Methods, reagents and cells for biosynthesizing compounds

A technology of conversion and activity, applied in biochemical equipment and methods, organic chemistry, oxidoreductase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

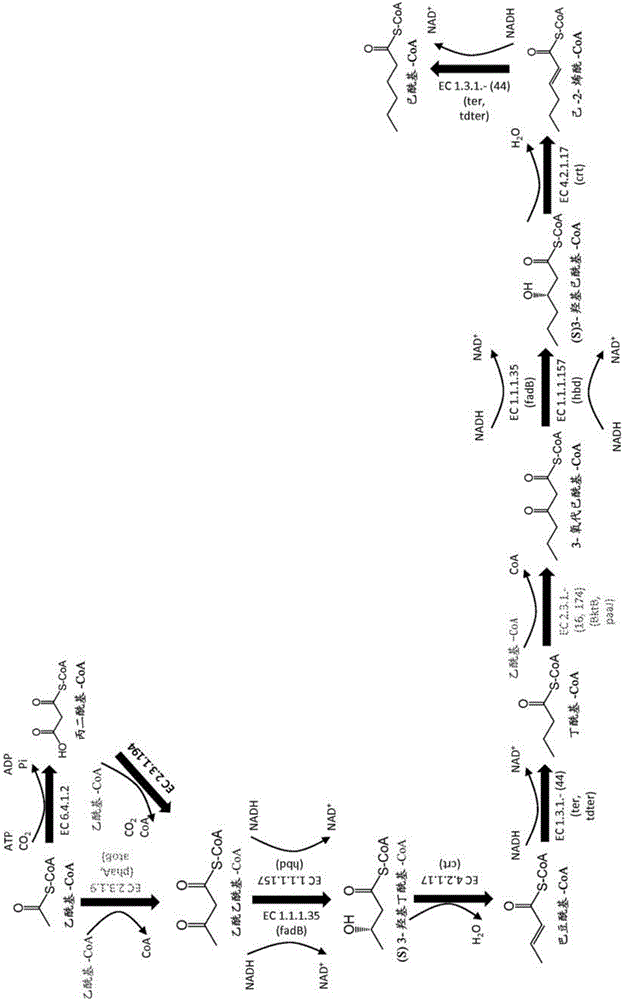

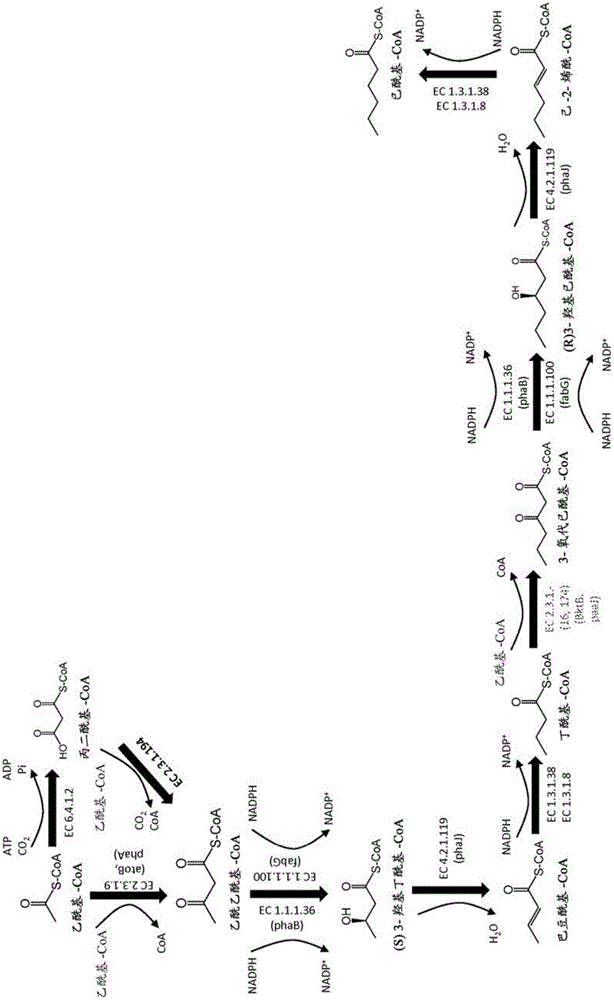

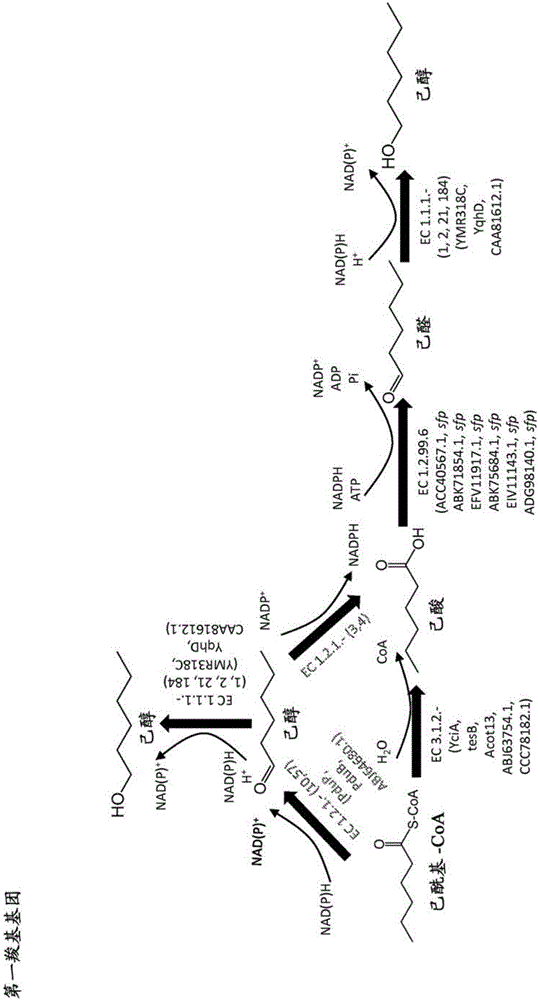

Method used

Image

Examples

example C4-9

[0190] where C 3-8 Hydroxyalkyl is as defined herein. Example C 4-9 Hydroxyalkanoic acids include, but are not limited to, 6-hydroxycaproic acid (ie, 6-hydroxycaproic acid), 5-hydroxycaproic acid salt (ie, 5-hydroxycaproic acid), 4-hydroxycaproic acid salt (ie, 4-hydroxycaproic acid acid), 3-hydroxyhexanoate (ie, 3-hydroxyhexanoic acid), etc. Those skilled in the art will appreciate that the particular form will depend on pH (eg, neutral or ionized form, including any salt form thereof). In some embodiments, C 3-8 A hydroxyalkyl group is a group having the formula:

[0191]

[0192] In some embodiments, one or more hydroxy-substituted (C 4-9 Alkyl)-OC(=O)-(C 3-8 The alkyl) ester method is a method that produces one or more hexylhydroxy hexanoates. In some embodiments, the method includes:

[0193] a) enzymatically converting hexanoyl-CoA to hexyl hexanoate; and

[0194] b) enzymatically converting hexyl caproate to any of 6-hydroxyhexyl caproate, 6-hydroxyhexyl 6-h...

Embodiment 1

[0360] Enzymatic activity of ω-transaminase using adipate semialdehyde as substrate and forming 6-aminocaproic acid

