Rear-arranged impunity removing device of high speed steel wire production line

A production line and steel wire technology, applied in the field of high-speed steel, can solve the problems affecting the performance of high-speed steel, and achieve the effect of high qualification rate, clean production process and clean products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

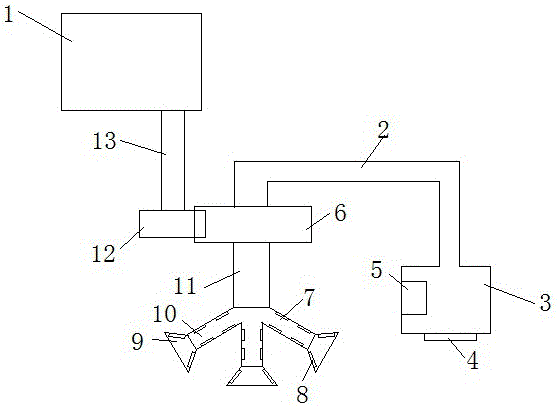

[0023] Embodiment one: if figure 1 As shown, a device for removing impurities at the rear of a high-speed steel wire production line includes a motor 1, a motor shaft 13 is arranged below the motor 1, and a driving wheel 12 is arranged at the end of the motor shaft 13. The driving wheel 12 and the driven wheel 6 rotate, from A hollow rotating shaft is provided below the driving wheel 6, a transmission shaft 2 is provided above the driven wheel 6, and a storage box 3 is provided at the other end of the transmission shaft 2, and a shunt 7 is connected to the end of the hollow rotating shaft 11, and a cover 9 is provided at the end of the shunt 7 , The inside of the middle separator and the cover 9 is provided with an iron filings attractor 8 . The motor shaft 13 is driven by the motor 1 to rotate, so that the driving wheel 12 drives the driven wheel 6 to rotate. After the driven wheel 6 rotates, the cover 9 at the end of the diverter 7 can contact a larger area as much as possib...

Embodiment 2

[0024] Embodiment 2: a device for removing impurities at the rear of a high-speed steel wire production line, including a motor 1, a motor shaft 13 is arranged below the motor 1, and a driving wheel 12 is arranged at the end of the motor shaft 13, and the driving wheel 12 and the driven wheel 6 rotate. A hollow rotating shaft is arranged below the driven wheel 6, and a transmission shaft 2 is arranged above the driven wheel 6. The other end of the transmission shaft 2 is provided with a storage box 3. The end of the hollow rotating shaft 11 is connected with a flow divider 7, and the end of the flow divider 7 is provided with a cover. 9. An iron filings attractor 8 is provided inside the middle separator and the cover 9 . The motor shaft 13 is driven by the motor 1 to rotate, so that the driving wheel 12 drives the driven wheel 6 to rotate. After the driven wheel 6 rotates, the cover 9 at the end of the diverter 7 can contact a larger area as much as possible to ensure that the...

Embodiment 3

[0027] Embodiment 3: A device for removing impurities at the rear of a high-speed steel wire production line, including a motor 1, a motor shaft 13 is arranged below the motor 1, and a driving wheel 12 is arranged at the end of the motor shaft 13, and the driving wheel 12 and the driven wheel 6 rotate. A hollow rotating shaft is arranged below the driven wheel 6, and a transmission shaft 2 is arranged above the driven wheel 6. The other end of the transmission shaft 2 is provided with a storage box 3. The end of the hollow rotating shaft 11 is connected with a flow divider 7, and the end of the flow divider 7 is provided with a cover. 9. An iron filings attractor 8 is provided inside the middle separator and the cover 9 . The motor shaft 13 is driven by the motor 1 to rotate, so that the driving wheel 12 drives the driven wheel 6 to rotate. After the driven wheel 6 rotates, the cover 9 at the end of the diverter 7 can contact a larger area as much as possible to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com