High protein yoghurt and preparation method thereof

A high-protein, yogurt technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of protein particles and whey precipitation stability, and achieve the goal of increasing product added value, good product stability, and improving nutritional value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

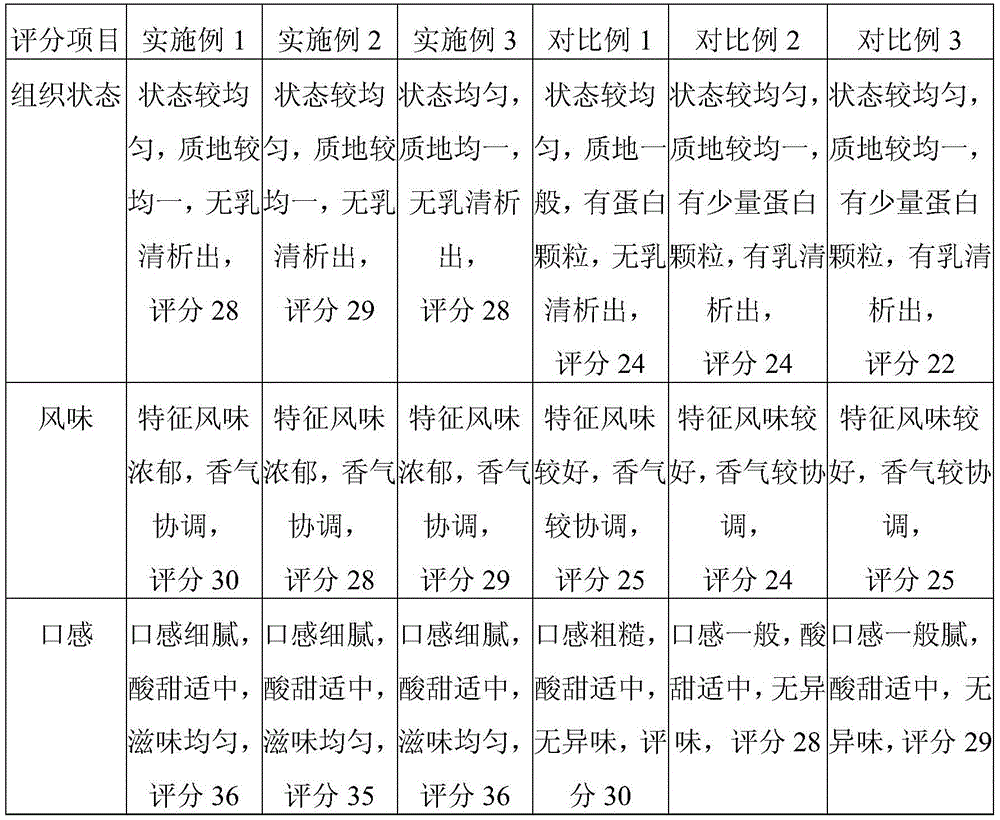

Embodiment 1

[0060] This embodiment provides a preparation of high-protein yogurt, which is prepared by fermentation with the following components as raw materials:

[0061] Based on the total weight of raw materials as 1000g, it includes 800g of fresh milk, 40g of glucose, 60g of white sugar, 50g of concentrated milk protein, 45g of cream, 3g of physically modified starch, 100U / T of starter (0.04U of Streptococcus thermophilus, Bulgarian milk Bacillus 0.04U, Bifidobacterium lactis each 0.02U), the total solid content in the ingredients is 28%, the fat content is 4.5%, the protein content is 7%, and the non-fat milk solid content is 23.5%.

[0062] The special flavor yoghurt is prepared by the following method:

[0063] 1) Standardization: Standardize the milk, and the protein index after standardization is 2.8-3.0;

[0064] 2) Add protein powder: hydrate after stirring for 15 minutes (50°C, 30 minutes);

[0065] 3) Addition of compound protease (papain: flavor protease = 1:1): add accor...

Embodiment 2

[0088] This embodiment provides a preparation of high-protein yogurt, which is prepared by fermentation with the following components as raw materials:

[0089] Based on the total weight of raw materials as 1000g, it includes 800g of fresh milk, 50g of glucose, 50g of white sugar, 60g of concentrated milk protein, 35g of cream, 5g of physically modified starch, 200U / T of starter (0.04U of Streptococcus thermophilus, Bulgarian milk Bacillus 0.04U, Bifidobacterium longum 0.04U, Lactobacillus casei 0.08U), the total solids content in the ingredients is 28%, the fat content is 4%, the protein content is 8%, and the non-fat milk solid content is 24%.

[0090] The high-protein yoghurt is prepared by the following method:

[0091] 1) Standardization: Standardize the milk, and the protein index after standardization is 2.8-3.0;

[0092] 2) Add protein powder: hydrate after stirring for 15 minutes (45°C, 30 minutes);

[0093] 3) Addition of compound protease (neutral protease: flavor...

Embodiment 3

[0116] This embodiment provides a preparation of high-protein yogurt, which is prepared by fermentation with the following components as raw materials:

[0117] Based on the total weight of raw materials as 1000g, it includes 800g of fresh milk, 35g of glucose, 58g of white granulated sugar, 80g of concentrated milk protein, 20g of cream, 7g of physically modified starch, 100U / T of starter (0.05U of Streptococcus thermophilus, Bulgarian milk bacillus 0.05U), the total solids content in the batching is 29%, the fat content is 4%, the protein content is 9%, and the non-fat milk solid content is 25%.

[0118] The special flavor yoghurt is prepared by the following method:

[0119] 1) Standardization: Standardize the milk, and the protein index after standardization is 2.8-3.0;

[0120] 2) Add protein powder: hydrate after stirring for 15 minutes (50°C, 30 minutes);

[0121] 3) Addition of compound protease (alkaline protease: papain = 1:2): add according to a certain ratio, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com