[0361] The nucleotide sequence encoding the His tag was added to the omega-transaminases from Chromobacterium violaceum, Pseudomonas aeruginosa, Pseudomonas syringae, Sphaeroides spp. Rhodobacter, and vibrio genes (see Figure 9 ), allowing the production of ω-transaminases with a HIS tag at the N-terminus. Each resulting modified gene was cloned into a pET21a expression vector under the control of the T7 promoter, and each expression vector was transformed into a BL21[DE3] E. coli host. The resulting recombinant E. coli strain was grown in a 250 mL shake flask culture containing 50 mL LB medium and antibiotic selection pressure at 37°C, shaking at 230 rpm. Each culture was induced overnight at 16°C with 1 mM IPTG.

[0362] Pellets from each induced shake flask culture were harvested via centrifugation. Each pellet was resuspended and lysed via sonication. ...

Embodiment 2

[0368] Carboxylate reductase Enzyme activity that uses adipate as a substrate and forms adipate semialdehyde

[0369] The sequence encoding the HIS tag was added to the genes from Segniliparus rugosus and Segniliparus rotundus encoding the carboxylic acid reductases of SEQ ID NO: 4 and 6, respectively (see Figure 9 ), making it possible to generate a carboxylic acid reductase with a HIS tag at the N-terminus. Each modified gene was cloned into the pET Duet expression vector together with the sfp gene encoding the HIS-tagged phosphopantetheinyltransferase from Bacillus subtilis, both under the T7 promoter. Each expression vector was transformed into a BL21[DE3] E. coli host, and the resulting recombinant E. coli strains were grown at 37°C in 250 mL shake flask cultures containing 50 mL LB medium and antibiotic selection pressure with shaking at 230 rpm . Each culture was induced overnight at 37°C using autoinduction culture.

[0370] Pellets from each induced shake flask cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com