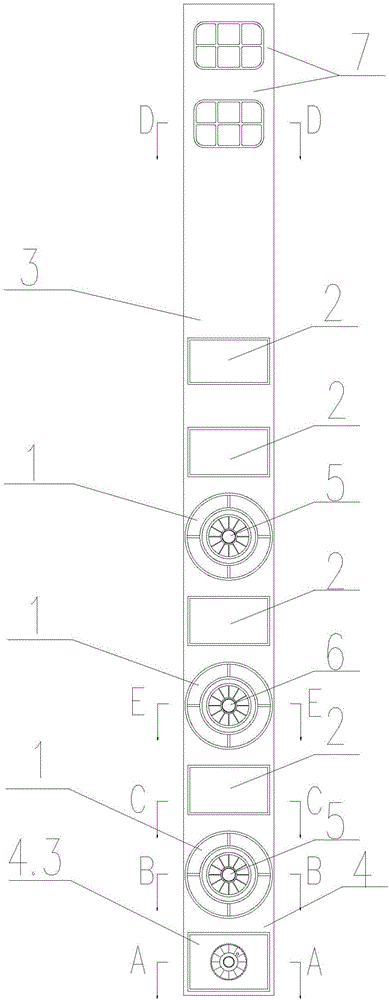

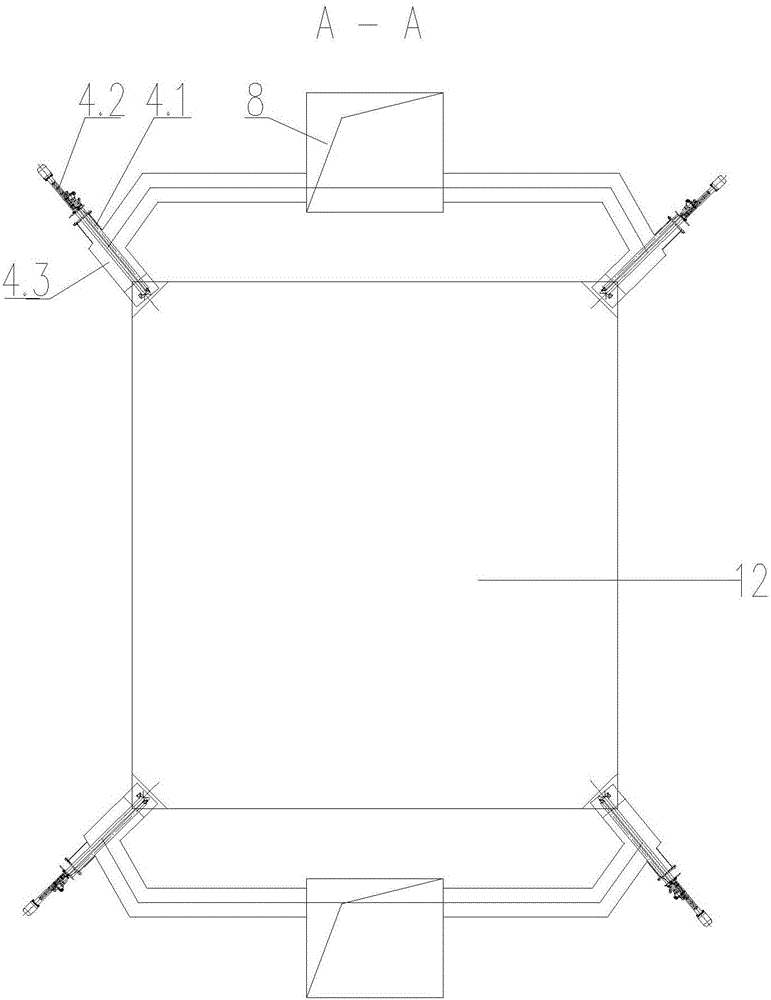

[0028] Such as figure 1 The once-through low-nitrogen combustion device of the coal-water slurry boiler shown in —7 includes device burners 3 arranged at four corners of the furnace 12, a coal-water slurry gun arranged on the device burner 3, along the longitudinal direction of the device burner 3 The secondary air inlet device 2 and the primary air inlet device 1 arranged alternately in the direction, the ignition air inlet device 4 arranged at the bottom of the burner 3 of the device, the ignition device 4.1 and the oil inlet are arranged at the air inlet of the ignition air inlet device 4 The gun 4.2; the device burner 3 also includes a separate burn-off air burner device 7 arranged on the top of the device burner 3, and the coal-water slurry gun includes a large coal-water slurry gun that is arranged on the device burner 3 at inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com