Optimization design device and optimization method for filtration-backwash parameters of polymer-containing sewage

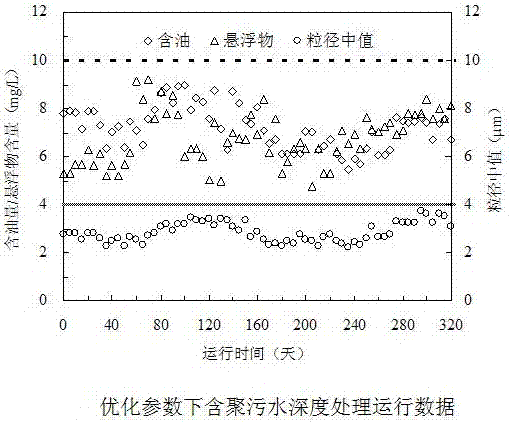

A technology for optimizing design and backwashing, applied in multi-objective optimization, design optimization/simulation, calculation, etc., can solve problems such as lack of scientific optimization design, rising backwashing pressure, and doubling of backwashing water volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing, the present invention will be further described:

[0063] like figure 1 As shown, this optimized design device for filtering-backwashing parameters of polymer-containing sewage includes a vertical sewage tank, a downward flow filter tank, an air compressor pump, a cylinder opening and closing system, an automatic control cabinet, a flow sensor, an inlet pressure sensor, and an outlet pressure sensor. The sensor, the forward filter pipeline is set between the raw water chamber of the vertical sewage tank and the water distributor on the top of the downflow filter tank, the forward filter sewage pipeline, the water collection chamber of the downflow filter tank and the vertical sewage tank Purified water pipelines are set between the purified water buffer chambers, forward filtered sewage pipelines are equipped with forward filtered incoming water valves, centrifugal pumps, water flow adjustment valves, flow sensors, overfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com