A high-strength, high-toughness, low-viscosity modified ECC concrete sound barrier board and its preparation method

A concrete and high-toughness technology, which is applied in construction, climate change adaptation, noise absorption devices, etc., can solve problems such as low tensile strength, difficult construction, and poor impact toughness, so as to improve compressive strength and toughness, and facilitate one-time The effect of permanent installation and improvement of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

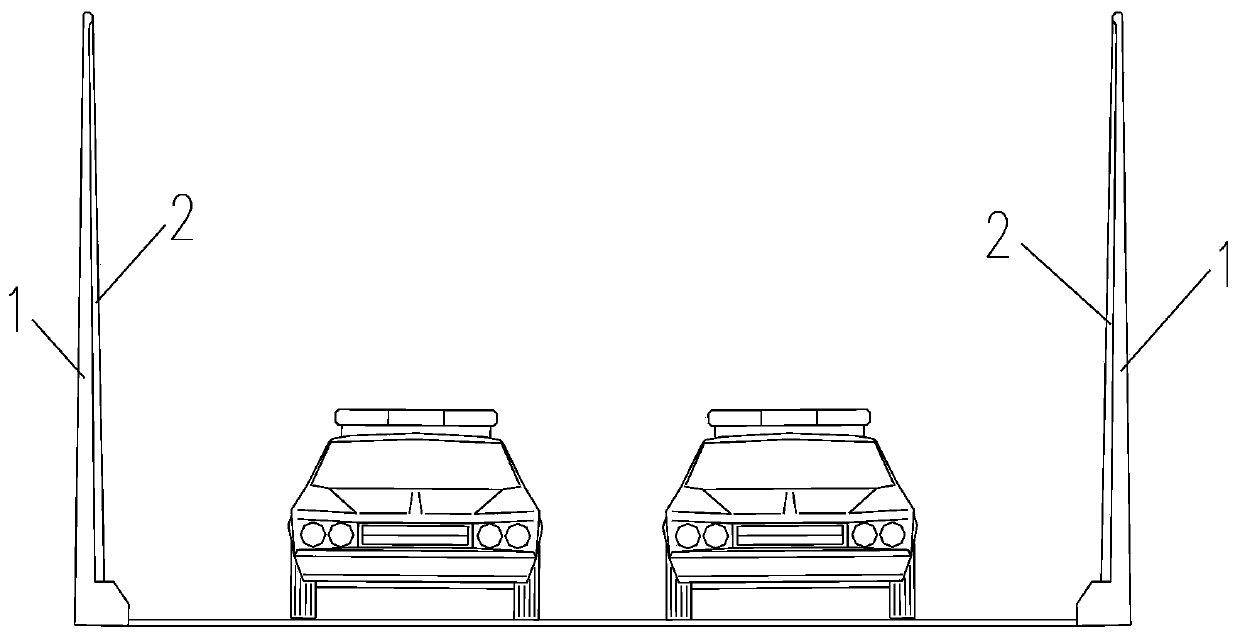

[0025] A high-strength, high-toughness and low-viscosity modified ECC concrete sound barrier plate, which is composed of a concrete unit plate 1 and a ceramic sand concrete sound-absorbing layer 2 covering the sound-receiving surface of the concrete unit plate 1, and the thickness of the concrete unit plate 1 is 4- 8cm, the thickness of the ceramic sand concrete sound-absorbing layer 2 is 2-5cm, and the concrete unit plate 1 is prepared from the following components by weight: cement: fly ash: microbeads: silica fume: quartz sand: water reducer: PVA fiber: steel fiber: water = 1:0.05:0.05:0.25:1.3:0.05:0.005:0.2:0.20;

[0026] The ceramic sand concrete sound-absorbing layer 2 is prepared from the following components by weight: cement: fly ash: microbeads: silica fume: ceramic sand: quartz sand: water reducer: PVA fiber: steel fiber: water = 1: 0.15:0.15:0.35:0.25:1.3:0.08:0.01:0.25:0.25.

[0027] The preparation method of the above-mentioned high-strength, high-toughness and...

Embodiment 2

[0033]The preparation method is the same as in Example 1, except that the concrete unit panel 1 is prepared from the following components by weight ratio: cement: fly ash: microbeads: silica fume: quartz sand: water reducer: PVA fiber: steel fiber: water = 1: 0.15: 0.15: 0.35: 1.3: 0.08: 0.01: 0.25: 0.25;

[0034] The ceramic sand concrete sound-absorbing layer 2 is prepared from the following components in weight ratio: cement: fly ash: microbeads: silica fume: ceramic sand: quartz sand: water reducer: PVA fiber: steel fiber: water = 1:0.05:0.05:0.25:0.2:1.3:0.05:0.005:0.2:0.20.

Embodiment 3

[0036] The preparation method is the same as in Example 1, except that the concrete unit panel 1 is prepared from the following components by weight ratio, cement: fly ash: microbeads: silica fume: quartz sand: water reducer: PVA fiber: steel fiber: water = 1: 0.12: 0.12: 0.32: 1.3: 0.08: 0.008: 0.24: 0.24; the ceramic sand concrete sound-absorbing layer 2 is prepared from the following components by weight ratio: cement: pulverized coal Ash: microbeads: silica fume: ceramic sand: quartz sand: water reducing agent: PVA fiber: steel fiber: water = 1: 0.12: 0.12: 0.32: 0.24: 1.3: 0.08: 0.008: 0.24: 0.24.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com